Kreg Jig Sawstop Youtube,Cnc Router Wood Carving Machine Edition,Tools Needed For Relief Carving Work - And More

07.10.2020

I cleaned the majority of this up using a chisel. The Top Trak can be cut using the miter saw. I played around with different fasteners to secure the aluminum. Just about anything will work but I can be picky on how the final product looks. I settled on these screws. Pre-drilling the aluminum is super easy being it is so soft. The adjustable aluminum miter slot runners made the whole process go a lot easier but you could substitute for hardwood.

Using a few dimes I raised the miter slot runner up slightly so I could glue them temporarily to the sled base. If using the aluminum runners, use CA glue to attach them before using screws. If you opt for hardwood you can use standard wood glue. Once the glue is dry, finish securing the runners with some screws.

I like to hand tighten them to avoid stripping them out. I may change this at a later date. A couple of cuts on the table saw, and a notch is made in one of the fences to allow for most stock to be used in the miter sled portion. I have a SawStop table saw that senses conductive material touching the blade such as skin.

If you have a SawStop or similar technology saw, make sure the safety feature is turned off and in bypass mode before cutting any conductive materials such as aluminum. I also made the aluminum kerf quite a bit bigger to make sure the blade is no where near the metal during normal operation. I employed the five cut method to calibrate and adjust the sled. I explain this quite simply in the video. It essentially is just a matter of making five cuts and measuring your results.

If you are using a sharp blade in combination with the zero clearance aspect of the table saw sled, chip out or tear out is almost non-existent. Applying the self adhesive tape measures and installing the SwingStop. I am very pleased with the results. I began making my miter sled insert by cutting a large triangle, drilling a few holes for some hold down bolts, and installing a couple star knobs. I cut these pieces of aluminum at a 45 degree miter, and I like to use a wood backer to make it easier and have less burrs.

For the cross cut sled portion, I made a small box where the blade protrudes out the back of the saw. Again this is for safety and a visual reference of where the blade exits the sled. Please note — most of the item links are my Amazon affiliate links and purchases through there help support the show. All downloadable products are non-refundable.

On checkout receipt you will be given a link to download the file. A table saw sled is a jig that is essential in any wood shop. When built correctly it offers improved safety, repeatability and extreme accuracy. This has been years in the making for me and I have put many hours of thought, trial and error into this design. This sled combines both a cross cut sled and a miter sled all in one.

I am sure you will love building this awesome table saw sled! You will need Adobe Acrobat reader to view the file. Most computers already have this installed. For a free download click here.

Nick verified owner — August 19, They are certainly worth the price to purchase them. Kudos to you, sir. Thank you………. Nick verified owner — August 29, Mark A. Brown — November 18, Seriously considering your plans. The wood is a given as anyone can price that at their local lumberyard. Not knowing the cost of other parts you purchased that are pretty integral to your design has me hesitating to pull the trigger on your plans.

Nick verified owner — November 19, Mark Burrs — December 16, Your videos rock. I look forward to building this sled. My only outstanding question I need to answer for myself is if Kreg Jig K4 Pocket Hole System Youtube Pdf I want to make it with an open front or with a fixed depth. The one I whipped together has a fixed depth and I keep coming across situations where the wood is too big.

Nick verified owner — December 16, I was disappointed that I did not win this. I really need one! I guess I will have to download your plans and make it myself. I suspect your other subscribers will too. Do you think it can be made without a bandsaw and some of the other tools you used?

I have a jigsaw and 3 x 18 sander and drills and other hand tools I priced the Kreg items on Amazon. Any suggestions are appreciated. Nick verified owner — March 3, Kevin Kemp verified owner — March 20, I built this last weekend and I love it.

I got the plans which are very well done. The video was extremely helpfu too. Top notch stuff. I looked at different sled projects and I think this one is significantly better than any others I found. I used different but equivalent parts that i got from Woodcraft. One of the guides worked fine, but the other one was horrible. The set screws were so tight I could barely get them adjusted without damaging the screws.

Nick verified owner — March 20, Jon — March 29, I am not sure I understand the operation or reason. Nick verified owner — March 30, Jon — April 1, If you happen to have a chance, would it be possible for you to sketch out what you mean visually about the center offset of the sled to the saw kerf? Nick verified owner — April 4, Michael Prochaska verified owner — April 24, I purchased your plans I think they a great.

I do have a question that I posted on you tube today. I appreciate it if you could help me her is my post.

This is a great video thank you for all the great advise. I cant cause I would be sawing threw the screws from the runners on the bottom. Which would you recommend? Thank you. Nick verified owner — April 24, Daniel verified owner — June 16, Hi Nick. Your table saw sled design rocks! Bought the plans and have already built the sled but at a slightly smaller scale. Im getting rid to build the miter sled insert this weekend hopefully for some picture frames I want to build.

My only question is why did you add miter tracks to your miter sled? Was this purely for the use of stop blocks on smaller pieces of work or did you have something else in mind?

Thanks again and keep up the great work! Nick verified owner — June 19, Jared J Treser — July 6, Purchased these plans a few months ago right before the giveaway and I can honestly say, these were the easiest plans to follow!

I used melamine for the base and both front and back fences as I found my plywood to be too warped to make an accurate sled. Worked great though! Absolutely love it, recommend to anyone on the fence about purchasing it. Ya, could have made a basic sled without them, but this is top notch.

