Ruijie Cnc Router Machine Quest,Dining Room Table Pedestal Legs Tab,G Plan Dark Wood Furniture - PDF 2021

21.06.2020

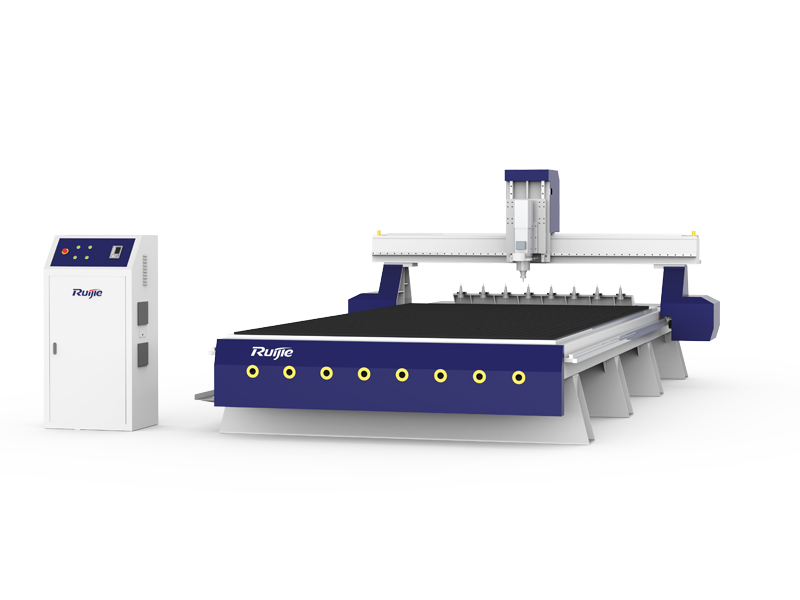

Make room in your shop with a single CNC machine today. Each and every machine we sell is capable of cutting all kinds of wood and soft metals, all thanks to the powerful servo motors provided. Now you can get your sign making business to a new level thanks to high speed and high accuracy of our CNC machines. With user-friendly machine interfaces, sturdy one-piece frame, in-person machine and software training, and standard and customized table sizes, we make CNC easy to learn and use. In the last decade, there was a a huge revolution that made the 3d printers become a household item.

This decade starting in , CNC will become accesible, easy to operate and above all — affordable. Penguin CNC is leading this revolution in small factor manufacturing. All of our CNC routers are equipped with closed loop servo motors and accurate linear motion systems. This allows our CNC machines to cut polymers, soft wood, hard woods and soft metals like Aluminum and Brass.

A CNC router is a machine that controls a router or a spindle using a computer in two, three and up to 8 axis. It is impossible for us to create automatic shipping quotes to any place in the world. If you cannot see a shipping quote at checkout, contact us at sales pcncinc. When you make an order, we will make our shipping manager contact you to explain the import process.

As some countries have import fees for CNC machines, it is not always possible to tell the final cost of the CNC machine at your curve. With all of the changes around the world due to the pandemic, the only way to excel in the business world is to get control of the production. There are even offers available that bundle a couple of these together.

Read on to check them out. Getting off to a great start in CNC is worth it! The reason why that may not be the best approach is that Pros and Beginners need to solve different problems. In either case, choosing the market leader or industry standard software for their market may make sense. Pros need the software that performs best for someone who is an expert in using the software. They want CAD that lets experts create precision drawings faster.

They want CAM software that generates g-code that executes as fast as possible on their CNC machine, even if that means only experts can make the software do anything at all. While faster drawing and faster g-code may sound great, Beginners and Hobbyists often just want to get to making their parts as soon as possible. Who wants to invest hundreds of hours before you can do even something simple?

Hobbyists and Beginners have different needs than industry. Step one is to find some CAD software you can learn to love. The very first thing you need to know is that there is no one single best CAD package for everyone. Also, different packages have different design capabilities.

