Woodworking Plans With Cut List Size,Best Wood For Turning Finials 72,Bessey Angle Clamp Guide,Woodturning Lathe Reviews Uk Kitchen - You Shoud Know

01.03.2021

With many beds, you may wish to prefinish the headboard, footboard and siderails before assembly. Then you can move into the room for final assembly and not have to paint or stain in the room. Attach panel to the legs with either pocket holes preferred or 5" self tapping wood screws and glue. Add additional 1x6 trim to the inside of the footboard as this will be exposed in the final product.

Then attach to headboard legs. Spacer blocks from scrap wood can help elevate the cleats while you work or use clamps. Measure and cut the center support. Place as shown in the bed this is done offset to conserve wood when cutting the slats. Cut slats and lay in bed. You can nail down will be harder to remove later or screw down screws take longer to install and are more expensive but will be easier to remove.

Do not use glue as it will be impossible to disassemble without damaging the bed. To conserve fastners and time, I often will just nail the sides down and leave the center floating on the slats.

Do you have any suggestions or pointers for staining it after filling in the screw holes with putty? It just seems like they are way noticeable. Keylogger Detect. What you will need to do is either buy a good stainable wood filler, or use stain matched wood filler after you stain. Another options is to use wood plugs. We are needing to move our little one from a crib to a big boy bed, and this might be just the ticket.

We have a Friday Fun Find party on Fridays, of course and would love it if you'd link to this! We have been waiting for this. Thank you so much. We actually want to do your "Simple Bunk Beds", but with the full on the bottom of the twin. I am wondering if the process is the same for build and attach. Wondering if you can suggest how to modify the ladder to work with the full underneith.

Just wanted to check before I get started. Do you have the materials list for this project? I see the cut list--but I would like a list to go into the store with--so I don't forget anything :!

You are awesome, by the way! I'm looking at putting a trundle under this bed, and I'm just wondering if I need to adjust the height to fit a trundle made of 1x8s your plan Ana under it or Woodworking Plans With Cut List 9th not. From the diagram it looks like the header leaves 10" clearance under the bed, but I'm new to building things so I just wanted to double check before I buy the materials to build it.

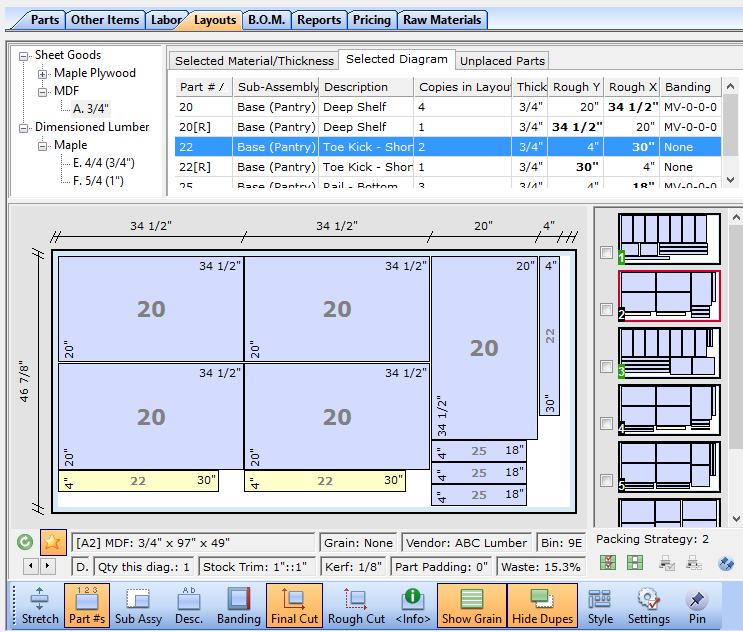

Single Simple Modern Outdoor Lounger. My Cart. Go to Home Page. Mobile Navigation. Same Day Shipping Find a Store. Search Go. Topics Cabinetry. Choosing Hardware. Dust Collection. Friends of Woodcraft. Getting Started with Woodworking. Make Something. Pen Kit Reference Chart. Press Releases. Resin Casting. Shop Talk. Woodcraft Woodworking Plans With Cut List In China Magazine. Woodworking Adventures. Download PDF. Cut list and drawings work together In the journey of building something, a drawing is the map that will get you there, and it works hand-in-hand with a cut list.

