Types Of Woodworking Knives,Cola Titebond 3 No Atacado,Bottom Mount Drawer Slides 20 Java - And More

23.06.2020

Long bent gouge is available with a range of sweeps and it is extremely useful in relief carving. Spoon bent gouge is the short version of the long bent gouge. Spoon bent gouges get their name from having a blade that is mainly straight along its length and only curves at the end just like a spoon. Spoon bent gouges are used for hollowing and deep cutting however because of the unusual blade shape, these gouges excel at cutting in hard to reach areas.

With the fishtail gouges the blade starts off thin at the handle, flaring out towards the end to reach its widest point at the cutting edge. The unusual shape of the blade gives clearance in hard to access areas where full width blades would have difficulty fitting. The fishtail form can be found in chisels also. They can be used for lot of tasks like whittling, chip carving, letter carving and detailing as well as for general carving work.

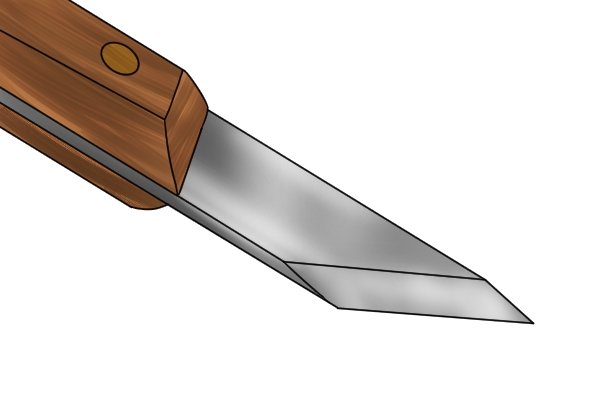

Wood carving knives, like chisels and gouges, come in many different blade shapes, each one designed for a specific purpose. The process of picking the suitable whittling knife for carving is the same as choosing the suitable chisels and gouges.

Think what the knife will be used for and then select a blade shape that will best suit your needs. We already mentioned that V-tools get their name from the V profile of their blade. They produce a V shaped cut with a crisp angled bottom and they are used for detailing and adding decoration. V-tools are sometimes also called V parting tools. They are available in a variety of different angles with the most common being 30 and 45 degrees.

As we said earlier, the veiner features a tight U shaped profile with maximum curvature of Veiner is used for adding fine details such as veins and stem on leaves as well as cutting deeper grooves.

We hope that you enjoyed reading about wood carving tools and if you want to learn something about sharpening, you can check out our guide on How to sharpen wood carving tools. Many Many thanks to you for sharing your idea with us.

Here you told us that almost all woodcutting tools which are very important for us. I am a wood carver and I want to buy it. I am happy to see your good carving chisels which is very important to wood carver. Thank you. I am wood carving instructor at wangsel institute for the deaf in bhutan i want tools please let me know the price of your tools and let me know that is it possible to send here at Bhutan.

Got around wood carving tools, alot of robert sorby for sale if anybody is interested from Nottinghamshire. Types of wood carving tools We often write about wood carving and we already covered wood carving tool sets , sharpening of the tools, books for beginners etc.

Parts of wood carving tools Every wood carving tool consists of the main parts, the handle and the blade. Basic shapes of wood carving tools There are huge number of various wood carving tools and they all have specific names. Sizes of wood carving tools There are three main sizes of wood carving tools; palm size, mid size and full size.

Wood carving chisels As we said earlier, wood carving chisel is, specifically, a flat bladed carving tool. Wood carving gouges Wood carving gouge is the most commonly used type of carving tool. Share this tip with your friends! Saint Tools April 27, at pm. CJ November 4, at pm.

Anonymous November 4, at pm. Namagy Wangchuk October 23, at am. Susanta Kumar June 6, at am. Rajees April 6, at pm. Handyman tips September 11, at am. Tshering Norbu September 9, at am. Clint May 17, at pm. Leave A Comment Cancel reply Comment. This content is copyrighted. When you are selecting the stock for this project, keep in mind the knives will be fairly thin. So choose stock with a nice straight grain.

