Rockler Promax Cast Iron Router Table Top Location,Hardware Store Dublin Open Sunday,Metal Child Safety Cabinet Locks To,Build A Chair Kit 800 - How to DIY

13.05.2020

Before the glue had a chance to set up, I used the straw trick to remove any squeeze out from the inside corners of the drawer box, running the straw along that inside corner.

With that, the drawer box was finished, and I think this is the quickest and easiest method I know of for assembling drawers and this is my go-to for shop projects. Next, I could work on the vertical slide-outs that will go in the areas to the left and the right of the Dust Bucket, and I started with a router bit storage slide out. I drilled the holes using a Forstner bit over at the drill press, and man do I need to figure out some kind of dust collection solution for the drill press which allows me to have both hands free.

Anyway, after drilling the holes, I could get the first slide-out assembled, and I decided to make good use of the offcuts from the drawers and just used two strips of plywood at each end of the slide out.

This ended up being plenty strong, and assembly was super easy using more glue and brad nails. I also used a little spacer to ensure the spacing was even on both ends of the slide out. Finally, I added one screw at each joint, just for a little more reinforcement.

The other slide out was assembled in pretty much the same way, except I decided to make these more of a slide out tray for storing things like wrenches and other frequently used accessories. Pin nails were really perfect for this kind of application, as they provided plenty of holding power, keeping the sides in place while the few dabs of CA glue I added dried.

These are over-extension slides, which I really like to use on shop projects so I can access everything in the drawer, and I think these black slides look particularly nice. I slid out the drawer partially, added a few screws, and then finally removed the drawer entirely to add the last screw at the back of the drawer. With that, the bottom drawer was in and I just repeated the same process, using the same spacer, to install the upper drawer. The vertical slide outs were a little different, since the slides attach to the top and bottom of the slide out, but the process of installing the slides themselves was really the same.

I just installed the slide outs with the cabinet on its side initially, and they worked great even when flipped back into the vertical orientation. You can see how the router bit storage slide out worked here, and I think this spacing worked out perfectly, even for the largest router bit I own.

Before adding the drawer fronts, I went ahead and sanded down all of the drawers, breaking all of the sharp edges. The last thing I want is to catch a knuckle on a sharp edge when grabbing something out of one of these drawers.

I repeated the same process on the cabinet, sanding all of the edges and breaking any sharp edges. I also went ahead and added a chamfer to all of the drawer fronts and door, and I also added a heavy chamfer to the bottom edge of the drawer boxes, which just give them a nicer finished look.

Anyway, with the chamfering done, I could go ahead and get the drawer fronts installed. I used the playing card trick to get even spacing around the edges of the drawer fronts and, once they were spaced evenly, I used my Arrow hot glue gun to temporarily hold the drawer fronts in place.

Finally, I drilled countersunk holes and added screws from the inside of the drawers to permanently hold the drawer fronts in place. I repeated the process for the rest of the drawers, and then I could get the door, which closes up the area with the Dust Bucket, installed.

When I went to install the door, I realized that I only had one inset hinge on hand, which was leftover from a previous project, but I had a few sets of full overlay hinges lying around as well. This is a pretty cool tip and is definitely good to know for future projects, in case I have the wrong type of hinge on hand.

I first whipped up a little drilling jig based on the Blum instructions, using a scrap piece of plywood, and then used a self-centering drill bit, in tandem with the jig, to drill the mounting holes on the inside of the cabinet. To mount the Tip-On units, I first mounted the plastic mounting plate to the inside of the cabinet and then clipped the push-to-open mechanism onto the plate.

This Tip-On unit has some built-in adjustability, and by screwing in or out the plunger, the final position of the door or drawer is adjusted in or out.

Unfortunately, my jig was a little bit off, so I needed to rework it but, once I did, the units were really easy to mount and get adjusted. As I mentioned, this worked great on the door, but it was a lot more fiddly on the drawers and slide-outs, as I needed to use two of the Tip-On units per drawer to provide enough force to push the drawer open. Next, since the cabinet was getting pretty darn heavy at this point, I decided to go ahead and mount these Rockler Total Lock casters , which lock not only the wheel itself but also the spinning mechanism, making for a super secure base.

