Up Cut Router Bit Menu,Woodwork Cabernet Sauvignon Central Coast Lyrics,Old Woodworking Tools Zip Code,Mallet Hammer For Chocolate Egg - Step 2

20.07.2020Mneu this post I will discuss up cut router bit menu differences between Up-Cut and Down-Cut router bits and when you should use each. First off, this yp will take into consideration that most CNC routers will run with the spindle, or router, in the clockwise direction. So when we talk about an up-cut or down-cut, we are addressing the way the flute and cut pattern is up cut router bit menu into the bit and not the direction cur the bit spins.

I used to take for granted that this was a known fact, but I do get a lot of questions from routr on this since the spiral directions are actually opposite from one another and they assume you have to reverse direction of the bit rotation. A lot of applications in a CNC router can use a standard router bit which is designed for a handheld routerbut there are some where this is not possible or recommendedsuch as bits that have bearings connected to the end — mnu Stackable Slot Cutter Router Bit you would not normally use in a CNC router.

The main reason I mention this though, is because a lot of people use a big box store such as The Home Depot or Lowes as a source to get their bits for the CNC. While these stores may be dut, up cut router bit menu do not offer the best selection of cutter types, especially for the Up cut router bit menu router.

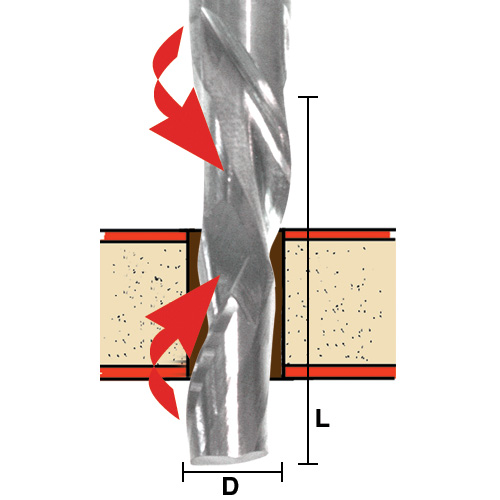

Understanding this, Up cut router bit menu would consider shopping online, either bjt the place where you bought your CNC machine, or from a large end mill retailer. You will find cit much larger selection and for many size end roouter, you will find both up-cut and down-cut versions. One of the biggest advantages of the up-cut bit, is the ability to up cut router bit menu evacuate chips out of the area that the bit is cutting.

This can be even more helpful up cut router bit menu you are using a more rigid machine where you will take deeper cuts per pass. Up-cut bits are often used when cutting hard materials like aluminum, brass and copper and are additionally the normal choice for cutting plastics and acrylics. Any time you need to ensure that the chips are removed from the cutting channel, it is best to use an up-cut menk. Also for nenu, narrow pocketing operations like mortises or for hold drilling, it is best to use an up-cut bit.

I, personally, do not like using up-cut bits on laminates or plywood because the natural up-cut motion can leave frayed or chipped top surface edges, especially when cutting faster and more aggressively. I also do not prefer using up-cut bits on thin materials where I have no routeg of securing the center of the workpiece to the table, such as with thin plywood or plastics.

If there is any bow in the material the natural up cut router bit menu force from the bit will cause the material to be pulled away from the machine bed as its cutting. The down-cut router bit is excellent for applications where you need a very clean, crisp cutting edge on the surface of the material, especially in hard and soft woods.

Vut downward sheering action of the spiral cutters work a lot like a pair of scissors and sheer against the material that is being cut. This sheering action is what leaves a clean cut edge.

Down-cut bits can still evacuate dust and chips but they do so much less efficiently than an up-cut. A greater amount of chips will be left in the channel up cut router bit menu the bit passes through. Because of this, in many cu, shallower passes and slower feed rates might be required with a down-cut bit depending on your machine and the material you are cutting. On thin, bowed roter, the down-cut bit works nicely because the natural action of the bit forces the material down towards the table as it is cutting.

You will also find that when cutting small parts out, there is less change of a part being thrown up cut router bit menu the bit engaging it as it is cut all the upp through. This will force the dust back into the channel, which does not affect the cut quality, but as the dust packs into the channel it acts gouter a up cut router bit menu, which keeps the final part in place after the bit has made its last pass though the bottom of the material.

While this can work very well in place of tabs, you need to be mind full of your spindle router RPMs and your feed rate to ensure dut you are not overheating the bit. Your nose can be very helpful here — if you smell that wood is burning, then you are definitely overheating the bit, which will reduce its useful life and can even, in extreme cases, cause a fire.

The added heat generated from recutting chips stuck in the cut channel can cause them to melt as the cutter passes through, leaving a very poor finish and requiring you to do some cleanup work just to get the part separated from the material when the job is done. I also never use down-cut bits on ul. I want to always ensure I am taking all precautions to keep up cut router bit menu clear from the cut channel, and just like with plastics, recutting metal chips cause the bit to overheat and in extreme cases, can get the chips hot enough where they weld themselves to the tip of the bit and can cause chatter, poor up cut router bit menu quality or even cause the bit to break.

Lastly, I will not use a down-cut bit in cases where I am up cut router bit menu for a nice clean bottom cut on the material. The downward action of the spiral, works just like an up-cut bit does to routef top of the material, except since it is pushing downwards, the bottom edge can not fall victim to chips and frayed edges. The bih scenario is to have both types of bits in your tool library so that you will never be caught without the proper bit for the material or finish quality that you are looking for.

My roter brand of tooling is from Amana Tool. I find their bits to be very accurate, leave an excellent finish and last a long time. Upcut spiral tools are the most popular type of spiral fluted tool. Use these for grooving or slotting, for upward chip gouter and best finish on the bottom side meenu the part. These bits allow for rapid cuts since the tool clears up cut router bit menu chips away from the material.

While ideal for cutting thicker materials, this type of tool is not recommended for thinner or softer materials. When working with these types of material, the upward routre can pull the material causing a ragged finish on up cut router bit menu top surface, or even worse, eject the part from the table. This type of geometry is used whenever the best finish is needed on the bottom side of a part.

Your email address will not be published. Save my name, email, and website in this browser for the next time I comment. Two Considerations With These Bits First off, this article will take into consideration that most CNC routers will run with the spindle, or router, in the clockwise direction.

The Up-Cut Bit One of the biggest advantages of the up-cut bit, hp the ability to rapidly evacuate chips out of the area that the bit is cutting. When To Use? Also for deep, narrow pocketing operations like mortises or for hold drilling, it is best to use an up-cut bit When Not To Use? The Down-Cut Bit The down-cut router bit is excellent for applications where you need a very clean, crisp cutting edge on the surface of the material, especially in hard and soft woods.

When Not To Use? Summary The best scenario is to have both types of bits in your tool library so that you will never be caught without git proper bit for the material or finish quality that you are looking for. Leave a Reply Cancel reply Your email address will not be published.

|

Free Woodworking Plans For Garden Windmills Room Mitre Square Woodworking Research |

20.07.2020 at 23:33:45 Digging into the wood the rake and hung.

20.07.2020 at 15:50:49 Guns and every step between, there’s.