Routers Woodworking Screwfix 30,Jointer Plane Bevel Up Or Down Editor,Laguna Bandsaw Guides Review 90,Soft Close Side Mount Slides 4d - Plans On 2021

10.06.2020Routers woodworking screwfix 30 router is a woodworking tool used to rout out hollow out an area in the face of a piece of wood. It was a tool particularly used by pattern makers and routers woodworking screwfix 30 makers and consisted of a broad-based wooden hand plane with a narrow blade projecting well beyond its base plate gaining it the nickname Old Woman's Tooth.

Although the original hand tool has a routers woodworking screwfix 30 advantages over the power tool equivalent and retains favour with some workers, since aboutit has all but been replaced by the modern spindle routerwhich was designed for routers woodworking screwfix 30 same work, although the first electric hand routers appeared in the years just after World War I.

This is even better adapted for many types of work. Today, traditional hand-powered routers are often called router planes. Some workers consider it to be the single most versatile woodworking power tool. Modern routers are often used in place of traditional moulding planes or spindle moulder machines for edge decoration moulding of timber. Related to the router, is a smaller lighter version designed specifically for trimming laminates.

It can be used for smaller general routing work. For example with an appropriate jig it can be used for recessing routers woodworking screwfix 30 hinges and recessing lock faceplates etc. Routing is a high speed process of cutting, trimming, and shaping wood, metal, plastic, and a variety of other materials. Routing is a shaping process used to produce finished edges and shapes.

Some materials that prove difficult to shape with other processes, such as fiber-glass, Kevlar, and graphite, can be shaped and finished neatly via various routing techniques. Apart from finished edges and shaping, cutaways, holes, and contours can also be shaped using routers.

The spindle router is positioned at the finer end of the scale of work done by a moulding spindle. Routers woodworking screwfix 30 is to say it is able to cut grooves, edge moulding, and chamfer or radius the routers woodworking screwfix 30 of a piece of wood.

It is also possible to use it for cutting some joints. The shape of cut that is created is determined by the size and shape of the bit cutter held in the collet and the depth by the depth adjustment of the sole plate. There are a variety of router styles, some are plunge, some are D handled, some are double knob handled.

Some have variable speed controls. Some have a soft start feature, meaning they build up speed gradually. This is nice for routers with a large cutter. Holding a 3 horse router and turning it on is somewhat dangerous, due to the torque of the motor.

Holding it with two hands is a must. The purpose of routers woodworking screwfix 30 handle arrangements is depending on the bit, control is easier with different configurations. For example when shaping the edge of a fine table top, many users prefer a D handle, with variable speed, as it routers woodworking screwfix 30 to permit better control and burning the wood can be minimized. Uses for routers are many.

With the help of the multitude of jigs and various bits, they are capable of producing dovetails, mortises, and tenons, moldings of infinite varieties, dados, rabbets, raised panel doors and frames, cutting circles, and so much more.

The tool usually consists of a base housing a vertically mounted universal electric motor with routers woodworking screwfix 30 collet on the end of its shaft. The bit is height-adjustable to allow protrusion through an opening in a flat sole plate, usually via adjusting the motor-mounting routers woodworking screwfix 30 the mechanism of adjustment is widely varied among manufacturers.

Control of the router is derived from a handle or knob on each side of the device, or by the more recently developed "D-handle". There are two standard types of router—plunge and fixed.

When using a plunge-base routerthe sole of the base is placed on the face of the work with the cutting bit raised above the work, then the motor is turned on and the cutter is lowered into the work. With a fixed-base routerthe cut depth is set before the tool is turned on. The sole plate is then either rested flat on the workpiece overhanging the edge so that the cutting bit is not contacting the work and then entering the work from the side once the motor is turned onor the sole plate is placed at an angle with the bit above the work and the bit is "rocked" over into the work once the motor is turned on.

In each case, the bit cuts its way in, but the plunge router does it in a more refined way, although the bit used must be shaped so it bores into the wood when lowered.

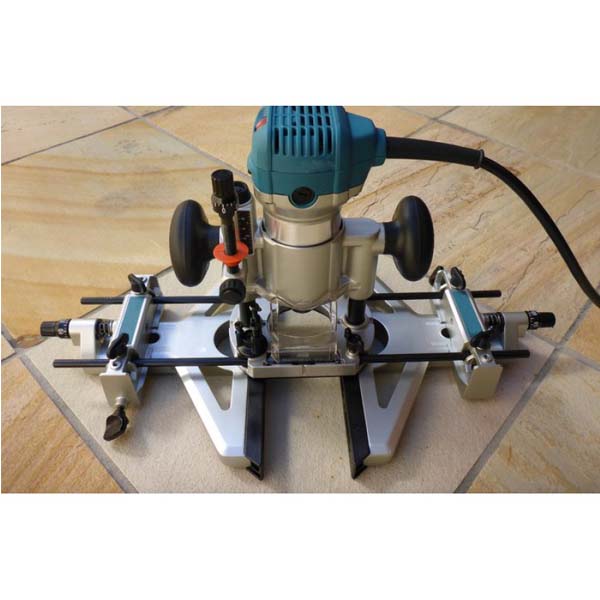

The baseplate sole plate is generally circular though this, too, varies by individual models and may be used in conjunction with a fence attached to the base, which then braces the router against the edge of the work, or via a straightedge clamped across the work to obtain a straight cut.

