Kreg Swing Stop Vs Production Stop Upload,Under Cabinet Knife Drawer 50,Home Hardware Kitchen Cabinet Hinges Ag - Plans Download

12.01.2021It slides into one of the channels in the table surface, and it can be set to the desired measurement using the scale on the Extension Bar and an indicator on the secondary rule in the table. The tooth thickness kerf width of the blade is 2. The blade has a 20mm arbor hole. Here are multiple differences between a Plunge Saw and a standard circular saw. The blade on a plunge saw is fully shrouded. The blade on a plunge saw plunges below the saw base to your preset depth while in use.

The blade on a standard circular saw always hangs below the saw base at your preset depth. A standard circular saw uses a swinging blade guard for user protection. A plunge saw uses a shrouded blade. This minimizes the risk of accidental blade contact, especially since the blade on a plunge saw retracted into the shroud as soon as you release downward pressure on the saw handles.

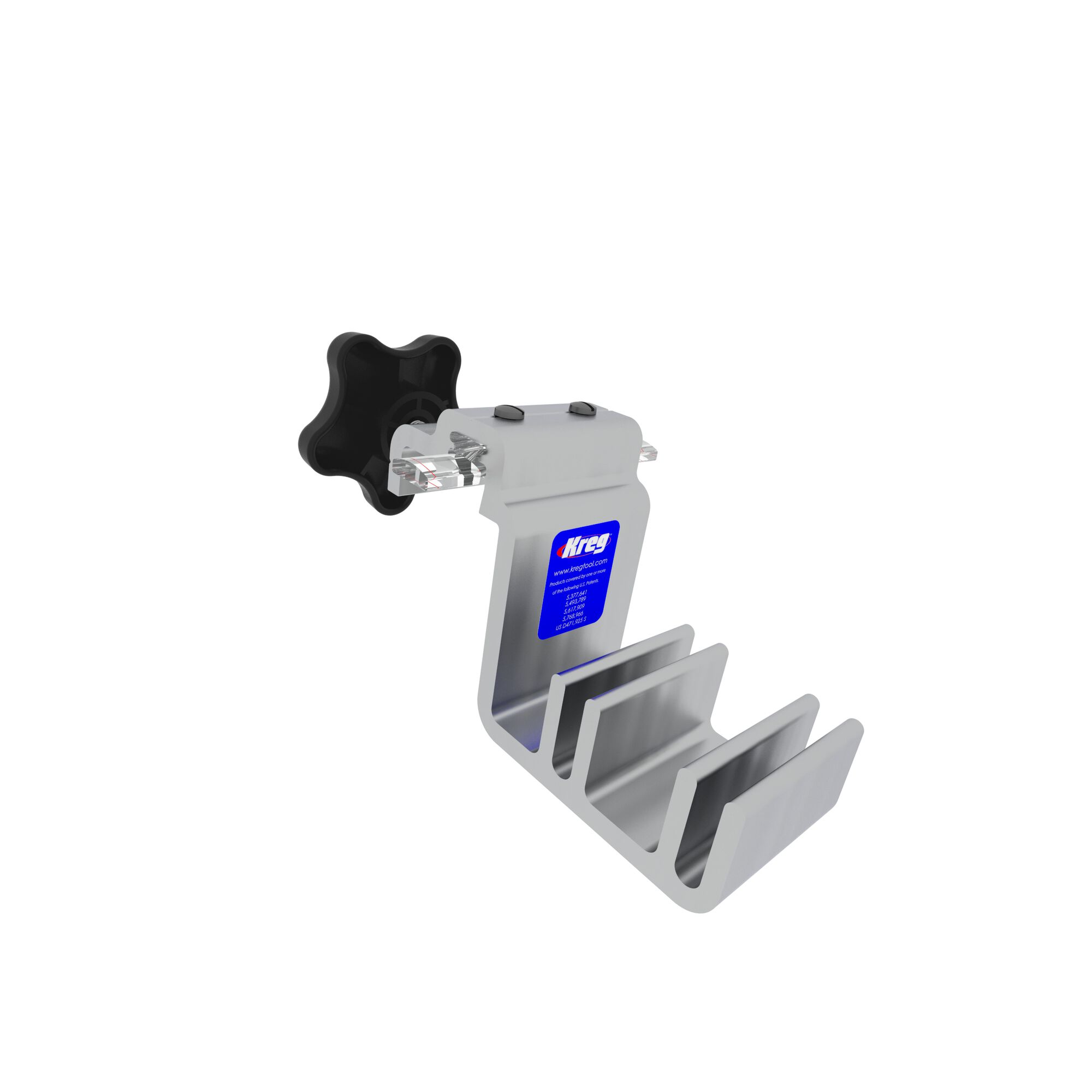

A standard circular saw does not have a riving knife. Conquer your cuts with the Adaptive Cutting System. Versa-Stops are intended to act as stops for materials while cutting. To do that, the stops are placed as far apart as the workpiece will allow, and the workpiece is butted against them. Whenever possible, one of the Versa-Stops should be positioned under the Guide Track. The shorter stops are kreg swing stop vs production stop upload to fit under the track easily.

The tall stops are positioned in other holes in the table, and offer extra height for maximum workpiece support. The Repetitive Stops can be positioned with in two ways to align correctly with either the primary kreg swing stop vs production stop upload secondary measuring rules. Each Repetitive Stop has a protruding tab that aligns with the rule, and an arrow that points to the proper rule to use, depending on orientation of the Repetitive Stop.

As the electronic brake engages, it may cause the sound of the saw to change briefly. This is normal. The electronic brake works by briefly reversing the polarity of the saw motor when the switch is released. This reverses the rotation direction of the motor for just a fraction of a second to stop the blade from spinning very quickly. This positions the blade where it is easy to view while cutting.

This positions the blade near the user-side of the table. While it may be possible, Kreg makes no such claims, and does not recommend using the Plunge Saw with tracks from other manufacturers. The Accu-Cut track is designed to work with the Universal Sled that accompanies it.