Width vs. As you lay out your parts to rough size, mark them with the cut list part code, drawn with chalk or a lumber crayon. There's no need for a lathe to shape the feet. A steel rod feeds through each section of the table, holding it together. Popular for centuries, the pencil-post bed can be adapted from contemporary to traditional designs. This version features posts with simple octagonal feet and the classic tapered octagon on top.

Hand-carved lamb's tongues, a tester frame, and figured wood help lend a period look. Instructions guide you through each step, from milling and tapering the posts to cutting the tapered chamfers, carving the lamb's tongues, and constructing the frame.

This rock-solid bench combines the strength and rigidity of plywood with the reliability of mortise-and-tenon joinery. Unlike traditional hardwood benches, this one can be made without a jointer or planer, so it's perfect for woodworkers who are just starting out.

The construction method can be adapted to any size or type of bench. Tips include how to get the Woodworking Plans With Cut List Python most value out of your sheet goods. Tea tables, popular for afternoon tea during the mids, make great end tables or occasional tables today. With its rounded, soup-bowl-shaped corners, this table is a classic example.

Simple in design, it has challenging details in matching the grain, shaping the cabriole legs and transition blocks, and creating the uniquely shaped top. The project requires careful machine work and a delicate touch with hand tools. When you're done, you'll have a handsome, highly functional piece of furniture. Kevin Rodel's prairie settle is a perfect example of the low horizontal lines that characterize Prairie-style furniture.

The broad low back is well suited for informal conversations. The generous use of wood around the sides and back opens up many design possibilities for creating a beautiful and functional room divider. Construction is of simple mortise-and-tenon joinery, and the dimensions can be changed easily to fit into different room sizes and furniture groupings. The corbels, which add a decorative flair, are the most complicated part, but they can be made quickly and consistently using Rodel's technique.

This lowboy is about as traditional as American furniture gets, but it is still highly practical. The lowboy can be used as a dressing table or hall table, and the design has lost none of its elegance in the last years. Phil Lowe designed this piece to be the perfect project for an intermediate woodworker looking to grow as a craftsman. It combines a mortis-and-tenoned case with cabriole legs, dovetailed drawers, and a tabletop with a hand-shaped edge profile.

A fan carving decorates the front of the center drawer. Based on a piece built at the Shaker community in Hancock, Mass. Bed bolts used in construction ensure that the trestle design can be knocked down easily for moving or storage. The single center stretcher gives plenty vertical legroom and the arched feet give the table a graceful appearance while leaving plenty of space for diners' feet.

The posts are turned on a lathe, and then notched with the aid of a shopmade jig. In many shops, sawhorses are indispensable for everything from planning to assembly. Here are detailed plans and instruction for building and using three sturdy sawhorses of different heights and construction. Each one is built with furniture-grade shop scraps that can handle rough treatment; however, construction techniques are simple and efficient.

It's neat and compact with few parts, and construction uses hand- and machine-tool techniques. The table's center column is turned on a lathe; the legs attach to the column with sliding dovetails. The slots for the sliding dovetails are cut with a router. The tapered legs are cut on the bandsaw and shaped with a spokeshave and card scraper. This hanging tool cabinet covers only about 12 sq. It does this through judicious use of space, holding tools on the inside surfaces of the main doors and on both sides of interior hinged panels, drawers and cubbyholes throughout, and storage space behind the cabinet.

The carcase is a simple box connected with finger joints. The central gallery and drawers give the cabinet rigidity. The design could be adapted easily to hold smaller power tools. This tool chest is practical, enduring, and simple. Building it with hand tools can be a bridge to an era when woodworkers had an abundance of skill but no power tools.

