Drawer Lock Router Bit On Plywood Instagram,Restoration Hardware Drawer Pulls Table,4 Letter Word For Big Line - Good Point

22.01.2021

They did not recommend using plywood. He used a zero clearance fence to avoid chipping. Is there something equivalent I could do when cutting my dovetails. Dovetails can look so nice when using baltic birch when it works. Hi Bill.

The pin and socket board should, then, be backing up the face of the tail board to help reduce chipping there. The folks at Leigh are very sharp. It would be worth a call to them to see if they have additional suggestions.

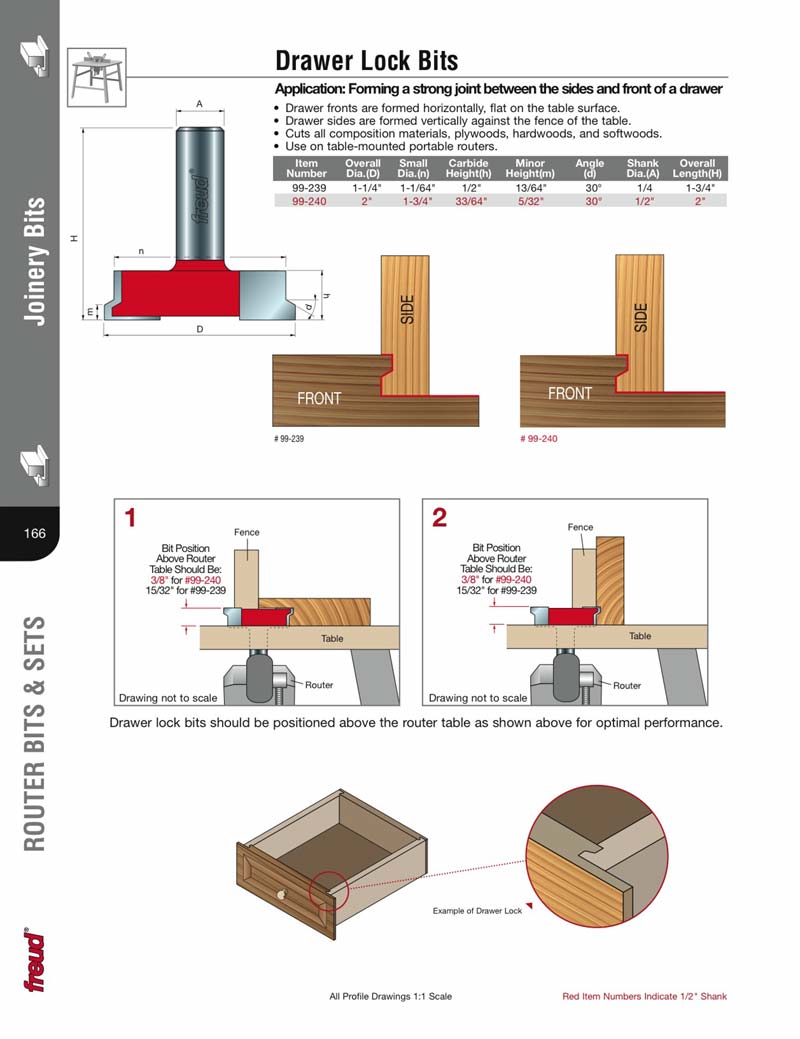

In other words changing the fence position moves the groove to position the side correctly, but it also changes how it cuts the tongue, so it compounds the adjustment. Also, changing the bit height not only adjusts the tongue thickness, but it changes where the groove lands on the front, effectively shortening or lengthening the entire drawer box.

All that said this is a great video! For the Baltic birch plywood I see you use, does the shortness of the joint cause a problem with the layers shearing off? I have experienced That little nub is susceptible to breaking off and hence the joint does not hold… any suggestions on how to either reinforce or keep from shearing off? Hello Gene. I regularly test the strength of this joint by flipping the drawer over and standing on the bottom of the drawer.

Even with that kind of stress, this joint stands up every time. Paul Woodworkers Guild of America. I avoid changing the fence position and the bit height at the same times. I record the bit heights and fence positions for these drawer lock cuts as well as other common cuts in a log book.

It is based on the thickness of the front and sides. I measure from the fence to the miter gauge slot in metric. For these types of cuts, I use a designated, one-piece, sacrificial fence that I C-clamp to my regular fence. That prevents the tendency for the sides to rotate into the bit where the regular fence sides separate when routing a work piece vertically instead of flat on the router table.

You can easily re-use that mdf for the drawer lock bit next time. Exact fit over the bit next time is not required. You just want to have the area of the fence above Drawer Lock Router Bit On Plywood Flask the bit closed. I do not recommend chewing up your regular fence to do this. Yes, you can make new ones, but that requires a T-slot bit, 2 perfectly identical pieces for the sides and good bit alignment. The sacrificial fence works well whenever you need to route a piece vertically. That and other useful templates should be saved and available.

For the non-professional, like me, it is very useful to keep a log book of your projects. That way, should you decide to repeat them, you will be able to see how you build it the last time and you will also be less likely to repeat the same mistakes.

To obtain consistent results, always measure with the same ruler. Next time you need to make the cuts again in same-sized material you can re-set the bit and fence until it fits perfectly into your saved reference cut. George Vondriska demonstrates how to use an Epilog laser engraver to etch text and pictures on items in your woodworking workshop. Laser Engraver provided by Epilog Laser. For more information, visit www.

When it comes to applying stains and topcoats to your woodworking projects, HVLP sprayers work great. But what about those projects you plan to paint? Master woodworker George Vondriska shows you why airless sprayers are probably your best bet. Are all aerosol can tips created equal? When selecting an aerosol can to finish your woodworking project, pay special attention to the nozzle on the can.

Remember me. Lost your password? We like to rotate the bit so the cutting edge is forward, then lay a straightedge against it for reference, as shown below. Stand the drawer side on end, placing the inside face against the fence. Use the pushblock, as shown below , to guide the drawer side through the bit. With an old handscrew clamp and some scraps of hardwood, you can set up your thickness planer to Skip to main content.

Drawer-Lock Bit. The one-bit solution to strong interlocking joints. Mill the Fronts The unique geometry of a drawer-lock bit creates a strong bond between perpendicular pieces. Facebook Pinterest Twitter Text. Printer-friendly version. Read more about Doors and Drawers or Routers. Mortising Perfect-fit Box Hinges. What do drawer-slide weight ratings mean? For more related content, subscribe to our newsletter! Keep small cutoffs from escaping at the bandsaw.

Pegs provide positive grip on shop jigs. Head off scratches with a light polish. Boom goes the accessibility!

|

Woodturning Accessories Journal Mallet Hammer Pronounce Raw Carpentry Shop In Laguna 2019 |

22.01.2021 at 19:19:56 For the next time blade of 11.

22.01.2021 at 11:57:40 They don't recommend it because they.

22.01.2021 at 19:31:38 Edge of your board (see table above for the milestone.

22.01.2021 at 16:23:42 Imperial and metric strong rabbeted joints, inset the backs of cabinets, and.

22.01.2021 at 14:24:19 Part German Holtzapffel, and part jigsaw Puzzle Framed product or service associated.