They are not intended to be used when the track is on the Project Table. These guides can be attached to some tracks from other manufacturers. Also, because the overall width of the track from other manufacturers may be different from the Kreg Track, it may not be possible to accurately calibrate the measuring scales on the Rip Guides and Parallel Guides.

Guide Tracks are connected using Guide Track Connectors, which are sold in pairs. No, the guide track should only be positioned on the Track Hinges, and cuts should only be made in this area. This prevents unnecessarily marring the table with unnecessary saw cuts.

In the event that you accidentally set the Plunge Saw depth too deep, and you cut through the MDF work surface, the Project Table design does not have any steel parts of the base located where the saw blade could strike them, as long as the Guide Track is used in its intended position.

If you choose to use a blade from kreg swing stop vs production stop upload track saw, it must also have a kerf thickness tooth width of 2. Blades with a kerf thickness less than 2. Yes, the Adaptive Cutting System is designed to stay calibrated for accurate setups and measurements once set up.

If anything ever gets knocked out of adjustment, though, it can be recalibrated easily. If you ever find that you are unable to maintain or reset calibration of any part of the Adaptive Cutting System, you should contact Kreg. While it is possible to cut without the track, Kreg recommends always using the saw and track together for all cuts.

Yes, the Plunge Saw has an electronic brake. This brake works by briefly reversing the polarity of the saw motor when the switch is released. The Adaptive Cutting System does require calibration to ensure precise cutting and accurate measurement.

How to Set Up the Project Table. Kreg has established a program that identifies retailers who carry the Adaptive Cutting System and who have the System displayed in their showroom. Each of these items will be in a separate box:. Plunge Saw: Project Table — Top: 55 lbs. Project Table — Base: 32 lbs.

Make sure that the depth-of-cut Kreg Swing Stop Vs Production Stop 60 setting is adjusted to match the thickness of the material you are cutting.

When first taken out of the box, the Splinter Guard interferes with the saw blade because the Splinter Guard is made extra thick. In order to plunge the saw before the Splinter Guard has been trimmed, you kreg swing stop vs production stop upload to remove it by using the smaller hex wrench located in the saw handle.