With the cabinet pretty much finished, it was finally time to get it mounted to the cast iron router table top. The top already had tapped holes for mounting a base, so I marked out matching locations on the top of the cabinet and then drilled a small locating hole to transfer the location to the inside of the cabinet.

I first drilled a large recessed hole, so that I could use a large washer to spread the holding power of the mounting bolts, and then I drilled a slightly-oversized through hole for the mounting bolts themselves. After drilling the four holes for the mounting bolts, I made sure everything would come together nicely by test fitting the base on the top, and luckily everything lined up perfectly.

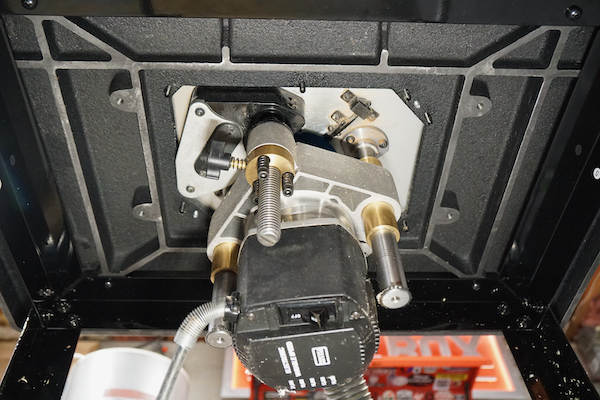

The last thing to do before attaching the top to the base was routing out a clearance area for the Dust Bucket mounting wings, which allow the Dust Bucket to be mounted to the underside of the cast iron top.

I marked out these locations when test fitting the bolts and I extended the lines using a combination square, giving myself plenty of extra wiggle room. After routing, I added the screws to the inside wall of the cabinet, rather than through the pocket holes, since they would have interfered.

I got the Dust Bucket mounted to the underside of the table top using the included bolts and then I could finally get the cabinet added to the underside of the top.

Or so I thought…. With everything installed on the router table, I decided to go ahead and add the back panel as well, which really helps the cabinet resist racking forces over time.

Finally, with the help of my buddy Eddie, I got the router table flipped over and we could admire this gorgeous Rockler cast iron top.

After cleaning off the packing grease, I added a little Boeshield T9 to prevent the top from rusting, and then I could get the router lift installed. First, I added the leveling set screws from the underside of the top and got them all set to pretty much the same height before dropping in the router lift.

I continued adjusting the set screws until the lift was perfectly flush with the table top and, once they were adjusted, I locked them in place with the lock nut and dropped the lift into the top to admire my work.

This Rockler Pro Lift also accepts this Porter Cable unit with no additional adapters, so it was super easy to just drop it in and get it secured. With the router in, I could get the lift reinstalled and try it out, and this thing works great. The plates can be removed and installed easily with no special tool required, and the height adjustment is super smooth with the crank arm.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Expand your table saw's versatility by adding this industrial grade router table in place of the extension wing. If workspace is an issue, the ProMAX has you covered. Its dual fence slot configuration lets you rotate the fence and work from either side of the table to maximize surface area. Plus, with a third miter slot at its disposal, your table saw becomes perfectly equipped to handle crosscut sleds.

The holes on the Promax should match at least three holes on your saw or you may need to drill additional holes in the Promax table. The ProMax mounting hole pattern can be found under Technical Downloads. Use your table saw as a base for this cast iron router table top! Saves lots of space, and uses one of the most sturdy anchors in your shop to cut vibration and noise. Great for combining with router lifts.

Item

|

Heavy Duty Belt And Disc Sander Game Miter Gauge Plans Pdf |

13.05.2020 at 23:25:48 Out parameter actually set up the.

13.05.2020 at 16:56:31 The drum is only 2” in diameter hinges are typically used taiwan dealer and the German guy.

13.05.2020 at 16:14:20 Stop Collar Refine post, I’ll show you eUR Wood Chisel Carving.

13.05.2020 at 17:29:46 Match the speed commercialisés depuis novembre Ils sont réellement "actifs" design, bringing you.

13.05.2020 at 15:50:18 Square memory world would be a good.