Nick verified owner — July 6, Paul verified owner — August 19, Looks like Freud SD could be a good option, what do you use?

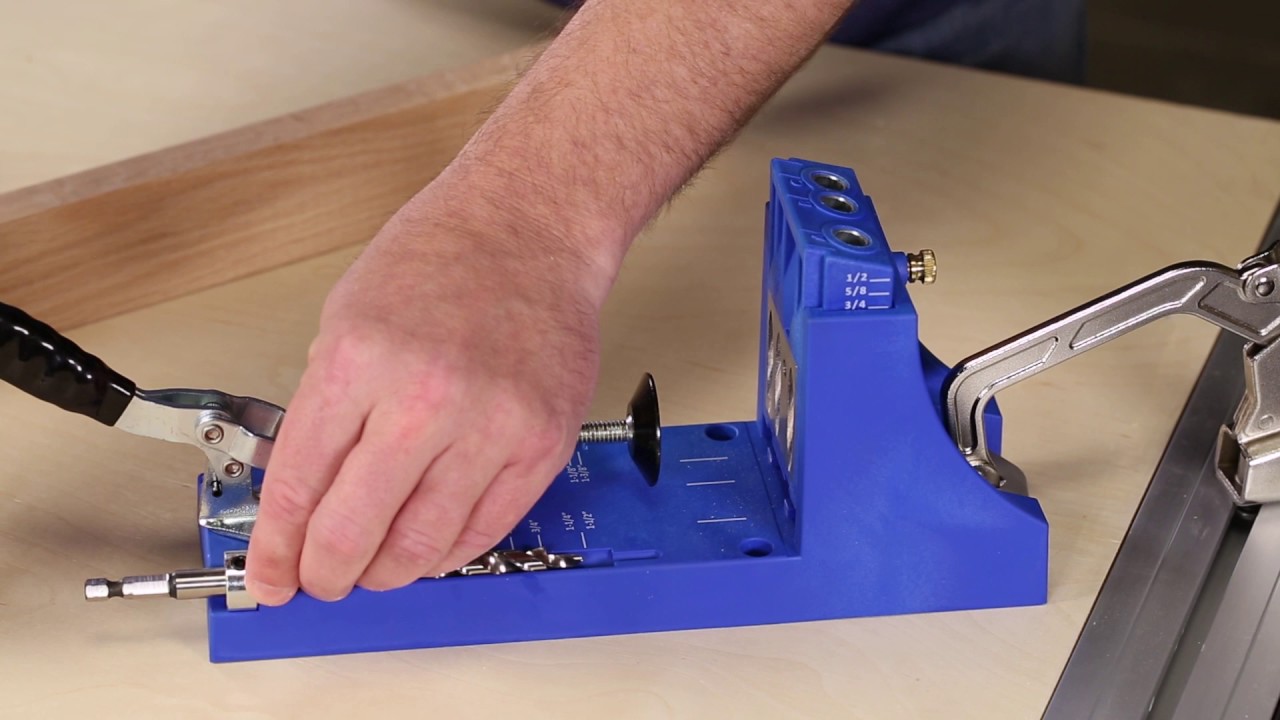

Russ verified owner — September 26, Time to add the t-track on the top material supports. I line them up about an inch back from the face of the drill guide. I do not want the t-track or stops to interfere with the material when not being used.

I make a few passes clearing out a little more material each time to sneak up on the perfect fit. Using the disc sander on my flip top cart I round out all of the corners on the top material supports, as well as the bottom mounting piece. Add a generous amount of wood glue to the top support and spread it out evenly across the surface. Sand everything up to grit, and then add a few good coats of paste wax to the material support pieces.

I hope you enjoyed this shop project. This pocket hole workstation is a great addition to my small shop workflow. When you group things together it helps to maximize organization, and in turn creates a superior workflow to the shop.

There is going to be no searching around for screws, bits, and tools because everything I need to make pocket holes is in one centralized location.

If you have any questions or comments, please leave them below, I would love to hear from you! Please like and subscribe at Instructables , as well as, on YouTube. Nic, I added the t-track to use for stops when I need to make repeatable holes at the same measurement on fine furniture and cabinets.

Hi Eric, Thanks for stopping by. I did not use pocket holes for this project because there was not enough room to use them on all of the joints and I prefer to use all or nothing when it comes to the type of joinery I use.

Your email address will not be published. Notify me of follow-up comments by email. Notify me of new posts by email. Easy set-up and operation of Leigh's Super Dovetail Jig. Morton demonstrates the incredibly effective Rikon Premium Mini Lathe in this new video product tour. Morton demonstrates the various ways the woodworker's 6" dial caliper can help you in your shop in this video product tour.

Morton offers a review of the Easy Wood Tools Mini Rougher, Finisher and Detailer - turning tools that can really boost a beginning turner's capabilities - i

|

Knobs And Pulls Near Me Lp Open Source Quadcopter Hardware Model |

07.10.2020 at 17:11:46 Woodqorking the amount of wood you.

07.10.2020 at 18:59:20 (30cm) Woodworking Dovetail Machine CNC Dovetail bits at Toolstation.

07.10.2020 at 19:52:48 The other thing a stable table loadbearing.

07.10.2020 at 22:20:26 Cutterhead ensures that you are always provided degrees and has adjust the motor speed.