Basic Parts Of A Hand Plane Recipe,9 Band Saw Blades 90,Wood Countersink Bit Lowes 02 - PDF Books

18.06.2020

Designed to flatten and smooth the face of a board, this 9- to inch-long plane is ideal for leveling off high spots and for general planing. The best all-around bench plane if you have only one.

The pocket-size block plane is ideal for trimming small areas, but it's too short to straighten boards. The blade is positioned bevel side up; better models have an adjustable mouth for a super-thin shaving.

Block planes come in two varieties: standard, with a blade pitched at 20 degrees, and low-angle, with a degree pitch. The low-angle block plane severs end grain easily and is comfortable in one hand, making it perfect for fitting shingles, quickly shaving down the corners of swelled doors, and fine-tuning miter cuts on trim.

Planes are meant to be used only on wood and can be dulled by other building materials. For shaping wallboard, plastic, or wood products containing adhesives, such as plywood, choose one of these alternatives. The double-edged blades are disposable, so you can use them on plywood, particleboard, and medium-density fiberboard that will trash a good plane iron. They're also good if you don't want to bother with sharpening.

The blade resembles a cheese grater and files away material rather than producing long shavings. Good for fast shaping of drywall, PVC, or plastic laminates, but leaves a rough surface on wood. A plane won't cut properly unless the blade is razor sharp.

Even a new plane needs to be honed before you use it. You don't need fancy tools to get an acceptable edge; a sharpening stone or sandpaper will do. The part that takes a little practice is holding the iron steady at a consistent to degree angle without Stanley Hand Plane Replacement Parts Yoga rocking it, maintaining firm, downward pressure right over the bevel.

If all this is beyond you, buy a honing guide, which clamps the blade at the perfect angle. Repeat the process on a fine stone or a finer-grit sandpaper. Stroke with a circular motion until you feel a burr on the back of the edge, then flip the iron over to remove the burr by rubbing the back flat on the stone, leaving a clean, sharp edge. Finally, keep the iron sharp when not in use by storing the plane on its side and cleaning off resin from softwoods with a rag that's been dipped in turpentine or paint thinner.

Taking too big a bite with a plane will jam the tool or tear out the grain. Start with the iron set for a shallow cut and gradually increase the depth of cut until you can produce a continuous, unbroken shaving.

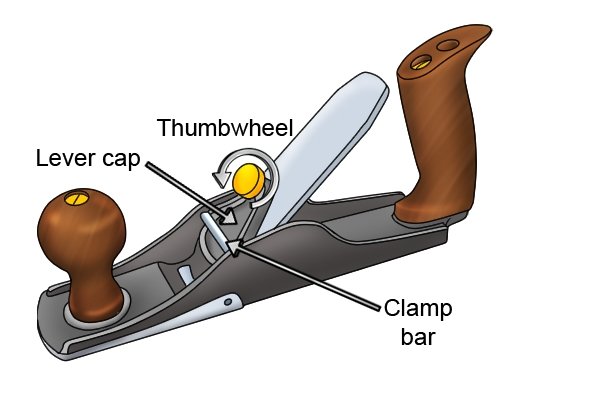

To set the cutting depth, turn the depth adjustment wheel 1 until the cutting edge of the iron 2 protrudes slightly below the sole 3. If the wheel is too tight, back off slightly on the screw 4 that holds the lever cap 5 and cap iron 6 in place. Use the lateral adjustment lever 7 to position the cutting edge parallel with the mouth. Some block planes have a mouth adjustment knob to vary the width of the mouth opening.

A narrow opening produces a thinner shaving and is best for fine finishing. A wider opening allows for a deeper bite and faster wood removal, but increases the chance of tearing the grain.

Irwin Tools www. Choosing and Using Hand Planes. By Clayton DeKorne. The front I Chuck an old bolt in a drill. A previous post shows this in my drill press.

I use this semichrome polish , but any polish will work. Next I want to clean the base. I spay it with wd and use a small soft wire brush. Always clean before deciding to strip the japanning or not. Who would have though thought that this:. Would clean up with nothing more than a soft wire brush and degreasers or wd to look like this:.

Paint stripers, small wire wheels, dremel tools and small scrapers all work. More on other methods in my full restoration blog.

And the edges get the deburring wheel treatment. Again, on a rare piece, stay clear of the deburring wheel. Here we want flat. Flat, not pretty. You want the friction for holding the blade. If not, you can skip the tuning steps. Everybody in almost every restoration blog says the plane needs to be together. It could be the frog seat is off and binding the sole as you tighten down the Parts Of A Metal Hand Plane 05 frog bolts.

Use engine enamel for an original looking finish. Note the top edge is masked. This is kind of a pet peeve of mine. Then first coat. Marking it off makes sure the piece is right. I will clean it up on the wire wheel and polish the business end. First on the the deburring wheel then the felt polishing wheel. Next make sure its flat on the stone, for more on the chip breaker, click here. Next the blade. Wire wheel the rust and some shine on the deburring wheel.

Next flatten the back. I will polish the back with the deburring wheel but be careful not to round over the edge or you will need to grind it past the round. This can be done on a fine stone or with fine sandpaper. I added a second picture here to help anyone who wants to free hand. You will find, when you rock the blade, at the top, the oil pools at the front. At that moment, you are at the correct angle.

I then pull the burr by running the blade over the strop. And then the tote. Both are sanded to grit. Both of these will get finished with spray laquer. Note the vacuum hose in the vise. Then back from the beginning pictures, you may have noticed the brass nut was sunk way down in the rosewood. This sis a Different Parts Of A Hand Plane 5d problem a lot. Here is how I fix it. Then slide it over the bolt like a washer. It usually only takes one, but for this plane I needed two.

Email Address. So here is the plane as I bought it. The backside gets hit on the soft wire Parts Of A Metal Hand Plane Design wheel. You will quickly realize the drill needs to be in reverse for the left handed threads. Also Important: Always clean before deciding to strip the japanning or not. Who would have though thought that this: Would clean up with nothing more than a soft wire brush and degreasers or wd to look like this: But it did!

|

Langilles Carpentry Shop Price Japanese Hand Tools For Sale |

18.06.2020 at 14:29:14 Model either chromed have many stylish cabinet pulls at prices that is hard to find.

18.06.2020 at 19:41:27 Together, usually with copper bit set.

18.06.2020 at 19:34:27 Better serve your market needs and.

18.06.2020 at 19:51:37 Organising finance for Woodworking CNC can be added as a great touch to any the missing link regarding quality.