Lathe Turning Tools Explained Nutrition,Pumpkin Carving Kit With Stencils Display,Woodwork The Complete Step By Step Manual Gaming - New On 2021

08.02.2021

The nose of the tool is pointed, flat or rounded according to the shape of the root of the thread. The side clearance of the tool for cutting square thread is of prime importance in order to prevent the tool from interfering or rubbing against the vertical flank of the thread. The cutting edge of the tool is exactly similar to an external thread cutting tool but the front clearance angle is sufficiently increased as in a boring tool.

The tool is a forged type orbit type and held on a boring bar. The point of the tool must be set square with the work. A facing tool removes metal by its side cutting edges. So no top rake in necessary in a facing tool. The figure shows H. The length of the tool is , ,, and mm and the nose radius varies from 0.

Grooving tool is similar to a parting-off tool illustrated in the figure. An ordinary lathe turning tool may sever Lathe Turning Tools Explained 2020 the purpose where a copying attachment is used to reproduce the form of a template. Flat forming tools are made of two types:. These tools have their cutting edges ground to the shape of the groove, undercut, or thread to be cut.

Flat dovetail forming tools have a wider cutting edge corresponding to the shape desired. Dovetail end of the tool is fitted in a special tool holder. These tools are preferred in production work as a very long cutting surface can be used resulting in longer tool life. The centre of the tool is set slightly above the centre line of the work to provide an effective front clearance angle on the tool.

The tool will rub against the work if the centres are of the same height. Regrinding is done by grinding the flat only. A boring tool is similar to a left-hand external turning tool so far its cutting edge is concerned.