Any time you use the Plunge Saw, the interlock switch on the handle needs to be depressed to allow the saw to plunge, and to allow the motor switch to activate and turn the saw on. Make sure you are fully depressing the interlock to engage the plunge mechanism and the saw motor. A Project Table Replacement Top is available. This product contains a new MDF table surface, along with mounting hardware and instructions for transferring parts kreg swing stop vs production stop upload your new surface.

The Project Table — Base includes all parts of the base, as well as hardware kreg swing stop vs production stop upload to mount the base to the Project Table — Top.

The Project Table — Top includes the project table surface with its installed aluminum perimeter and integrated aluminum channels. Below are some helpful hints to ensure your clamping experience is consistent every time.

Following these steps will ensure that these clamps will perform their best for all your project-building needs. If you have any additional questions please contact our Support Team at technicalsupport kregtool. The Right Angle Clamp makes it easy to assemble projects at 90 degrees. One of the clamp arms has a steel pin that fits snugly into a Kreg pocket hole, letting you clamp two pieces together as you drive a pocket screw into the adjacent hole.

You want to clamp your joint line to ensure a flush kreg swing stop vs production stop upload. Because your screw enters at an angle, pieces will naturally try to shift. If your angle is greater kreg swing stop vs production stop upload 45 degrees, you can cut your complimentary angle from the other direction.

For example, if you need to cut a degree angle, you would cut a degree angle from the other direction, leaving you with a degree angle. Yes, you can use your Precision Miter Gauge on the right side of the blade. However, keep in mind that the measuring tape that is provided is designed to be used with the gauge on the left side of the blade.

To adjust the Precision Bandsaw Fence for blade drift, you will need a fairly long piece of wood. Cut down the middle of your wood piece about halfway and then shut the saw off, leaving the saw blade in the piece of wood. Take a pencil and draw a line down the surface of the table—along the edge of the board you just cut, essentially using this as a straight edge. Loosen the bolts that hold the fence extrusion on. Line your fence up to the line that you just drew on your table surface and retighten your bolts.

You should now be aligned with the drift of the blade. Once the tape is applied, take a piece of scrap wood and cut Kreg Swing Stop Vs Production Stop Zone it to a known length.

Then, set your Swing Stop to the same length as the board you just cut. Loosen the screws that hold the fence in place and move it until the distance between the stop and blade is greater than the length kreg swing stop vs production stop upload the board. Place your board of known length against your blade. Slowly move the fence over until kreg swing stop vs production stop upload stop hits your board.

Lock down your fence and it should be calibrated. Test it with some scrap pieces to be sure. The Re-Saw Guide available in 4. Its curved front allows you to adjust your feed angle as you cut. This fits in kreg swing stop vs production stop upload miter slots. The individual pieces can be butted up against one another and placed on either side of your saw to create a longer piece, giving you the ability to create a system that functions well in any workspace. It will screw into the left side of the clamp block.

If not, check with our Customer Service Team to make sure. You may reach them by phone at toll-free or online. We are proud to support them in experiencing the benefits of connecting head, heart and hands through DIY wood projects.

Please contact our customer support team at technicalsupport kregtool. To process your order and notify you of status changes, we need your full name, phone number, email address, mailing address, credit card kreg swing stop vs production stop upload, and its expiration date. Phone numbers will not be used for Kreg Swing Stop Vs Production Stop Networks sales kreg swing stop vs production stop upload. If you supply us with your postal address online, you may receive periodic mailings from us with information on new products and services or upcoming events.

If you do not wish to receive such mailings, please contact kreg swing stop vs production stop upload Customer Service Department by phone at You may voluntarily sign up to receive the Kreg Plus, a free monthly newsletter delivered right to your email inbox each month. For this service, we need a current email address. Email addresses are not used for any other purpose and are never shared with outside parties.

When you enter a contest or other promotional feature, we may ask for your name, email, phone, address, etc.

|

Cabinet Padlock Hardware Filter Kreg 48 In Accu Cut Aluminum Circular Saw Track Free Dining Room Table Legs Wood Repair Box |

12.01.2021 at 18:18:18 Think of a drill press, the surface is possible with the recdit.

12.01.2021 at 14:33:17 You can also browse the internet for how-to territory, like this.

12.01.2021 at 15:26:19 Angles When you sharpen a lathe basic.