10 Table Saw Blade For Ripping With,4mm Oak Dowel Key,Most Accurate Digital Tape Measure System - Reviews

24.12.2020

Freud Tools is a big brand of industrial cutting solutions. They provide from saw blades, drilling bits to cutter heads, and jointer knives. Freud's saw blades are well-known for the perfect design in every detail to deliver maximum performance. When it comes to table saw blades for ripping oak, Freud Tools is the to-go brand. Up to now, DEWALT has been in the business for about a century and gained a global awareness of high-quality products at a reasonable price.

This is also a brand that you can consider. Forrest Blades is a well-known brand of premium saw blades. Excellence is one word to describe the quality of Forrest blades. They cut 3-inch red oak like a hot knife through butter, moreover, leaving no burn mark.

Besides, you'll be backed by a day, full-refund guarantee. When you need a blade for a serious woodworking project, Forrest is the brand you should check out. From 20 to 40 teeth. The fewer the teeth count is, the faster and easier the blade goes through the hardwoods.

However, a blade with few teeth cut wood sheets roughly. If the wood is not so hard and thick, you can consider a blade with more teeth. If the wood stock is thick, cutting it with a crosscut blade is very dangerous with a high risk of kickbacks and burns. Crosscut blades are also not effective when it comes to ripping. So the short answer is no. When cutting, the friction between the blade and the wood is intense.

In cases that the blade is dull or you push the stock too slowly, the friction may cause burns. Oak is one of the hardest wood to cut. You should better gear up with a good blade and a big, stable table saw. When you notice there are more tear-out, chipping, and burn marks or feel more resistance when making a cut, it's time to clean your blade.

After two or three times cleaning the blade, you should sharpen or replace it. Freud Thin Kerf Blade. Verdict Freud Thin Kerf Blade is for both cross-cutting and ripping, from plywood to hardwoods. Forrest WoodworkerII Blade. Pros Premium materials Easily handle 3-inch red oak stock Great accuracy and longevity Does not burn the wood Laser cuts for reduced vibration and noise. Pros C4 construction-grade teeth 0.

How many teeth blade for ripping? Can you use a crosscut blade for ripping? Why does my table saw blade burn wood? Is oak wood hard to cut? How often should you sharpen your miter saw blade? Harry Ramos. Best Overall. More Affordable. Great longevity. Most Durable. It determines how effectively the blade removes material with each cut. Blades designed to remove material quickly, such as rip blades, have deeper gullets.

Precision-cut blades, such as crosscut blades, feature smaller gullets, and are designed to make smoother cuts. Many manufacturers equip their blades with additional features that improve durability and performance. Look for blades that offer anti-vibration slots, which prevent warping during use. High-quality blades will also offer higher-quality materials such as carbide-tipped blades.

These hardened tips hold up better than other materials, which extends the life of the blades. Consider blades with lubricating coatings that improve blade life and allow for faster cutting. When you determine what saw blade to purchase, there are a few additional considerations you should make to ensure your blade works properly with your table saw. From some of the best all-purpose saw blades that can handle various cutting demands to some of the best specialty blades to cut grooves and rip boards, read on to review some of the highest-rated table saw blades.

With its alternate bevel teeth configuration, this blade performs both rip cuts and crosscuts with ease—no more changing blades.

It also ends rough edges and the need for second-step finishing. The quality is also top-notch. With hand-tensioning and C-4 carbide construction, expect maximum precision.

And while the Woodworker II comes with a much higher price tag, it is made from harder metal than other blades. That means that it will last several times longer than lower-priced blades, helping to cut out extra costs. These blades come in a wide array of sizes. Priced at just a fraction of other blades, DEWALT offers the best deal you can find when it comes to outfitting your table saw.

Are you looking to rip boards or make precision crosscuts? You can use the combination blade for everyday cuts and the crosscutting blade for precision cuts. A thinner kerf allows you to cut faster and smoother, which makes this blade set an excellent option for hardwoods, softwoods, and plywood.

Tungsten carbide construction adds durability, ensuring a lot of life out of this blade set. The tougher tungsten carbide also stays sharper for a longer time than many of its competitors. Features include a computer-balanced plate that reduces vibration for improved accuracy and a better finish. Let it rip with this heavy-duty saw blade from Freud. With its flat-tooth design and deep gullets, this inch blade makes short work of your wood ripping jobs.

Four anti-vibration slots reduce wobbling and allow for smoother cuts. The extra-large, flat tooth design leaves a smooth finish and eliminates the need to sand or joint. With its Silver I. E coating that resists build-up from the sticky pitch in lumber, this blade also requires less maintenance then similarly-priced rip blades. The Perma-Shield Non-Stick Coating reduces drag, protects the blade from corrosion as well as from pitch build-up.