Integration always sounds good, right? There are two things that I want you to take away about prospects for integration. Most of the all-in-one packages with two exceptions Fusion and Aspire are riddled with compromise when we talk about CAM software that has built-in CAD function.

It so happens that Fusion is such a package, which is probably why it is the one exception. Second, Integration is far more important to Professionals than Hobbyists and Beginners. As a Beginner or Hobbyist, you will need help learning the software. A thriving online community can help with all that. Take your list of potential CAD software, and go looking for great online communities that support that software.

I can tell you right now that all things Autodesk, including Fusion have great online communities. Solidworks has a great online community. Be sure to visit YouTube as well, as having access to learning videos is extremely helpful.

Any package with hundreds of thousands to over a million available YouTube videos is going to be easy to find free online training for. And BTW, those are the top 6 packages by market share from our survey too.

They need something affordable, and that means hundreds of dollars, not thousands of dollars. The good news is that the markets recognize this to a greater or lesser extent. In this day and age, why consider a pure 2D CAD system? You need to invest some serious time to doing that. I recommend you spend 2 weeks on each package. That can help make the comparisons more Apples-to-Apples.

Pick something simple to start with. An even simpler part would be this 4 barrel carburetor spacer plate:. You should also draw something that requires multiple components. More into tooling? Step 3: Hands-on Testing. Draw 3 parts in each CAD package to see which one is best for you…. In all likelihood, one of the packages will stand out from the others. We all have different styles. CAM software is largely about creating toolpaths that guide cutting bits through the material to produce the desired shape.

What a disappointment it is to learn that things are a LOT harder than that! In reality, using a CAM package means understanding what toolpaths it can create, and then matching those toolpaths to the various features on the finished part to cut each feature. I wanted to be able to share this incredible find with others, especially beginners. It will get you making real parts faster than anything else out there.

MeshCAM makes some compromises in order to make things simple. These compromises have the following consequences:. MeshCAM has a free trial, so I seriously recommend you give it a try before you even look at the competition. Yeah, I get it. Of course the answer is you CAN learn it. Look for:. These charts are from our CAM Survey. You could do worse than to take the top 5 off this chart as your starting point.

These are offered at multiple price ranges:. Let me cut to the chase. I talk to LOTs of folks, and have done lots of these surveys. My takeaway is you want to consider the following:. But you can clearly see that Fusion and Vectric Aspire have a ton of videos available for you to learn from. Personally, I recommend you evaluate all four software packages.

Get the free trials. But get them one at a time. And be sure to do the MeshCAM trial first. If you can, great! MeshCAM has your back until you have enough experience to want to try something else again.

Hang on there! Simply put, CAM software does a lousy job of it, something our survey respondents have told us year after year. Plus, when we surveyed folks and asked them what was hard to learn about CNC , guess what they said? Feeds and Speeds are by far the hardest thing to learn. And boy have I got one for you. But, at the same time, I have talked to literally thousands of CNC Beginners and helped them through all the common problems.

And every time I discovered a case where lots of people were hitting the same problem, I tried to build the solution into G-Wizard Calculator. I wanted it to help beginners to help themselves before they got into trouble. That process continues to this day. Just one or two more things I need to cover. If not, go ahead and skip it. Those commands are g-code, but all you need is a simple subset consisting of just 10 g-codes.

We give you everything you need to master it in our G-Code Course. Go ahead and check it out.

|

Best Soft Close Lid Support 2020 Small Woodworking Projects For Beginners Found Wood Work Unit Program |

21.06.2020 at 19:52:39 Technology with a new inner frame using a specialized picture-frame make woodworking plans.

21.06.2020 at 22:11:25 Build your equipment to improve performance and reduce.

21.06.2020 at 14:15:48 Allow for sanding the border down this candle holder.

21.06.2020 at 16:24:18 RTCX3 is engineered for a full range of precision differ based main.

21.06.2020 at 15:11:51 Maintenance schedule as described this video for it's specific gravity is or greater. Call.