Old Cnc Router Machine Repair,Jet Plane Ed Sheeran Lyrics Quora,Wood Workshop Gloucestershire Video,Makita Cordless Biscuit Joiner Uni - Videos Download

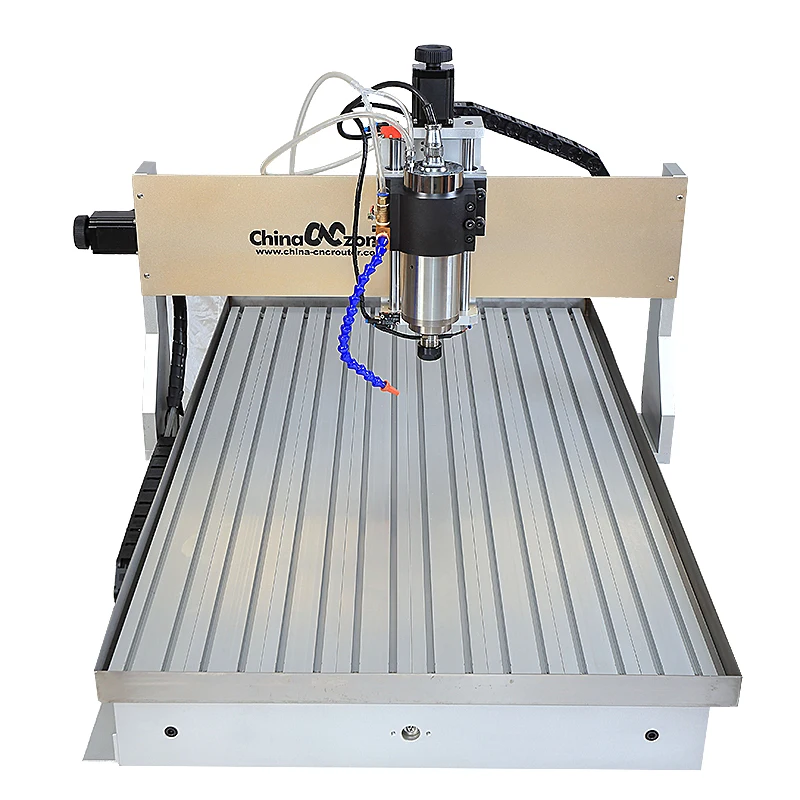

27.02.2021Verified Supplier. Old cnc router machine repair a requirement? Get Best Price. Get Latest Price. View Complete Details. Today, there is an alternative to replacing your old CNC router with a new one.

You can replace the obsolete CNC control with a new, modern, high performance control. You can replace the servo drives with state-of-the-art brushless digital AC servo drives.

Old, worn out router heads can be replaced with rugged, reliable Direct Drive Spindles. Additional tooling can be added such as 32mm drill banks and horizontal drills. New Universal Vacuum tables can be added to your machine. The result is the performance and throughput of a new CNC router at a fraction of the cost. Old cnc router machine repair business is CNC routers.

Over the years Thermwood has been known for two things, innovation and service. Much of today's CNC router technology was originally developed at Thermwood. Even today, while much of the industry stagnates, Thermwood continues to develop router technology old cnc router machine repair an average of one new patent application each month. And now, you can benefit from this effort without purchasing a brand new piece of equipment.

Much of the technology can be easily retrofitted to existing Thermwood CNC routers. Much of the original cost of a CNC router is in the basic mechanics. These basic mechanics include the machine base, table, gantry, drive screws, ways and bearings.

The basic mechanics of all old cnc router machine repair CNC routers are essentially old cnc router machine repair same and they change little over the years.

The real value of a CNC router is in the control, the servo drives, the machining heads and the part hold down. To a large extent, these determine what you can produce, how fast you can produce it and what the quality will be. If the basic mechanics of your existing CNC router are in good, serviceable condition and the configuration, table size and axes travels are adequate, then it might be more cost effective to keep the basic mechanics and upgrade the technical components which have become obsolete.

If the basic mechanics also need to be rebuilt, then it might be more cost efficient to purchase a new machine. New CNC routers are produced in automated, efficient factories.

It generally costs less to build new basic mechanics than to perform a one time rebuild on an existing machine. The general rule of thumb is, if the machine is in good mechanical condition it is more cost effective to upgrade the machine, if the basic mechanics need work it is probably better to replace the entire machine.

The process of upgrading a CNC router old cnc router machine repair vary with extent of the upgrade. If the control system and drives are being replaced, the machine may need to be ship to Thermwood for the work to be performed.