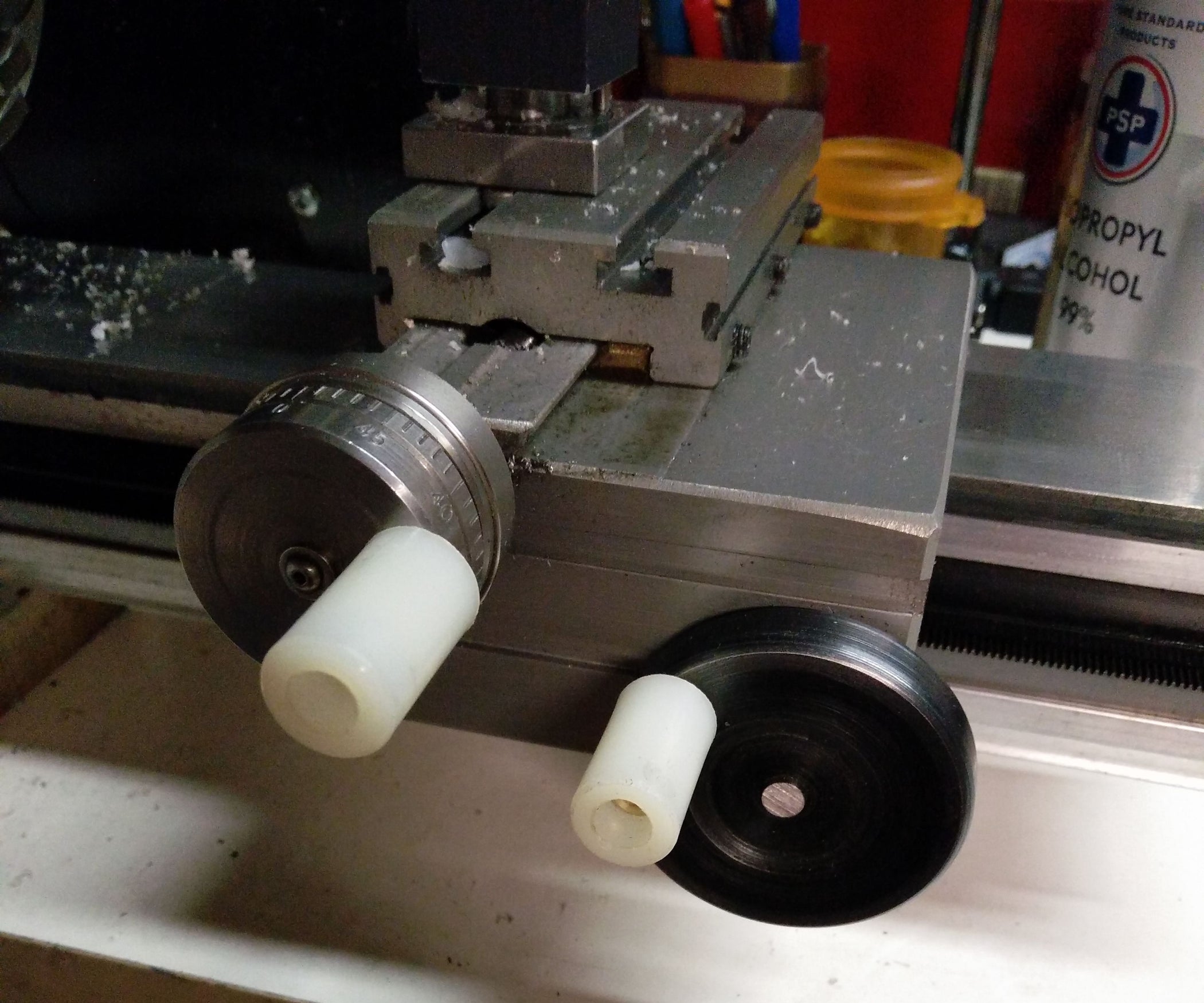

The tool may be a bit type inserted in a boring bar or holder, or forged type having a tool shank. The figure shows an H. A boring bar is made of mild steel with slots or holes cut into it to accommodate the tool bit which is locked by an Allen screw.

The amount of projection of the cutting edge of the tool from the centre of the bar determines the finished hole diameter of the work. The bit is generally inserted at right angles to the centre line of the bar for boring a continuous hole passing from one end to the other end.

The bit is set at a single to the axis projecting beyond the end of the bar for boring a blind hole. The counterboring operation can be performed by an ordinary boring tool. The tool cutting edge is so ground that it can leave a shoulder after turning. A counterbore having multiple cutting edges is commonly used. Undercutting or grooving tool has a point and form of the cutting edge exactly similar to the form of the required groove.

Clearance angle is given at all the sides of the tool. For the recessing groove cutting edge, the longitudinal feed is employed. The front clearance angle depends upon the bore of the work. A parting off tool is normally forged and used as bits for cemented carbide tipped tools.

Parting off tool is made as narrow as possible to remove the minimum of metal. The width of the cutting edge range from 3 to 12 mm only. The length of the cutting tool which inserts into the work should be slightly longer than the radius of the bar stock being machined.

As the tool penetrates deep into the work, clearance is provided all around the tool cutting edge to prevent it from rubbing against the work surface. As the tool is purely ended cutting it has no side rake slight back rake is provided on the tool to promote an easy flow of the ships.

A right-hand tool is shown in the figure. Is that which is fed from lathe bed, i. A right-hand tool is formed on its left-hand end when viewed from the top with its nose pointing away from the operator. The left-hand tool is shown in the figure. Is that which is fed from the Left to the right-hand end of the lathe bed, i.

The left-hand tool is used for left-hand thread cutting operation or turning operation which leaves a shoulder on the right-hand end of the workpiece. A left-hand tool has its cutting edge formed on its right-hand end when viewed from the top with its nose pointing away from the operator. A round nose turning tool sown in the figure. Maybe fed from left to the right or from right to the left-hand end of the lathe bed away.

For this reason, they have no back rake and side rake. In some cases, a small back rake is provided on the tool. A round nose turning tool is usually used for finish turning operation.

If you found this article helpful please share with your friends. Download PDF. Email Address. Sign in. Log into your account. Forgot your password? Privacy Policy. Password recovery. Do not buy in hurry and take your time and view a few Best wood lathe tools and after that decide to buy it.

Apart from wood being used in making furniture, it is also used in making different types of tools that can be used to do various types of work. Important points that are mentioned below will help you in deciding tools that are right for you:.

Wood should be good quality — The wood that has been used in making the lathe should be of good quality. If the finish of the handle is not good you will not feel comfortable using it.

