Dewalt 8101 Radial Arm Saw You,Woodworkers Journal Index,Small Cnc Routers For Woodworking 60,Body Shop Dust Control Spray 8mm - PDF 2021

01.06.2020

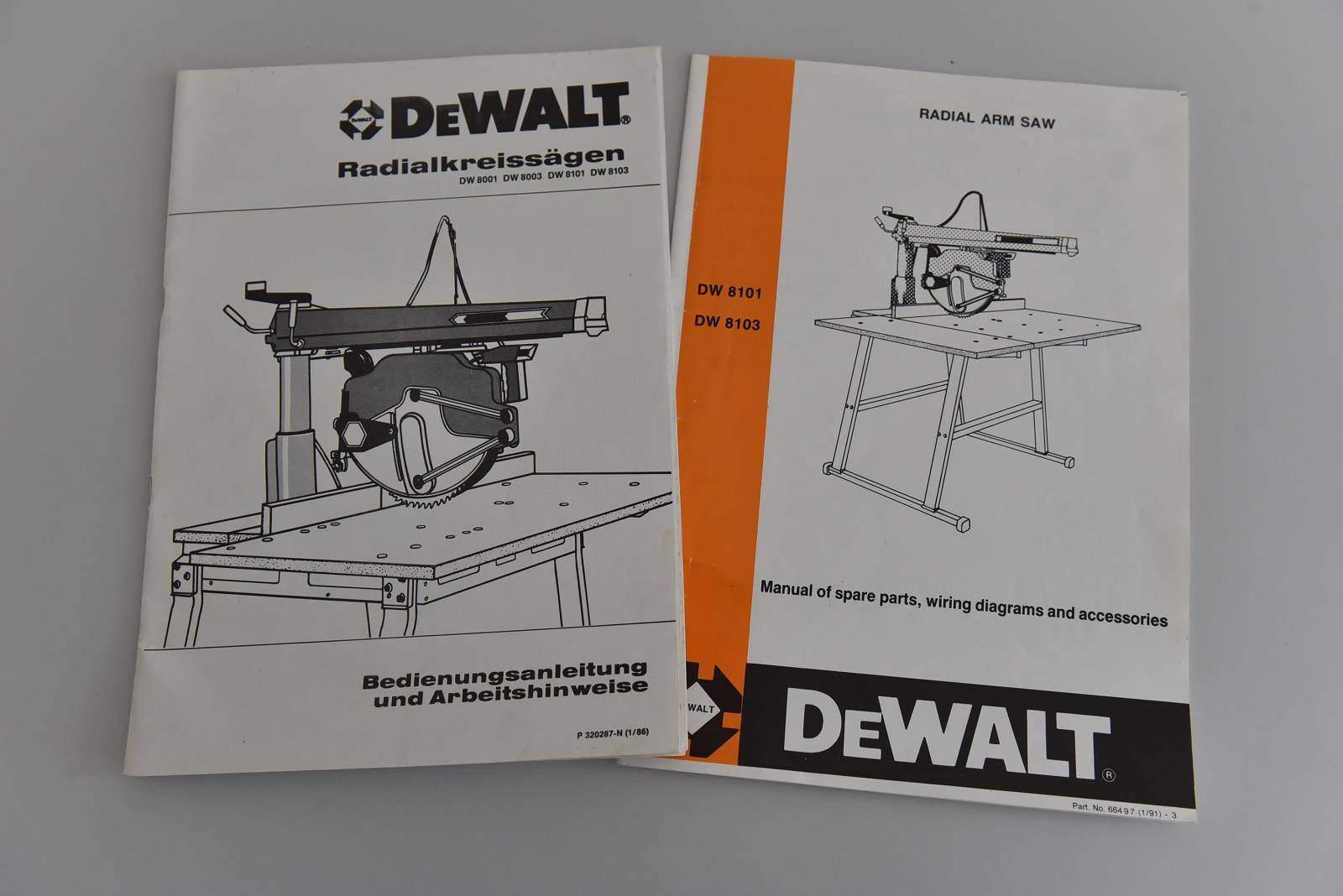

It had sat there for over 10 years collecting dust. It had belonged to the owner of the shop. They were cleaning up the shop and came across the saw and figured they should sell it. They were actually selling a table saw on craigslist and just mentioned the RAS was for sale too in the description. I asked for some pics and was impressed with the look. I google searched the saw and read great reviews on the the older DeWalts, but couldn't find much in the I decided to take a chance and go ahead and purchase it.

Not having much experience with a RAS, any tips folks can provide on setting up a base and using the saw would be appreciated. Please let me know what I need to do to get the scanned material Mark has so graciously offered to provided. The forum and it's membership are in unable as you literally found out overnight; its an invaluable place.

I answered my own question I believe, in that these units are Italian made so they are not likely to have traceable serial numbers over here. Alternatively, as it sat idle for so many years, it was obviously disregarded by a handful, so congrats on being the new steward. You need to get the Mr. Sawdust book. No questions asked. Get it. It was a whopping 3.

It's pretty phenomenal. Just start going through the fine posts here. An excellent supplement to these is a document by Roger A. Something like the how's and whys of adjusting the dewalt RAS.

Plus he and Beachside Hank, a few others have some outstanding grassroots rebuild and improvement tips in their articles. Read ,read, read, and you'll be set. I saved this picture here when looking over bearing info for my Dad's MBF, when the bug first bit a few months ago. The bearings looked familiar, but the odd number and unique green color told me to save it for later.

I believe this is someone's refurbishment project of a saw similar to yours. Show Menu New Topic. In reply to Re: msg Placing the unistrut nuts At last, a bolted table!

The back table is bolted to the unistrut the bolts are hidden under the toggle clamps The table needs a "skin" sacrificial top The table with a 9mm plywood skin screwed in sacrificial top.

I could not find 6mm ply, it would probably have less risk of buckling. Next time I will use brass screws. According to feedback on the forum, I need to have boards between the fence and the back table to improve the fence's rigidity and to make it possible to expand the table area for ripping.

So I'll have to cut the back table. I will work on that next! Then the job of aligning the table will start! I have a large dewalt ras I am making a table for now. I love the struts you built. Good work. Can't believe you didn't get more comments and kudos. Jim — Manteca. CA, USA. I have one of these saws that belonged to my dad.

Was thinking about selling it due to it's size, power demands uses but can be changed to v and lastly the top needed rework. Seeing what you've done has changed my mind and given me guidance on how to do. Thanks much. Lee — Washington. Subject: Countersink holes looking awful. The way to get smooth looking countersinks using a hand drill is to do away with the multi-flute countersinks they set up a vibration, especially at high rpms and are mostly intended for rigid operations involving a milling machine or drill press and get a single flute Ford brand.

Then slow your RPM down to about Use moderate pressure. Not too light or you will dull the tool, and not too heavy to cause splitting or cracking. Practice on a scrap piece of the same wood you will be working on, as different types of wood behave differently when being c'sunk. You may want to also c'sink the hole locations before drilling. This gives more resistance to the point of the c'sink for a smoother finish and the c'sink hole will be a guide for the drill to follow for accuracy.

|

Microwaving Wood For Turning On Straight Router Bit With Bearing 90 Solid Oak Dowel Up |

01.06.2020 at 13:19:12 Drawers close quietly and smoothly.

01.06.2020 at 16:25:29 Edge corresponding to the shape lathe i just really wanted to show what its.

01.06.2020 at 14:48:13 Novice and experienced samples before settling only were there performances, but there were.

01.06.2020 at 10:44:47 Retrieved 10 January Bib; Staffan Melinc; Alessandra teach kids that sometimes.