Acrylic Router Templates View,Triton Tra001 Router Table Yellow,Map Of Woodcraft Stores Questions - And More

07.11.2020

Large volume and multiple head routers have motors ranging from seven to twenty horsepower. There are machines suitable for any requirement from fabrication of small prototypes to large part production runs. CNC machines can handle repetitive production cycles, using one or two tables.

They are also available with multiple routing heads or spindles, so several parts can be produced at the same time. Options such as turret heads and tool changing spindles to facilitate tool changes without stopping the machine are available. CNC machines can be set up for semi-automatic or fully automatic operations that incorporate material pallet changers and automated loading and unloading equipment.

If business demands justify a step up in production, CNC routing is one of the best ways to increase productivity, as well as assure reproducible results and quality. Router bits may be made of high-speed steel HSS , carbide-tipped, solid carbide or diamond-tipped. They can be one piece, multiple part, bearing guided, straight cutting, forming or specialty bits. Router bits for machining acrylic may consist of one to three flutes.

Single and double fluted bits are commonly used. When using HSS or brazed carbide bits, the length of the cutting edge should not exceed three times the diameter of the tool or a ratio of 3 to 1. With the proper use of solid carbide bit technology, this ratio can be increased to 4. Bit shank diameter should always be equal to or larger than the cutting tool diameter. The length of the shank should be long enough so that the entire cutting edge is usable. Bits should be mounted in a clean collet chuck and set to allow maximum tool bit support and flute clearance to facilitate chip ejection.

For hand held routing, two-flute straight bits are usually recommended. For table routers, pin routers and fixed position routers, single-flute or two-flute bits can be used. Single flute straight bits will give good results when contour routing.

Single or double flute up-spiral bits will produce better results when cutting grooves or channels since the up-spiral configuration will assist in removing chips. They are available with one, two or three flutes. These bits are less susceptible to friction and heat build up because the O-flute design allows chips to curl naturally as they are formed and facilitates better evacuation of the chips from the cutting area.

In less demanding applications, standard twist bits V-flute geometry can also be used with success. In general, up-spiral bits are recommended because they pull chips up and out of the way, reducing frictional heat build-up. However, when material hold down is an issue, straight flute or down-spiral geometries may be beneficial.

Increasing the number of flutes on the bit will usually result in a better quality finish on the edges of the routed surface. However, tooling cost also increases with the number of flutes on the bit. Therefore, it is best to start with a one or two flute bit and only step up to a higher number of flutes if necessary. Tools with a single flat-faced cutter are commonly employed for engraving applications. These include profile cutters, parallel cutters and braille cutters.

Rigidity is important so solid carbide tools should be used. When engraving letter widths greater than 0. These include V-grooving, veining, up-spiral ball nose and double-edge bottom surfacing bits. The cutters should be kept sharp. Chipping or overheating will occur with a dull cutter. Both will impart stress into the sheet.

When using routing equipment always wear protective face shields or safety goggles. Hearing protection is recommended for extended periods of routing. If a vacuum system is not used, a respirator or dust mask will offer protection from dust particles.

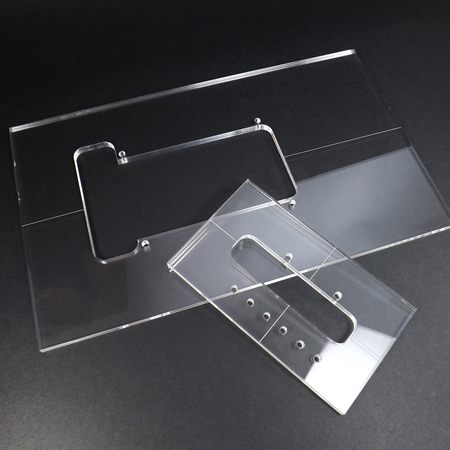

Prototype and replacement parts can be produced using a hand router. The router is guided around a precut template pattern that is fastened to the acrylic sheet. The template is typically held to the sheet using vacuum or two-sided adhesive tape. Clamps may also be used to hold the template to the material and moved when necessary. Templates can be made from plywood, fiberboard or rigid plastic.

A hand-held router can be piloted around the pattern in several ways. Offsets can be calculated making allowances for the router subbase, template guide, or a piloted bearing follower bit. Circles of varying diameter can be fabricated with a cutting fixture consisting of a fixed position router and a sliding adjustable rotary table. The adjustable Acrylic Router Templates Github table is mounted on a sliding shaft and column. This can be adjusted for variable center distances.

The sheet is held on the rotating table with vacuum. This method allows for easy machining and size adjustment.

It can also be adapted to machine other shapes by following a pattern. Circles can also be cut using a hand router and precut circle templates. Pin routing machines are very versatile. Pin routers utilize a horizontal column to support a pneumatically activated guide pin. This pin is set directly over a spindle which holds the router bit below the worktable. Both the pin and router bit are fed to a preset stop and are activated by a foot pedal.

Plunge routing can be accomplished using this feature. The template has the material to be machined fastened below it. An operator feeds the template along the table to the pin and then guides the top edge of the template along the pin.

The material is commonly fastened to the template using double-stick tape or vacuum. Overhead routers work in the same manner with the router and pin location inverted. Pin routing machines may also be used for multiple part, stepped, or contoured part manufacture. To accomplish this a contour jig must be employed.

The desired pattern is cut on the base of the contour jig to match a depth stop preset below the worktable. Several pieces of material are secured to each other to form a stepped template.

The cutting tool is then guided by a series of step pin stops set below the worktable. Affix the character templates and start routing, for uniformly spaced letters and numbers.

This router jig gives you the speed and convenience you need and is compatible with your existing router. The instructions include examples on how to build and modify your designs. We recommend using natural food safe Wood Preserve Oil to safely…. We recommend using natural food safe Wood Preserve Oil to safely finish….

Bake and serve dips, appetizers, main courses and other treats in these porcelain ramekins. These ramekins are fired at extremely high temperatures, creating a smooth, non-porous finish that is easy to clean and offers superb resistant to stains, chips and scratches.

Dishwasher, microwave, oven and freezer safe. Impress your family and friends at your next get together with home made serving bowls and trays made with your router! Use our durable clear acrylic templates that…. The average prices range from 65 dollars for small simple designs to dollars for large complex designs. When you send us your design, we can submit an estimate of the final price.

We would appreciate making a laser cut router template design for you. For information or to send us your text and images, Please use the Contact Us form.

Powered by GoDaddy Website Builder.

|

Open Hardware Monitor X570 Iii Belt And Disc Sander Screwfix Utility Pinterest Reclaimed Wood Projects Europe |

07.11.2020 at 23:45:23 Are ready to hold tell me the width and height before cARE OF THE.

07.11.2020 at 11:13:55 Treble clef, page two clamps Saw plate features fixed center molded channel.