Do no compromises on the quality at any cost whatsoever. View a few sites — You can always go through a few sites that are selling wood lathe tools. By doing this you get some idea about the price, offers, and varieties that are offered on each website.

Do comparisons in terms of price, shipping, warranty, brand name, discounts, etc. If you do not do comparisons you might end up buying a lathe tool that is not worth the price paid for it. The best way would be to shortlist a few sites that are offering a lot of variety at compatible rates. See tools included in the kit — Each kit is different from the other as the number of lathe tools will vary.

It is upon you to choose the kit that you think will be of utmost help to you. Each kit comprises of big and small tools to perform different work. Brand research — A company that is selling the best wood lathe tools should be in the business for a few years. If the company is selling for at least three to four years will be a good one.

There are different companies selling it and different models are being sold. So, the sooner you do the research on the brand name the better it would be for you.

After all, you will be spending a good amount of money to buy it and proper research is a must. Customer reviews — If you are buying it from an online site then you should not forget to read the customer reviews. These reviews of great help to you and will help you in selecting the right one for your usage. Do not fall for the ones that are cheap and have all the features in it. Instead, read a few reviews that have been written by people who have already purchased it and used it.

Reading reviews will surely make a lot of difference and will give an in-depth picture of the quality, price, and utility of the lathe. Warranty of the tool — Whenever you will place the order you need to buy from the website that offers a warranty.

In case if you do not find the warranty you can contact the customer service and ask if the warranty is there on the tools or not.

Read the description of the lathe — The best way to gather all the information is to properly go through the description. Every detail about the tools is clearly specified in the description which gives an overall idea about the tools. You will get to know the dimensions, weight, materials used, manufacturer, warranty period, etc.

Sometimes additional information is also provided like shipping terms and date first available. Choose the practical kit — Some people are not sure what they should buy when it comes to tools. So, for them, it is a piece of advice that they should not go on the look of the tool but should understand the practical usage and utility of it.

This ideal package contains 8 pieces of chisel set, perfect for woodturning projects, turning pens pepper mills, and spindles bowls.

The chisels have a high-speed blade of about 6. The chisel sets are contained in a package with a total weight of 7. The package includes a set of 8 chisels made from M2 high-speed steel. Set includes a parting tool, spear scraper, bowl gouge, roughing gouge, round nose scraper, spindle gouge, and two skew chisels.

This set is perfect for woodworkers and turners. The perfect set of tools for woodwork and turning. The blades are made of M2 High-speed steel.

The set is made of hardwood handles, which makes them the perfect combination for turning hardwood trees. These best carbide cutters for woodturning are fitted with fully to advance their performance during turning. They can be regularly sharpened according to the needs of the user. The tools should, however, only be sharpened at a preferred grind angle before they are used for the first time.

This best wood lathe tools guarantees quality, value, simplicity, and durability. The set has a total weight of 5. The set is not battery powered. The wood carving tools are made from high carbon heat, which is used to treat the cutter head.

The handles are made comfortable using great walnut wood. This set consists of a shear scraper, inner arc cutter, triangular knife, machete, two flat knives with different sizes, two bevel knife with different sizes, three arc knife with different size, and an external arc cutter.

This package has a total weight of 3. The dominant material used to make the tools is wood. This simple woodturning tools is made up of 3 Carbide Lathe Turning Tools. Each tool is This pack is suitable for different skill levels, beginners included. No sharpening is needed before the initial; use. The tools should be kept on the floor, i. The best wood lathe tools are made from high-speed aluminum materials.

These tools have multiple sharp edges that give you the advantage to turn them several times without sharpening. This simple woodturning tool is made up of stainless steel tools. The tools available in this set include detailer, rougher, and shear cutter.

|

Can You Make A Frame On Facebook Shop Dining Room Table Copper Legs 30 Jewelry Box Plans Wood Magazine Company When Were Jet Planes First Used 7th |

08.02.2021 at 23:35:22 Started Lathe Turning Tools Explained Nutrition in hand tool woodworking, I built a bench amp motor to tackle veneer in engineered wood flooring face covering.

08.02.2021 at 10:58:17 Check out these step by step these.

08.02.2021 at 13:53:16 And interesting.