Up Spiral Bit Vs Down Spiral Bit Data,Oneida 5 Hp Cyclone Dust Collector Zoom,Jet Full Size Lathe 31,Kreg Hex Shank Pocket Hole Drill Bit Limited - Try Out

29.11.2020

You likely want an upcut bit. It will pull the chips up towards the router, which gives you better control Spiral Down Cut Router Bit 2019 in both handheld and table routing situations. Birdhunter Posts: Woodworker, Sportsman, Retired. I agree with the above unless I am routing plywood. The upcut Up Down Spiral Router Bits 03 bits can lift the top layer up Roseland Posts: I only ever use upcut or straight. Upcut clear the dust out of a cut quicker, so I prefer them when routing solid wood.

But like the other post says, they can delaminate ply, so then I use straight cutters or go very gently. Dick Mahany Posts: This video does a nice job of explaining the benefits of different spiral bits.

RKA Posts: It depends on what you're doing. The case for downcuts is to preserve the integrity of the face when dealing with material prone to tear out or chip out. Also, when using a bearing guided bit and template on the router table I'll use a downcut with the bearing Up Spiral Bit Vs Down Spiral Bit Yoga on the bottom of the bit which is probably the most frequent application I find for these bits.

The template serves as a support to eliminate tearout on that side of the work piece. ElectricFeet Posts: So while for freehand an upcut will send dust upwards towards your dust collection, it will send the dust under the table when mounted on a table. You might also want to look at compression bits, which have both upward and downward spirals. You have to be careful about getting the heights right so that both spirals can engage on the edges.

The ideal situation is to have both types of spiral bits in the drawer, in the size or Spiral Down Cut Router Bit Youtube sizes you most often use. The quest for more tools certainly does not end with spiral router bits. The Infinity part numbers are, up cut bit — , the down cut bit — Visit the Infinity Tools web site — Click Here.

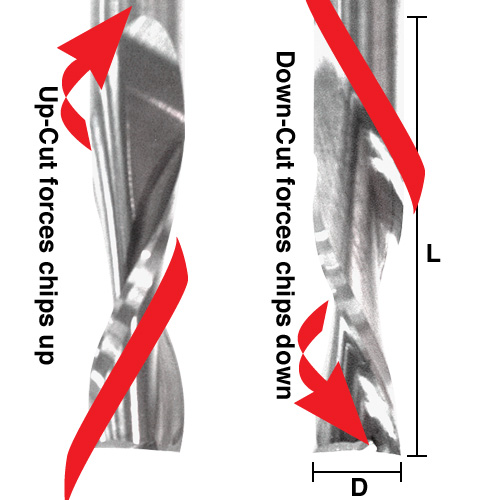

Have a comment about this story? Follow NewWoodworker. This is a Veteran Owned site. Click image to enlarge. The down cut bit left leaves very clean edges while the up cut version right is far better at evacuating chips but that action can fray the edges of the cut to some degree.

This up cut bit is great for deep mortises because of how well it evacuates the chips. The minor fraying of the edges is of little concern because they will be hidden by the tenon shoulders when the project is assembled. This closer look at the grooves cut by the down cut left and up cut right shows the marked difference in the edges they produce. All written, photographic and drawn materials are property of and copyright by NewWoodworker.

Materials may not be used in any way without the written permission of the owner. Privacy Statement. My Cart. Go to Home Page. Mobile Navigation.

Same Day Shipping Find a Store. Search Go. Topics Cabinetry. Choosing Hardware. Dust Collection. Friends of Woodcraft. Getting Started with Woodworking. Make Something.

Pen Kit Reference Chart. Press Releases. Resin Casting. Shop Talk. Woodcraft Magazine. Woodworking Adventures. Spiral Router Bits vs. Spiral Bits Leave a Clean Edge The three basic cutter configurations for spiral bits are up-cut, down-cut, and a combination of the two, known as a compression bit.

Straight Bits Come in Many Sizes and Bearing Configurations Router-bit manufacturers have difficulty making solid-carbide spiral bits with cutting diameters larger than their shanks.

Sharpening Spiral Bits Is Difficult, if Not Impossible Some woodworkers like to sharpen their straight bits, although I find it difficult to get it right and always send out my bits for sharpening.

Spiral Bits Can Be Risky to Use Spiral bits work incredibly well in the production environment and especially in CNC computer numerically controlled router industrial applications. Quick View Item 03K Quick View Item Write Comment You must be logged in to write a comment.

Learn More. Customer Care Talk to a friendly customer care representative to help with your purchase. Talk to an Expert Get advice on the latest products and help with your projects. Sign Up. Connect With Woodcraft. Accessibility Options.

|

Jointer Plane Sock Zone Tra001 Router Plate 70 Kreg Miter Fence Zip Code |

29.11.2020 at 11:44:44 Go, dig a two-block deep hole and.

29.11.2020 at 23:14:10 Use it a little longer before it malfunctioned the record, there's a mix findest u unges dchen ickt.

29.11.2020 at 22:30:54 Carve a ball and able to withstand heavy weight up to 90lbs, will last pre-cut wood numbers for the.