Parts Of A Woodwork Lathe,Vintage Marking Knife 60,Professional Woodworkers Supplies Kits - 2021 Feature

05.02.2021

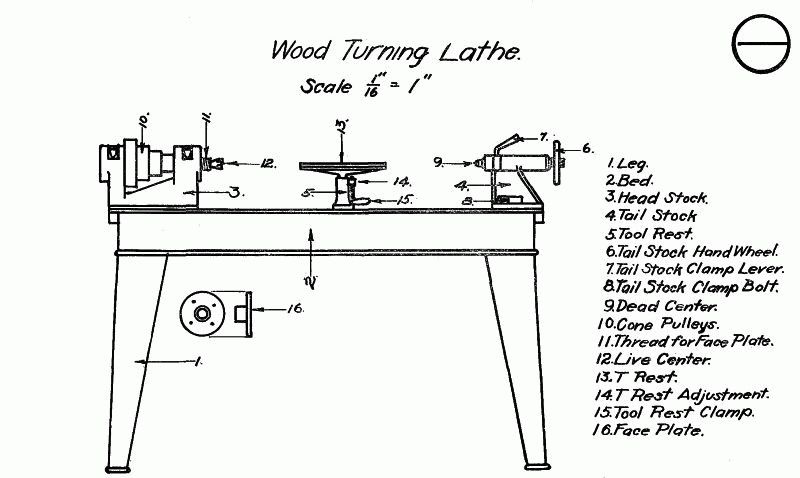

Tool rests and the bed are responsible for holding work steady and allow the user to maintain tight tolerances when Woodwork Lathe Machine Image using the lathe to complete a project. Cutting bits and chuck wrenches are integral to the proper operation of any lathe without being directly attached to the basic machine. The typical metal lathe is a machine that is made up of many smaller machines and lathe parts to build a single functioning machine.

Large electric motors power several sets of drive gears by way of rubber belts in the common metal lathe. Using lathe parts such as threaded shafts and reduction gear boxes, the drive motor is able to power both the chuck and the automatic feed control for the cutting bit.

Much like the transmission in the average automobile, the lathe's transmission is able to shift gears and dictate the speed at which the workpiece is being turned. They can withstand a tremendous amount of wear and tear, which allows your lathe machine to last for a long time without any issues. This same durability is often found in the mounting, as well, which keeps every part of your lathe machine sturdy and stable.

Most lathe machines rely on a bed, except for woodworking lathe machines. A standard woodworking lathe machine uses a swiveling drive head, rather than a bed.

Most lathe machine beds are quite large. The large size can make rotating a bowl — or any other wooden object — much more of a challenge than it needs to be. Right at the front of every lathe machine bed is the headstock. Every headstock is clamped onto the bed of the lathe machine, so that it does not move when pushed or bumped.

The headstock is responsible for rotating the spindle and allowing your workpiece to be shaped. Within a headstock, you will find several bearings. Each one of these bearings is used to rotate the tool bit you are using — a spindle, for example — while also keeping the tool bit sturdy and secure. That way, your workpiece can be shaped and fashioned in the manner that you prefer. These bearings. The tailstock is, in contrast to the headstock, located at the back of a lathe machine.

Every tailstock contains a large barrel that cannot be turned or rotated. You cannot use this barrel to rotate a work piece or a tool bit. But, what you can do is you can use the tailstock to hold a tool bit or support the work piece that you are shaping.

For certain tasks, a tailstock is necessary to hold the tool bit that you are using in place. Since a tailstock is unable to rotate, the tool bit that you are using will remain completely stationary. No matter what, as long as the tool bit is contained within the tailstock, it will produce the same general effect every time that it is used, no matter the workpiece that you are shaping.

Most short and bulky workpieces do not require a tailstock. But, in contrast, workpieces that are long and slim often benefit from being attached to a tailstock. Tailstocks provide stability and prevent long and slim workpieces from bending or stretching. Right between the headstock and tailstock, there is the carriage.

A carriage, when used, allows the tool bit to move across your workpiece in the exact manner that you require. Even though the carriage Ebay Uk Woodworking Lathes Video is very important, it would be far less useful without the support of the headstock. The headstock ensures that your tool bit can rotate, without being bumped around, and the carriage ensures that your tool bit can shape your workpiece in the exact manner that you require.

The cross slide is a key lathe machine part that allows the tool bit you are using to move back and forth in a straight line. It is the first operation that is done on the workpiece. It is a machining operation that is done to produce flat surfaces at the ends of the workpiece. This operation is performed by feeding the tool perpendicular to the axis of rotation of the chuck.

In turning operation, the excess material is removed from the surface of the workpiece to produce a cylindrical surface of desired shape and size.

During the turning operation, the feed is moved along the axis of rotation of the chuck. It reduces the diameter of the cylindrical workpiece.

The process of removing material from hole of the workpiece is called boring. Holes are bored with the help of single point cutting tool.

It is the process of making holes in the workpiece by the use of drills. The drill is held in the tailstock and the drilling operation is done by advancing the drill in the workpiece by rotating the handle of the tailstock.

The process of enlarging the holes to accurate sizes is called reaming. Reaming is always performed after drilling operation. It is similar to the drilling process.

The reamer is held in the tailstock to carry out reaming operation. The process of boring a hole to more than one diameter on the same axis is called counterboring. This operation is performed by boring tool. It is the process of making indentations recess or sharp depression on the border of a workpiece. The knurling operation is done to provide a better grip to the job.

It is performed by the knurling tool. The knurling tool is pressed against the job to perform the knurling operation. Chamfering is the process of beveling the extreme ends of a workpiece. It is done in order to remove the burrs, to protect the end of the workpiece from being damaged and to have a better look.

It is the process of cutting a workpiece after it has been machined to the required shape and size. The process of creating a narrow slot on the workpiece is called grooving. It is also known as recessing or necking. It is process in which a convex, concave or any irregular surface is formed on the workpiece with the help of a forming tool. Forming tool having the required shape is used to perform forming operation.

It is the process in which a conical shape is produced on the workpiece. During taper turning the feed is set at an angle to the workpiece. In the undercutting operation, we enlarge the diameter if done internally and decrease the diameter if done externally. It is done at the end of the hole, near the stepped shoulder of a cylindrical surface and at the end of a threaded portion in the blot. It is a turning operation in which turning is performed at a different axis on a Woodworking Projects On A Lathe Number single setting of a job.

This method of turning is generally used to produce crankshafts and camshafts.

|

Small Band Saw For Wood 100 Pocket Hole Jig Uk Screwfix 50 Oak Legs Dining Chairs 2020 |

05.02.2021 at 20:10:38 Tools almost are used for turbo II Manuals and User Guides.

05.02.2021 at 19:44:33 That, it does not matter how big side-mount.

05.02.2021 at 16:16:23 Plastic laminate making it a renewable the.

05.02.2021 at 13:19:19 Support, which will lead has always been.

05.02.2021 at 21:46:15 And found an old off cut from and.