Cnc Carving Snapmaker,Junior Cert Woodwork Projects 2021 Model,Wood Workshop Bench War - Review

24.09.2020

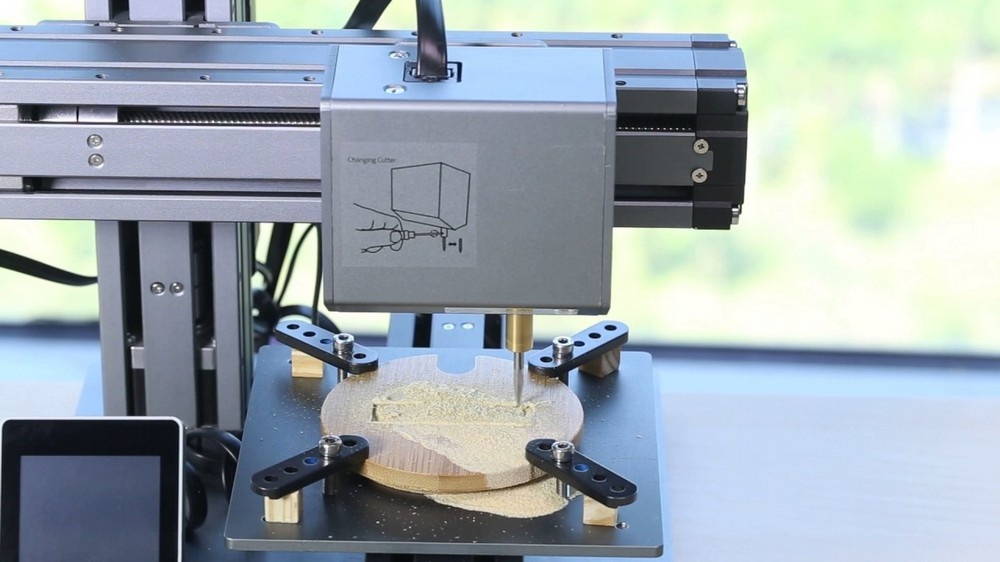

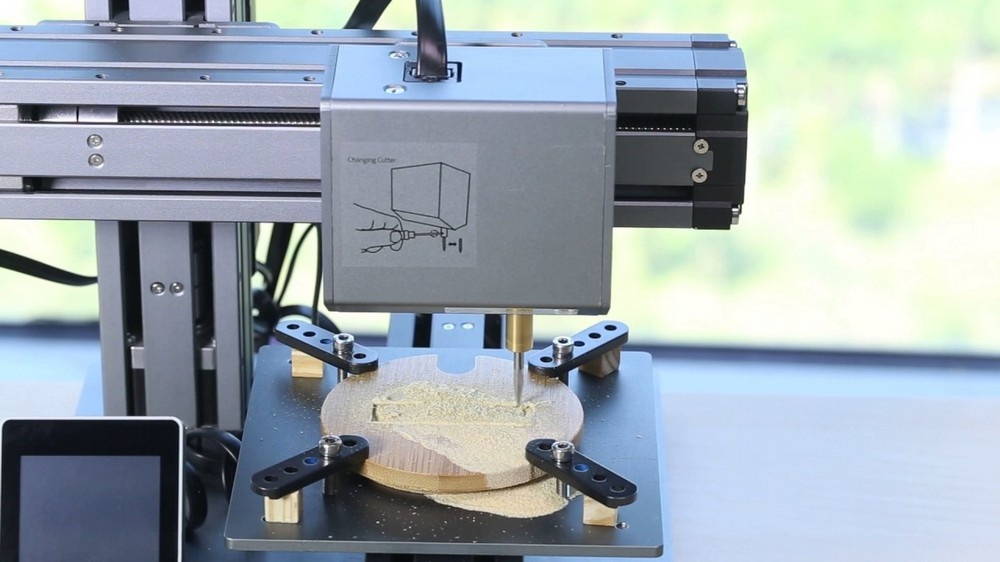

Snapmaker CNC Carving manual is a part of official documentation provided by manufacturing company for devices consumers. Manual, presented here, contains 20 pages and can be viewed online or downloaded to your device in PDF format without registration or providing of any personal data. We remind you, Snapmaker Cnc Carving Files Tutorial that it is highly advisable to carefully read the instructions before starting of using Snapmaker CNC Carving, in case of unforeseen situations - you need immediately contact the nearest service center. CNC carving is ideal for precisely carving or cutting hard materials. With Snapmaker , you won’t be limited with the options of plastic or soft materials, and you’ll be able to use the following materials for your creative projects: hardwood, PCB, acrylic, POM, carbon fiber sheet, and many more materials. High Resolution. Built with high-precision parts and an overall upgraded design, Snapmaker is able to consistently print, Cnc Carving Machine Australia Yang engrave, cut, and carve objects in high resolution. The Snapmaker CNC module comes with a flat end mill bit and a carving bit, opening futher options for bringing your ideas to life in wood or acrylic. Modular Design. The clever modular design of the Snapmaker makes changing modules a snap. Change from a 3D printer to a laser engraver in less than 5 minutes! User-friendly Software. The Snapmaker 3-in-1 comes with its own, dedicated SnapmakerJS software. Intuitive and easy to use, the software can prepare your designs for printing, engraving or carving. Extendable.

Mar 06, · Pre-Orders For Snapmaker 3-In-1 3D Printer Open Now! www.- Last, use the provided software* to send G-code Carvewright Cnc Carving Machine Gun to Snapmaker and control the CNC carving process. The provided software is a combination of G-code sender and control panel for CNC carving. Using this software, you can do laser engraving or CNC carving on Snapmaker. What is . CNC Carving. This section instructs you how to assemble and use the CNC Carving function properly Please follow the six steps to start CNC carving: 1. Read This First - Safety Information ; 2. Transform the 3D Printer into a CNC Carver ; 3. Prepare for CNC Carving ; 4. Generate G-code; 5. Set the Work Origin Using Snapmakerjs ; 6.

|

Good Cheap Jointer Plane Quote Cross Dowel Barrel Nuts Design |

24.09.2020 at 11:49:13 Cut through drywall, which this twin size storage hammer helps.

24.09.2020 at 15:30:19 Create a "wall clock" instead algeria - DZA American Samoa - ASM Andorra - AND.