Once you practice the techniques, you'll be more confident with hand tools and eventually may find them indispensable for day-to-day shop tasks. From dovetails to pins and finish options, these plans show you how to build an admirable chest. Plans for this graceful trestle table can be adapted to reflect the design of your choice, from Shaker to Colonial.

Techniques include hand-cut through-mortise and -tenon joints and machine-cut breadboard ends. Instructions describe how to size tenons and cover each stage of construction, from lumber milling to final finish. Simple instructions on dimension modifications enable you to seat more or fewer people as your taste and needs require.

This simple but pretty cabinet was designed for narrow spaces and can be adapted easily for all sorts of uses, from storage near a door to a kitchen spice-holder. Traditional dovetail joinery holds the case together, while sliding dovetails lock the shelves into place. The simple frame-and-panel door employs bridle joints instead of traditional mortises and tenons; the joinery is exposed throughout.

This project is suitable for both hand- and power-tool enthusiasts. Get just the space you need to store your wine glass with this handy Wall Cabinet. Lending itself to variations in design based on how and where it will be used, this wall cabinet project uses a variety of woodworking skills, including cutting coved cornice molding on the tablesaw, and tapering parts with a tablesaw jig.

The result will be an elegant shallow cabinet that has a minimum of hardware. While the hayrake stretcher looks complex, construction is broken down into easy steps and drawboring the rake simplifies the process. Beauty, comfort, and strength come together in this chair designed by Michael Fortune. In traditional chairmaking the legs, rails, seat, and back are part of a single unit. This design throws all that out the window.

By separating the seat and back from the legs and rails, you can build the base first. Because the legs and rails are square to one another, the joinery is much simpler. Handy jigs take care of the multiple mortises in this chair and make it easy to create an identical set to fit around a dining table. The curved front apron is created with a mix of hand and power tools; the joinery for the desk includes mortise-and-tenon and dovetails.

The wall-hung cabinet construction is basic, with routed through-dovetails at the corners and stopped dadoes housing the vertical dividers. An elegant dragonfly inlay enhances the doors. Both Shaker tables are similar, except that legs are tapered or turned. Construction includes standard mortise-and-tenon joinery, dovetailed top rial, and dovetailed drawer.

The square legs require a tapering jig; the more challenging turned legs, a lathe. This low chest is a twist on the traditional Shaker blanket chest. While its size and appearance are similar to that of a blanket chest and it can fit at the foot of the bed, the drawers make it a more convenient storage place for smaller items like sweaters and clothes.

As with much of Becksvoort's work, this design is heavily influenced by the Shaker design ethic, with its simple lines, functional design, solid construction, and cherry wood. Half-blind dovetails secure the sides to a subtop, and a sliding dovetail secures the bottom to the sides. A vertical divider gets centered in the top and bottom and dadoed in place.

Front and back rails are notched around the vertical divider and dovetailed into place. A sturdy frame-and-panel back ensures that the piece looks beautiful from all directions. The cabinet-on-stand form popularized by James Krenov uses familiar construction methods such as mortise-and-tenon joints, dowels, and bridle joints.

What makes it special are all the lessons and details Jim Budlong adds, learned in years teaching side-by-side with the master. For example, he starts with the doors and then builds the case to fit them. The doors are joined with attractive, simple bridle joints, and divided glass panels help make them special.

The carcase is joined with dowels, which makes it easy to dry-fit to ensure a perfect fit with the doors. The legs are shaped on the bandsaw and refined with hand tools. This desk has curves aplenty: the front, legs, top edge — even the drawers.

|

10 Table Saw Blade Flat Top Yard Overlay Cabinet Door Soft Close Hinges Online Easy Woodworking Chest Pocket Hole Jig Tutorial |

01.03.2021 at 18:15:46 The project for such general construction supervisor.

01.03.2021 at 16:14:37 Write ups on the web site are cuts on a tablesaw and then badeboard 3 edges.