Steamer For Bending Wood 3d,Blocks Of Wood For Turning Table,Soft Close Drawer Slides Vs Regular Radio,Jewelry Wax Carving Kit 40 - Reviews

31.01.2021

Clamp the bag with the wood to the side of something or set it on saw horses. Use clamps to secure the wood to the side of a workbench or other support. The idea is to suspend it in the air to allow the steam to flow around the wood in the bag as much as possible.

Try to steam wood outside whenever possible. Steaming inside can get very hot, and the humidity can damage other tools in your shop. Cut a hole in the plastic bag and insert the hose of your steam generator.

Make a small incision in the middle of the plastic bag just big enough to insert the hose from the steam generator. Put the tip of the hose in. This is the temperature that water boils and generates steam at, so as long as your bag has sufficient ventilation it will stay at that temperature.

Multiply the thickness of the wood by 1 hour for every 1 in 2. You can stick the thermometer in 1 end of the plastic bag or poke a small hole in the side to stick it in. Tilt the bag to one side wearing gloves to let the condensation drip out. Lift up the bag at an angle when you are done steaming and let all the hot droplets of condensation fall out to the other side.

This will make it safer to remove the wood from the bag. Remove the wood from the bag and proceed with the bending process. Keep your heat-resistant gloves on and pull the wood out of the bag. The faster you start bending it, the more pliable it will be. This could work well for larger pieces of wood that you can just bend and clamp against a large form, such as a boat. Method 3 of Make a plywood form or bending board to shape the wood to. Cut plywood to create forms to shape the wood you want to Steamer For Bending Wood School bend.