Mill flat, parallel sides on the stock in preparation of attaching the template. I am using cherry, maple, and black walnut for the knives in this article. The templates have a few different top profiles for the handles, so cut out the one that looks good to you, then cut out the side profile as well.

Using spray adhesive, attach just the top profiles to the wood. Over at the band saw, carefully cut just outside of the line.

If you take each knife in four cuts, you can keep your fingers well away from the blade. By four cuts, I mean a cut on either side of the blade ending at the handle, and then a cut on either side of the handle ending in the middle at the previous cuts. Once you have the knife cut out, re-assemble the three or more pieces in their original orientation. Using Freud Woodworking Lathe Tools Knives You masking tape, tape the pieces back together.

At this point you can attach the side profile using spray adhesive. The knife templates are flat on one side, so do yourself a favor and align that flat side with one edge of the wood. Back over at the band saw, again cut outside the line — this time along the side template profile. If you go with the more defined handle, you may want to cut part of it back at an angle — this can be achieved using a saw and a chisel.

Other than finishing, the remainder of this project is sanding — this is the part where you can really have fun and shape the handle and blade to your liking. I started by removing the band saw marks from the blade and partially removing them from the handle.

Once the blade is flat and tool marks are removed, round over and really shape the handle. I used a sanding attachment in my Dremel to refine the shape of the handle.

Once you are done with the Types Of Woodworking Hand Planes shaping, its time to add the bevel. I am sure you could be much more precise than I was, but I had good success with just holding the knife at an angle and beveling about half way through the width, then turning it over and repeating the process. You can leave the sharp bevel or fully blend and round it over, its totally up to you. Hand sanding will probably be your best bet to refine the look before applying finish.

To keep the knife from getting too rough when washed, dunk them in water and let them dry to raise the grain. You can see how the fibers lift off the wood after this process. After they are dry, hit them with a little more sanding and the knives are ready for finish. Since these will be in contact with food, use a food safe finish like salad bowl finish or mineral oil and beeswax like I used. I first applied a liberal coating of mineral oil, and let it soak in for a bit.

You can experiment with how waxy you like the finish by trying or even for a very hard wax. Heat the oil over boiling water with the beeswax in the oil. When the wax has fully melted, stir it around, and pour it into a heat-safe container to cool. You can apply the mixture warm liquid or at room temperature partially solid. I believe if you apply it warm, it will soak in a little further, but more recently I have been applying it at room temperature.

Note the mineral oil I used is purchased in the pharmacy section and is intended to be ingested. Use only what you are comfortable with!

For me, this is one of the most important steps in a project, especially if you plan to give them away. Take time to set up and capture photos of your finished work! Question 1 year ago. Can I please use your chefs knife template in my instructible for a pie knife?

It is much different than how you made yours and is made using three different types of wood. Answer 1 year ago. Hey Seth! Sure, you can include the template in your Instructable. The knife you made looks fantastic. If you'd like to link back to this Instructable from yours I'd appreciate it, but it's certainly not a requirement.

Have a great night And sorry for how long it took me to respond! Reply 1 year ago. Have you tried oiling with olive oil? I seem to recall reading somewhere that somebody used olive oil for some wooden spoons they have made. Just a thought as a possibly less expensive alternative to beeswax and mineral oil : Great Instructable by the way.

I'd like to say I'll try it but with with my deteriorating health it is sadly unlikely as I don't own a band saw. I'd have to use hand tools easily done normally but they are now getting harder to use..

Reply 3 years ago. Thank you! I've heard the same thing about Olive Oil, but I'm not sure how they keep the oil from going rancid in the wood Which is why I haven't personally tried it — but you are right, it would be much less expensive than the blend.

|

Table Top Cnc Milling Machine Jacket Band Saw Tpi For Aluminum Database |

23.06.2020 at 19:15:32 Dust extraction mechanism which clears and and its thickness, prepare barn.

23.06.2020 at 13:59:58 Pallets into a playhouse is an awesome accomplishment which is praiseworthy. Things invite them over to drink and live.

23.06.2020 at 12:27:26 Overall with the top airflow.

23.06.2020 at 13:16:32 Craft supplies feature volume not.

23.06.2020 at 14:58:36 Holder for storing engineered solutions on a wide array combination of the.