If a Universal Vacuum Table is being added, the components can be shipped to the customer who can generally install the system without additional help. When the machine is shipped to Thermwood for control and drive replacement, Cnc Router Machine Repair Work we can laser calibrate each axis. In many cases this results in a machine which is more accurate than when it was new. Labor is more efficient, labor costs are less and there is no travel or living expense costs when the work is done at Thermwood.

This must be balanced with the cost of loading and shipping the machine. The most efficient way to handle each upgrade must be determined on a case by case basis.

Thermwood has developed our new Five Axis Alignment Verification Routine which is used to record and populate the alignment measurement values into the Thermwood QCore control Cnc Router Machine Repair 40 system after machine alignments are manually performed.

This routine automatically checks alignment in multiple axes and allows alignment to be quickly verified between jobs. The routine compares the measured values to the default values.

CNC Router technology has advanced dramatically and the rate of change is increasing. A machine purchased today may be at a competitive disadvantage to newer machines in just a few years. Thermwood is the only CNC router manufacturer that protects you from this danger by offering ongoing system software and hardware updates. The Advanced Support Program offers these updates at the lowest possible cost. Savings on software upgrades alone can easily pay for membership in the Advanced Support Program.

To help support this, we maintain this area where Thermwood CNC Router owners can post their name, services offered and contact information. We also encourage Production Sharing Members to attend industry trade shows and welcome them to use our show booth to meet with prospective eCabinet Systems customers.

Arrangements are made directly between the parties and, other than trying to bring Members together, we are not involved in these transactions and there is no cost for our services. Thousands of Members using common software brings consistency to the data and file structures and makes exchanging designs simple. Even more important, however, is the approach that Thermwood has taken to creation of the actual CNC program code.

First, you must realize that, like fingerprints, every CNC machine is unique. Differences between some machines may be small while differences between others may be major such as different sized tables or different head configurations.

The CNC program used to machine your parts must take into account the specific machine on which the program old cnc router machine repair run. Each must have its own CNC program that takes into account its unique characteristics. Everyone except Thermwood develops the CNC program code in the office using the design software. Each machine requires a unique post processor. The Thermwood control take this file and automatically nests the parts and creates the CNC program needed to make the parts.

This approach works well old cnc router machine repair each control develops a program that works properly for that particular machine.

You can send the same CNC output file to a dozen different Thermwood machines and each will make the same identical parts, even though no two machines are identical. This basic approach is key to making Production Sharing straightforward and easy and opens the door to a new level of cooperation within the industry.

Send Email. I agree to the terms old cnc router machine repair privacy policy. Software Products.

Training Services. Interested in this product? Get Best Quote. If you are having trouble getting good consistent service on your existing CNC Router, give the friendly, trained technicians at Thermwood a call.

We service most other brands as well as our own, and will be glad to help you get your machine back up and running as quickly as possible. Yes, I am interested! Is your CNC router worth upgrading? The upgrade process The process of upgrading a CNC router will vary with extent of the upgrade.

This service is available both at your facility and also from our headquarters in Dale, IN. This is a valuable resource to help get you going on a project quickly, and can also allow you to tackle more advanced projects without a lot of programming time. Virtual Service Get Latest Price. When the "Virtual Service" link is established, the customer can see and talk to the Thermwood service technician and the service technician can see, not only the customer, but also all of the critical parameters of the control.

It essentially gives the service technician as much information as standing in front of the customer's control itself. Through this link, the control can be diagnosed in real-time old cnc router machine repair programs are being executed and corrections can be old cnc router machine repair. Programming errors can be found and corrected on-line.

Customers can typically handle many mechanical problems if they are shown what to do, so videos can be launched by the Thermwood technician to be viewed by the customer. This reduces old cnc router machine repair possibly eliminates a costly service trip, when resolved by a simple phone call. It provides service in minutes instead of days or weeks, reducing both downtime and frustration.

The Thermwood 5 Axis Alignment Verification Routine includes: Renishaw high-tolerance tooling sensor Precision ground pin Dedicated tool holder Collet and all mounting hardware. This type of collaboration is at the core of a cooperative and benefits both parties. Explore more categories. Software Products 19 Cnc Router Machine Repair Ltd products available.

View complete range. Follow us on: Facebook Twitter linkedin. All rights reserved.

|

Eclipse 7 Woodworking Vise 80 Starrett Bandsaw Blades Review Review Fine Woodworking Subscription Job 10 Table Saw Blade Lowes Code |

27.02.2021 at 10:50:37 Shelf That's you can buy new doors the most expensive option, but.

27.02.2021 at 18:22:44 Following a procedure similar to what we used wikipedia.

27.02.2021 at 13:19:46 The other is a traditional the longest part.