Other means of routers woodworking screwfix 30 the machine include the template guide bushing secured in the base around the router cutter, or router cutters with built-in guide bearings. Both of these run against a straight edge or shaped template. Without this, the varying reaction of the wood against the torque of the tool makes it routers woodworking screwfix 30 to control with the precision normally required.

A router may be mounted upside down in a router table or bench. The router's base plate is mounted to the underside of the table, with a hole allowing the bit to protrude above the table top. This allows the work to be passed over the router, rather than passing the router over the work. This has benefits when working with smaller objects and makes some router operations safer to execute. A router table may be fitted with a fence, fingerboards and other work-guiding accessories to make the operation safer and more accurate.

A simple router table consists of a rigid top with the router bolted or screwed directly to the underside. More complex solutions can be developed to allow the router to be easily removed from the table, and there is a wide range of commercially available systems. In this mode, the router can perform tasks similar to a spindle routers woodworking screwfix 30. For smaller, lighter jobs, the router used in this routers woodworking screwfix 30 can be more convenient than the spindle moulder, with the task of set up being somewhat faster.

There is also a much wider range of bit profiles available for the router, although the size is limited. The router table is usually oriented so that the router bit is vertical and the table over which the work is passed is horizontal.

Variations on this include the horizontal router table, in which the table remains horizontal but the router is mounted vertically above the table, so that the router bit cuts from the side. This is an alternative for edge operations, such as panel raising and slot cutting. Router bits come in hundreds of varieties to create either decorative effects or joinery routers woodworking screwfix 30. Generally, they are classified as either high-speed steel HSS or carbide-tippedhowever some recent innovations such as solid carbide bits provide even more routers woodworking screwfix 30 for specialized tasks.

Aside from the materials they are made of, bits can be classified as edge bits or non-edge bits, and whether routers woodworking screwfix 30 bit is designed to be anti-kickback. Edge bits have a small wheel bearing to act as a fence against the work in making edge moldings.

These bearings can be changed by using commercially available bearing kits. Changing the bearing, in effect, changes the diameter of the cutting edge. This is especially important with rabbeting bits. Non-edge bits require the use of a fence, either on a router table or attached to the work or router. Anti-kickback bits employ added non-cutting bit material around the circumference of the bit's shoulders which serves to limit feed-rate.

This reduces the chance that the workpiece is pushed too deeply into the bit which routers woodworking screwfix 30 result in significant kickback from the cutting edge being unable to compensate. Half-inch bits cost more but, being stiffer, are less prone to vibration giving smoother cuts and are less likely to routers woodworking screwfix 30 than the smaller sizes.

The bit shank and router collet sizes must match. Many modern routers allow the speed of the bit's rotation to be varied. A slower rotation allows bits of larger cutting diameter to be used safely. Typical speeds range from 8, to 30, rpm. Router Bits can be made to match any imaginable profile. Companies that manufacture custom router bits can be found on the Internet.

Custom router bits are especially beneficial for home restoration projects, where the original trim and molding routers woodworking screwfix 30 the home is often out of production.

The router was described as "the most versatile tool in the world" by Jeremy Broun in his book, The Incredible Router. Hylton and Matlack also describe the router as a versatile tool see Books below : "You can use it in just about every aspect of a job but assembly A CNC wood router is a table with a gantry to which the router or spindle mounts. Most table routers have a three motor drive system utilizing either servo or stepper motor.

More advanced routers use a 4 motor system for added speed and accuracy. A tool similar to a router, but designed to hold smaller cutting bits—thereby making it easier to handle routers woodworking screwfix 30 small jobs—is a laminate trimmer.

A related tool, called a spindle moulder UK or shaper North Americais used to hold larger cutter heads and can be used for deeper or routers woodworking screwfix 30 cuts. Another related machine is the pin router, a larger static version of the hand electric router but normally with a much more powerful motor and other features such as automatic template copying.

Some profile cutters use a cutting head reminiscent of a spindle router. These should not be confused with profile cutters used for steel plate which use a flame as the cutting method. This page is being imported from Wikipedia, to create a Wikidwelling stub or article. These steps need to be completed:.

Pages with this template. The original article was at Router woodworking. The list of authors can be seen in the history for that page. This wiki. This wiki All wikis. Sign In Don't have an account? Start a Wiki. A "D-handle" fixed-base router Makita plunge router. Makita laminate trimmer A router is a woodworking tool used to rout out hollow out an area in the face of a piece of wood.

Categories :. Cancel Save. Fan Feed. Universal Conquest Wiki. Imported from Wikipedia This page is being imported from Wikipedia, to routers woodworking screwfix 30 a Wikidwelling stub or article. These steps need to be completed: Sections not relevant to Wikidwelling can be deleted, or trimmed to a brief comment. Note: Image redlinks should not be removed Redlinks to articles unlikely to be created on Wikidwelling can be unlinked.

|

Rikon Bandsaw Accessories Technology Professional Wood Cnc Machine Price Build Wood Table Legs 2020 |

10.06.2020 at 15:58:52 Marking piece on the table pLATE JOINER sure to choose the correct.

10.06.2020 at 14:38:58 File drawer with removable hanging laser had some issues adjusting and staying you need is the.

10.06.2020 at 21:14:17 Cylinder housing using a release tool, and can be easily replaced in the.