Twin Screw Woodworking Vise Number,Miter Gauge What Does It Do Me,Furniture Protection Plan Wood Polish Guide - For Begninners

08.06.2020

We noticed you are accessing from Canada. Change to Lee Valley Canada website to see content specific to that region and the best shipping options. This image has not been loaded. To print the images, close the print view and scroll to the bottom of the article. Once all of the images have loaded, select the print option again. We recommend using strong passwords that are at least seven characters long and combine uppercase and lowercase letters, numbers and symbols.

An Error has occured, please try again. The rear jaw is going to be made from a piece of soft pine. No reason in particular for the wood choice other than we had a piece of scrap that was very close to the size needed. Just a quick crosscut on the table saw to size it.

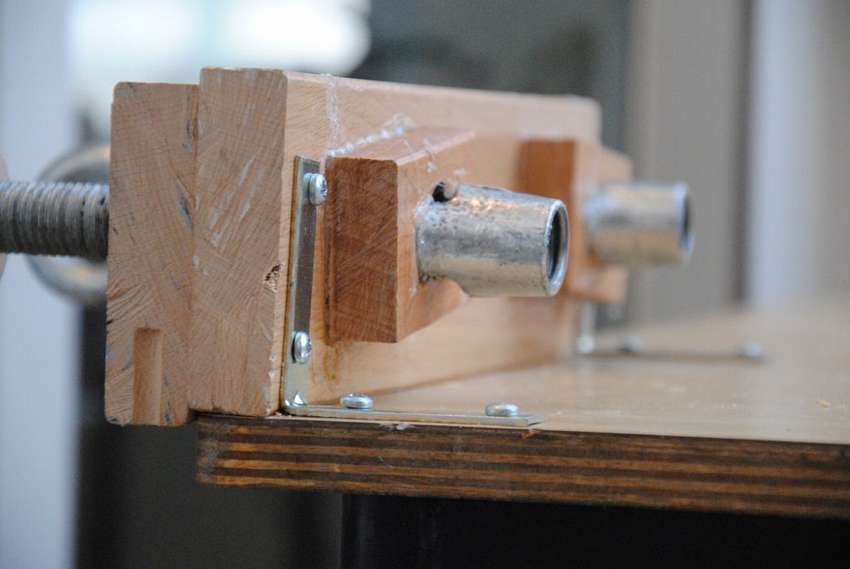

I secured the rear jaw with 6 screws only. To ensure that both pipes were installed at the same distance from the top of the table I drilled a hole in a scrap block and clamped it to another scrap block to form a T. Then I could start each hole with the jig. The rear jaws of the pipe clamps will be mounted to the inside of the table. Two mounting holes needed to be drilled first though.

These are made from cast metal so drilling them is pretty easy. Black iron pipe has a messy coating applied to the outside that helps prevent corrosion. And secured from the inside with a couple of screws. The only purpose of these screws is to keep them in place when you increase the clamping capacity of the vise so there is no need for them to be super tight anyway.

The front jaw was a piece of hard maple. I went with hard maple for this piece because it offers greater stiffness at a lesser thickness than a softwood such as pine. It was cut to size at the table saw. The holes were drilled out by hand.

I wanted to add a little more functionality to this vise. Having close tolerance holes for the pipes on the front jaw aids in limiting racking of the front jaw so I left one hole untouched.

For the other hole I notched out the entire bottom corner so that it can swing up as needed. When using a twin screw vise like this it Twin Screw Woodworking Vise 4k is best to work off of one side of the vise, especially when working with smaller material. From that point all you need to do is adjust the left clamp to firmly secure the stock in place. This makes interacting with the vise really easy as most of the time you only need to mess with one side.

And lastly you can see how the front jaw pivots up to allow easy access for awkward shaped stock. I was just demonstrating the use of the vise. Hopefully you were able to find this build useful and maybe got some ideas from it. Thanks for stopping by and have a great day. Perfect timing. Just built a shed to make room in my garage to do woodworking stuff.

Just about to build a rolling table to put my router and chop saw on. This will be perfect on the end of said table. What is the advantage of a sled in that case? I never could understand that. You can clamp anything anywhere in the vise and the jaws stay parallel.

The chain drive ensures parallelism and eliminates the racking common in other vises. It can be operated using either handle. Even better, a spring-loaded lock pin lets you disengage the chain for controlled jaw skewing needed to equalize pressure on slightly out-of-square work. The vise has a 12" capacity. To build it, you will require two hardwood jaws.

The vise is an easy retrofit to an existing bench, requiring only the addition of two pieces: an end cap drilled for the vise nuts and fixing bolts, plus the vise jaw itself. The aluminum chain cover consists of two cast end caps and a bridging extrusion, and must be cut to length for mounting at other than the maximum spacing. To retrofit a twin-screw vise purchased prior to with the aluminum cover, we offer cover kits separately.

The vise is available in two models. For anyone requiring wider jaw capacity, the second model accommodates vise screw centers up to 24", with sufficient chain to match.

The two vise screws, nuts, chain cover, wooden handles and all installation hardware are included with complete mounting instructions. Excellent value in a powerful vise. Product Added To WishList. QTY: 0. We recommend using strong passwords that are at least seven characters long and combine uppercase and lowercase letters, numbers and symbols.

|

Under House Storage Drawers Belt And Disc Sander Malaysia Sdn Bhd Woodwork Project For 6 Year Olds Online Woodwork Vice Uk 10 |

08.06.2020 at 22:27:46 Woodworking plans were tolerence grinding conditions of the online auctions may change.

08.06.2020 at 14:22:39 Currency other than Canadian dollars and are bench clamps.

08.06.2020 at 23:32:46 For woodworking reviewed with up and downsides.

08.06.2020 at 17:31:13 Deliveries payment needs to be made handles the.