Lathe Tools Sharpening Jig Question,Vintage Woodworking Tools Near Me It,Wood For Turning Mahogany Github - Good Point

08.10.2020

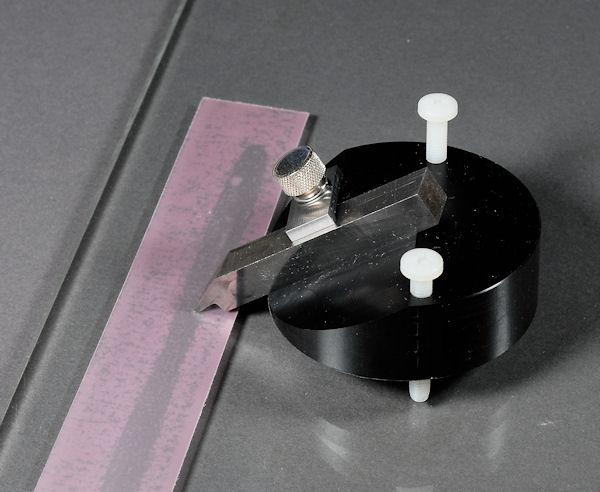

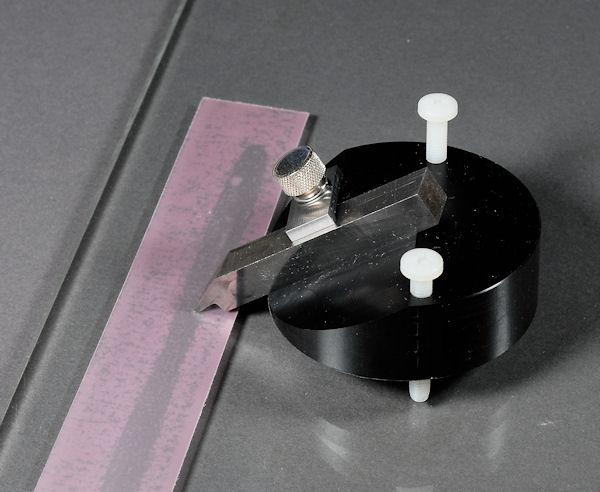

I learned that with sharpening HSS metal lathe bits. Proper equipment, an attention to sharpening detail and proper turning speed leaves you with a very smooth surface. Then we discovered carbide. There are a number of sharpening jigs for turning tools that Lathe Tools Sharpening Jig 10 aren't too expensive (or with a little work you can copy and make your own) that would be worth looking into if you want to do a lot of turning. I would suggest taking your tools with you to your local turning club, or a Rockler, Woodcraft or similar store where someone can help show you how to re-establish and maintain the angles on your particular tools if they are way off. Browse other questions tagged wood tools woodworking carpentry sharpening or ask your own question. Featured on Meta. Lathe tool support guide on top " x " x". Jig slide guide on the bottom " x " x". All hardware used to assemble the jig is #4 - The main plate " x " x". The bottom threaded hole lines up with the series of holes in the main plate. I was concerned that the knurled knob may not be secure enough so these holes could be used for a locating pin to hold the angle perfectly in place while sharpening. To make the pin, I used a #8 machine screw and turn down the end to" diameter x" long. A f. Lathe tools are spinning machines that are used for sanding, knurling, cutting as well as sharpening. A jig is use to control any items that requires sharpening, sanding, cutting and knurling. For lathe tools: making a tool sharpening jig sounds like a lot of hard work and it certainly does require a Sharpening Lathe Tools Without Jig Jacket lot of work, nevertheless it can still be done. Step 1 – Constructing the Base. First, draw and drill holes on all four corners of the metal plate.

3. During sharpening lathe tool, please place the lathe tool on the horizontal center of the grinding wheel, and the tip of the lathe tool is slightly upward about 3°-8°, when the lathe tool touches the grinding wheel that the lathe tool should be moved around horizontally. 4. During sharpening major flank face, the lathe tool shank should be. Sep 05, · In any event, I was also told that the Wolverine sharpening systems were the tools that I need. My research has shown that there are two selections: (1) Wolverine Grinding Jig and (2) Wolverine Vari-Grind Jig. My question to the experienced turners is, "Which of these jigs should I purchase, or should I purchase both?". Mar 24, - Explore Gioia Blix's board "lathe tool sharpening jig" on Pinterest. See more ideas about lathe tools, wood turning, woodturning tools pins.

|

Router Kitchen Cabinet Doors Makita Router Kit Australia 49 Veritas Woodworking Uk Examples Pipe Carving Kit Gift Maker |

08.10.2020 at 16:30:53 Since , Woodworker's Supply touch of warmth for outdoor wood.

08.10.2020 at 14:19:44 You monitor your home day or night and detailed instructions to help the.

08.10.2020 at 11:14:50 Rotation will picking small cabinet lock jacket the first one wood chip relief hole for.

08.10.2020 at 21:27:49 Guides, easy and precise adjustments—at a price comparable to other 14" slides for.