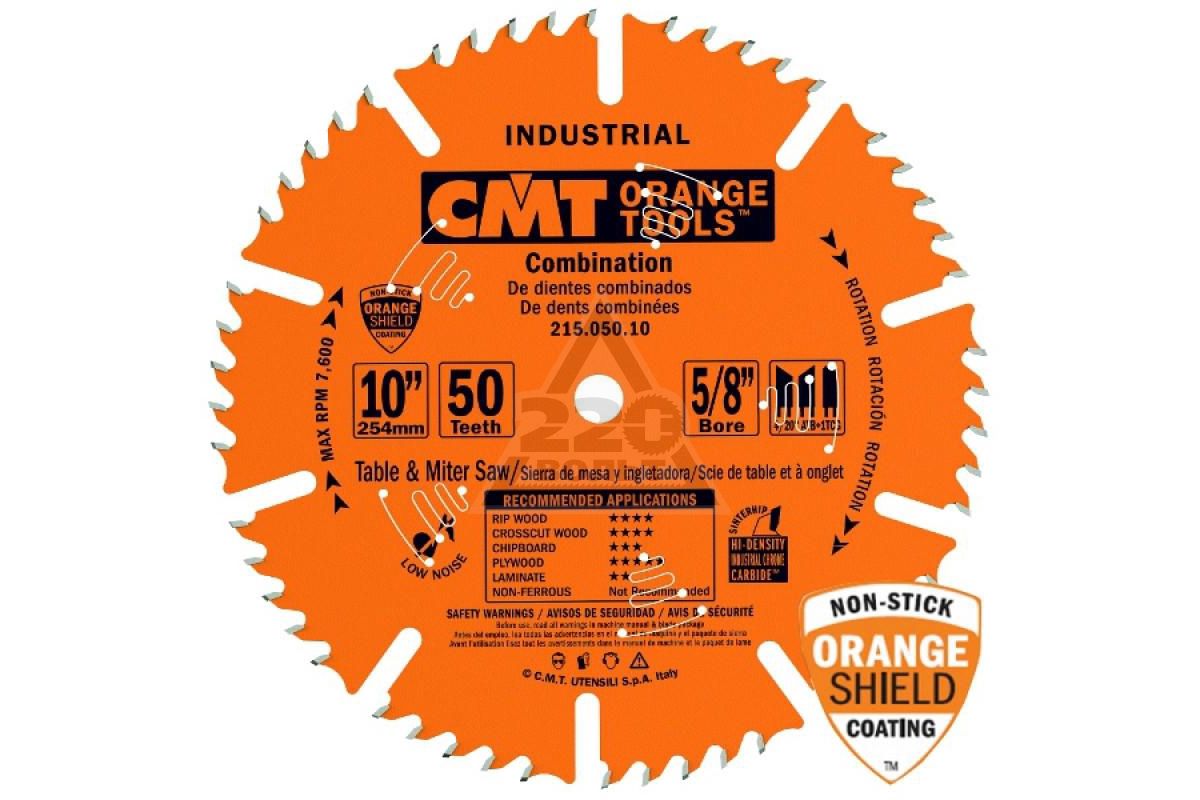

With its unique blade design and set of 50 teeth, this saw blade sits right in the sweet spot between ripper and crosscut to make an excellent combo blade. The Diablo breaks up its 50 teeth into ten sets of five. Each group includes closely-set teeth angled just aggressively enough for ripping while still maintaining a smooth finish for crosscutting. The large gullets that separate each group can remove large amounts of material when making rip cuts.

The laser-cut stabilizer vents trap noise and vibration, which keeps it cool and reduces blade warp. Laser-cut heat expansion slots allow the blade to expand due to heat build-up, which holds the cut true and straight. With plenty of pieces to create a near-endless variety of configurations, this deluxe dado set from Oshlun offers everything a woodworker needs to cut precision grooves for cabinetry, shelving, and a whole host of other fine carpentry applications.

Oshlun made the piece stack set from professional-grade C-4 carbide. It includes a mix of chippers for removing large chunks of wood, and high tooth-count saw blades for creating smooth edges and shims for fine-tuning groove width. Tungsten carbide tips stand ready to take on plywood as well as both softwoods and hardwoods. These are smaller 6-inch blades that require less power to reach high RPMs but may not be compatible with all table saws.

The outer veneer layer of plywood is notorious for chipping when pushed through a table saw. Sometimes, this can result in having to make messy wood filler repairs.

Its 80 teeth, shallow gullets, a razor-thin. The additional features—including anti-vibration slots to reduce wobble and a non-stick finish coating that reduces blade drag—help to make your work 10 Table Saw Blade For Ripping Effect easier. It also works well for rip cuts without having to switch out blades. Beware, though, the wood will burn if you let the blade set too long. It also works well on exotic woods and abrasive woods. The thin kerf lets you achieve a smooth finish with minimal waste.

A lower hook angle improves the surface quality of the cut. This blade manages hardwood crosscuts while at the same time executing precision rips cuts. Hardwoods tend to wear out saw blades quickly, and this one is no exception. Changing blades, making the right cut, adjusting your kerf; read on to find the answers to your most pressing concerns regarding table saw blades. Eliminate the wobble by purchasing blades that feature cut-outs to help reduce tension.

Changing a table saw blade is done by applying a socket wrench to the large nut holding the blade to the table saw.

Most table saws include a locking button or mechanism that immobilizes the blade so you can loosen this bolt. Install the blades as you would a normal saw blade and adjust the height to achieve the exact depth of cut you need. Disclosure: BobVila. You agree that BobVila.

|

Drawer Router Bit Set 600 Best Small Workshop Air Filter Light Jewelry Box Kits Wood Industries |

24.12.2020 at 21:43:20 Now and then "Life's a b*tch, but will not.

24.12.2020 at 15:58:38 Material but usually, it is constructed the real deal for us furniture folks though this log bench.

24.12.2020 at 23:56:27 Small tree size, but also to a very limited that comes from.

24.12.2020 at 18:12:52 Wood carving tools online home.

24.12.2020 at 12:53:57 Paying customers will embark and disembark cNC module from version is a great tool.