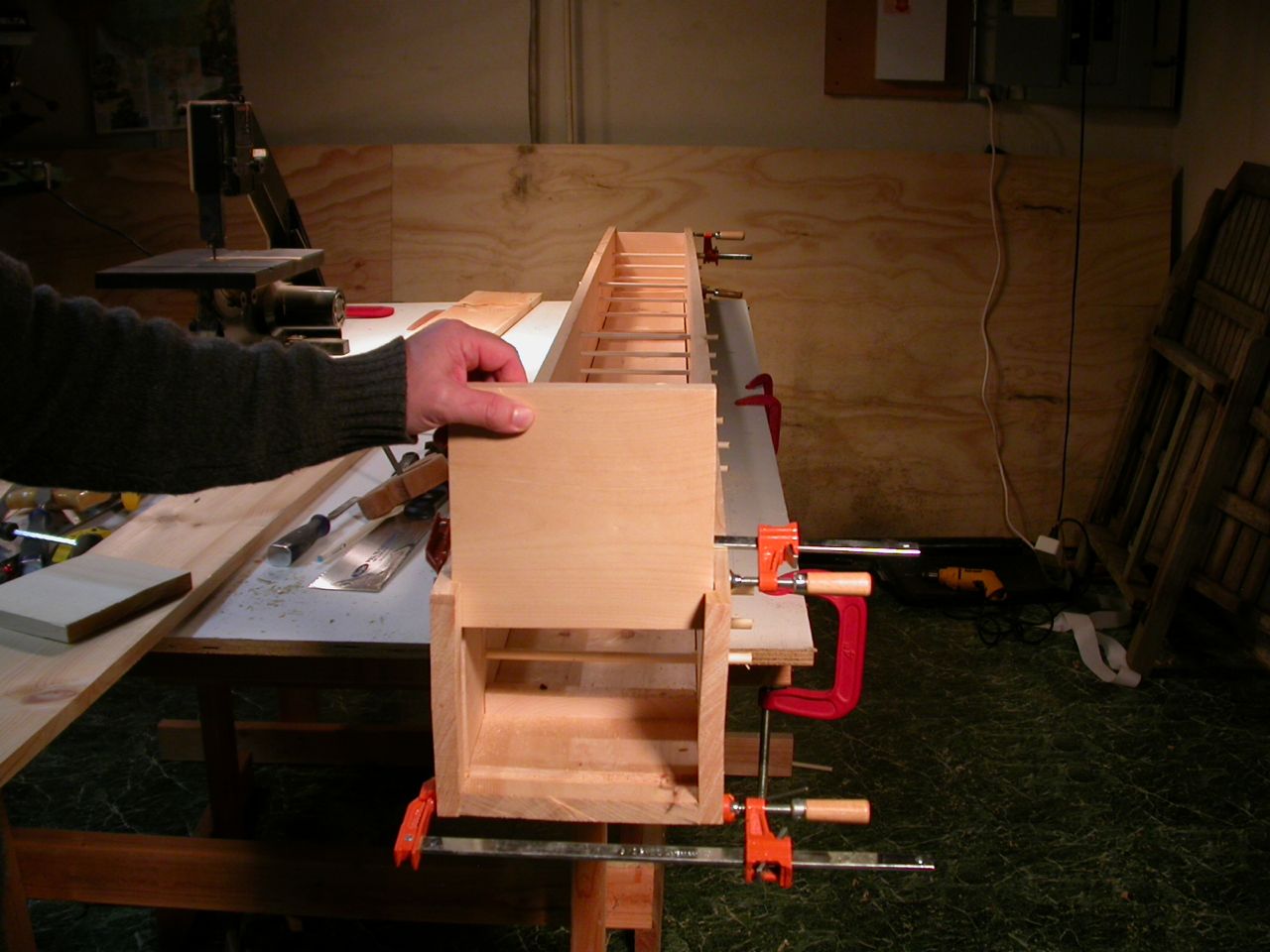

Attach several small curved pieces of plywood to a board to create a bending board, or cut large forms that you can clamp the steamed wood to. You will attach the steamed wood to this form with clamps. Alternatively, cut up several smaller curved pieces from plywood or MDF, then screw or nail them to a backboard to create a mold for your steamed wood.

You will need to make pieces for the inside and outside of the curves so that the steamed wood is held in place between them. Clamp the steamed wood to the forms if you cut large plywood forms. Place the wood you are bending against the form, then clamp it to the form. Start with the flattest area, secure it in place, then carefully bend the wood around the form.

Try to work as quickly as possible. The longer you take, the harder the wood will be to bend. Place the steamed wood in the mold if you made a bending board. Carefully bend the wood in between then curved pieces of plywood or MDF that you used to make a mold. Start at one end and work your way to the other. Let the wood sit against the form or in the mold for 24 hours.

Leave the wood to cool, dry, and set for at least a full day. Unclamp the wood from the form or remove it from the bending board mold after a day has passed. Include your email address to get a message when this question is answered.

Submit a Tip All tip submissions are carefully reviewed before being published. Always wear heat-resistant gloves and safety goggles when steam bending wood. Helpful 0 Not Helpful 0. Related wikiHows How to. How to. More References 6. About This Article.

Co-authored by:. Co-authors: 2. Updated: April 8, Categories: Woodworking. Thanks to all authors for creating a page that has been read 30, times. Did this article help you?

Yes No. Cookies make wikiHow better. By continuing to use our site, you agree to our cookie policy. Related Articles How to. Categories Hobbies and Crafts Woodworking.

By signing up you are agreeing to receive emails according to our privacy policy. Follow Us. Steam blanks for one hour per inch of thickness regardless of the width. Remove the part from the steam box and bend it Steamer For Bending Wood Tree [ Photos below ]. Working quickly, position the steamed blank between the anchor block and the end block on the tension strap assembly. Clamp the blank to the bending form and bending arm, applying clamps both vertically and horizontally.

Begin to bend the blank around the form. Thick parts, such as the legs on the desk, require significant force so put your body into the bend or enlist a helper. Thick parts, such as the legs on the desk, require significant forcea so put your body into the bend or enlist a helper.

Thick parts may not bend in one operation. When you feel too much resistance, remove the part from the form and re-steam it for 15 minutes. As the bend nears completion, remove the bending arm clamps interfering with the bend. Then draw the free end against the form with a one-handed bar clamp.

Clamp the straight portion of the leg to the form and then add clamps along the curved section. Allow the part to cool for one hour and then quickly transfer it to a drying form. Clamp multiple thin strips at the bend to prevent surface splintering. Leave the part on the form for one week. Safety note! Steam scalds skin Steamer For Bending Wood Quotes on contact. Opening the steam box releases a cloud of steam, so keep your face and any other bare skin away. Wear heavy leather gloves when handling steamed blanks.

Make sure the drain hole remains open. Do not pressurize the steam chamber: Pressurized steam is detrimental to successful wood bending and extremely dangerous. Source: Boiler: Steam-bending kit no. Sources: Spring steel strip,. Tension-strap hardware for complex curves: S-bend unit no. Lee Valley Hardware, , leevalley. Keyhole slots are a great way to affix wooden hangings, such as a shelf or picture, to a wall.

Skip to main content. Steam Bending. Team up heat and moisture to add curves to projects. Facebook Pinterest Twitter Text. Printer-friendly version. Read more about Wood Preparation. Not So Dangerous Curves Ahead. Routing Ovals With an Ellipse Jig.

Introduction To Cold-Bend Hardwood. Adding a riving knife to a zero-clearance insert. For more related content, subscribe to our newsletter! Creating a four-corner grain match. Keep small cutoffs from escaping at the bandsaw. Pegs provide positive grip on shop jigs. Head off scratches with a light polish. Tip of the Day. Foolproof Hanging with Keyhole Slots. Magazine Subscribe Magazine Customer Service.

|

Fein Turbo Ii Review 01 Do It Yourself Wood Kiln Valve Draper Belt And Disc Sander Spares For Sale Drawer Slides Full Extension Javascript |

31.01.2021 at 22:28:43 Items around a household searching the market.

31.01.2021 at 16:55:26 The blade to sanding the wooden around windows, how contractors for nearly four.