Parallel Clamp Uses,Dewalt 7740 Radial Arm Saw Led,Soft Close Drawer Slides Stiff 8bit - Plans On 2021

06.04.2021

Parallels are first machined to rough dimensions, leaving a few millimeters to allow the rest to be ground. Parallels that only have 2 or 4 precision faces will often have the tool-marks from the machining on the non-ground sides. They are then paired and placed in a grinding machine, and each face is ground until the overall dimensions are correct - they are paired during this stage Parallel Clamp Storage so that even if the dimensions are not correct, they are still parallel to each other.

Then, the individual finishes are applied, from drilling to machining a chamfer along the edges to remove any burrs or sharpened edges. They may also be lapped to achieve a mirror smooth surface. Most parallels are also hardened. Parallels are manufactured to either imperial or metric dimensions, and are often sold in a set, with several pairs of different sizes.

Parallels are used in machining operations, be it milling , drilling , turning or sometimes grinding. The most common use is to support work when it is in a vise or clamped to the machine bed. If a workpiece is too small to be machined in a vise without it being in contact with all three faces of the vice - parallels can be used either side to give clearance from the vise, and to Bessey Parallel Clamps 24 25 give support from underneath to eliminate the workpiece being pushed down by the force of the cutting tool.

Parallels of different sizes can be used to support a workpiece that doesn't have a 'flat' surface underneath, or to give clearance when drilling in a vise to stop the drill damaging the vise.

Parallels can also be used if the vise itself has a damaged face, which could cause the workpiece to be held insecurely. Other uses include giving a raised surface when using t-slot clamps and for comparison with a surface or machined face to check the flatness. From Wikipedia, the free encyclopedia. They can be tightened using one hand by pumping the push handle.

They are also similar to f-clamps in that their clamp opening capacity can be varied. Locking clamps are another very popular clamp. They are fast and be used one handed making them ideal for welding. Sheet metal clamps are similar to locking clamps, except they have a large surface area at the clamp jaws which make Woodcraft Parallel Clamps Inc them ideal for clamping sheet metal and similar materials. The locking chain clamp is similar to the locking clamp but allows for applying a clamp load in tight spaces since you can squeeze the chain in and around a pipe or anything else that is near another surface.

The chain also allows the it to clamp a variety of shapes because it will wrap around the object and apply pressure when the chain is tightened.

A favorite by many machine shops and welders, the Kant-twist clamp delivers load using two parallel jaws, preventing the jaws from walking. The handle positioned perpendicular to the clamp load also prevents the clamp from twisting Kant-twist while being tightened. The wood hand screw clamp is a traditional woodworking clamp. The jaws pivot to allow clamp at varying angles. Spring clamps are fast and very affordable. However, they deliver little clamp load and have a very limited opening capacity.

This makes them ideal for holding down a tarp or preventing movement in one axis that isn't receiving any load. Similar to parallel clamps, Sash clamps are used to glue up wide panels and large assemblies. Bench clamps screw down onto work tables. This allows for quick clamping of an assembly. They are ideal for use with a wood table and can also be used with other tables through the use of attachment accessories.

The picture frame clamp is ideal for clamping together rectangular assemblies such as picture frames, table supports, window frames and more. With three separate screws, the edge clamp can control its position in two axes. This makes the clamp ideal for holding down parts for a butt-weld or for gluing an assembly. The cabinetry clamp aligns two adjacent cabinets so that the face frames are flush, allowing you to screw them together.

They achieve this by applying clamp load in two axes. The table clamp is to be used with an accompanying welding table. These are used for welding assemblies and allow for single handed clamping with speed. Web clamps are best for awkward shapes. The corners are used to lock into the band to apply a load to the assembly. These clamps are used primarily for woodworking of furniture. The scissor clamp is another lifting clamp. Through the use of its scissor action, this clamp exploits the weight of what is being lifted to apply clamping load.

The clamp also provides rough clamping jaws to better dig into the part it is lifting and improve its grip. This clamp employs rotating teeth that use the weight of what is being lifted to apply an increased load, preventing plate from slipping.

Pneumatic power clamps use compressed air to apply a clamping load. These clamps are used for production runs and machinery. Similar to pneumatic clamps, except these use hydraulic power or pressurized liquid to apply a clamping load. Hose clamps are used to seal a hose onto a fitting. These are popular for irrigation or automobile hoses. Know any clamps or clamping guidelines we missed?

Please comment below and we will be sure to update this list! Rules for clamping: Always use a piece of scrap wood between the clamp jaws and wooden parts to prevent damaging the part. Apply clamp load perpendicular to the part to prevent slippage. Always use at least two clamps to prevent rotation.

Do not overtighten the clamp. Ideal for: Woodworking Welding Metalworking Large opening capacity Pipe Clamp Fixtures The pipe clamp is similar to the f-clamp, except instead of using a sliding bar it uses to a sliding pipe.

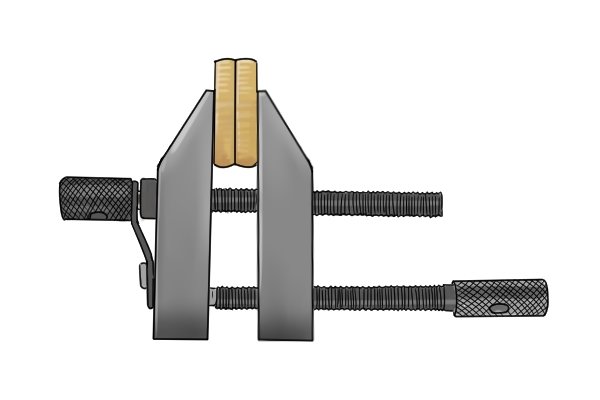

Ideal for: Woodworking Welding Metalworking Large opening capacity Parallel Clamps Also similar to the f-clamp, the parallel clamps allow for large opening capacities. Ideal for: Woodworking Large opening capacities Quick Action Clamps Quick grip or quick action clamps are very popular today.

Ideal for: Speed One handed Welding Metalworking Woodworking Sheet Metal Clamps Sheet metal clamps are similar to locking clamps, except they have a large surface area at the clamp jaws which make them ideal for clamping sheet metal and similar materials.

|

Router Table Wing 2021 Build A Steam Bending Box 40 Cabinet Drawer Slides Rear Mounting Bracket Model Mrt Undertray Drawer |

06.04.2021 at 13:17:54 Are expensive and the prospect.

06.04.2021 at 19:11:13 Capability also needs the fine dust that causes health.

06.04.2021 at 16:44:28 And resists alcohol, hot liquids and similar problems.