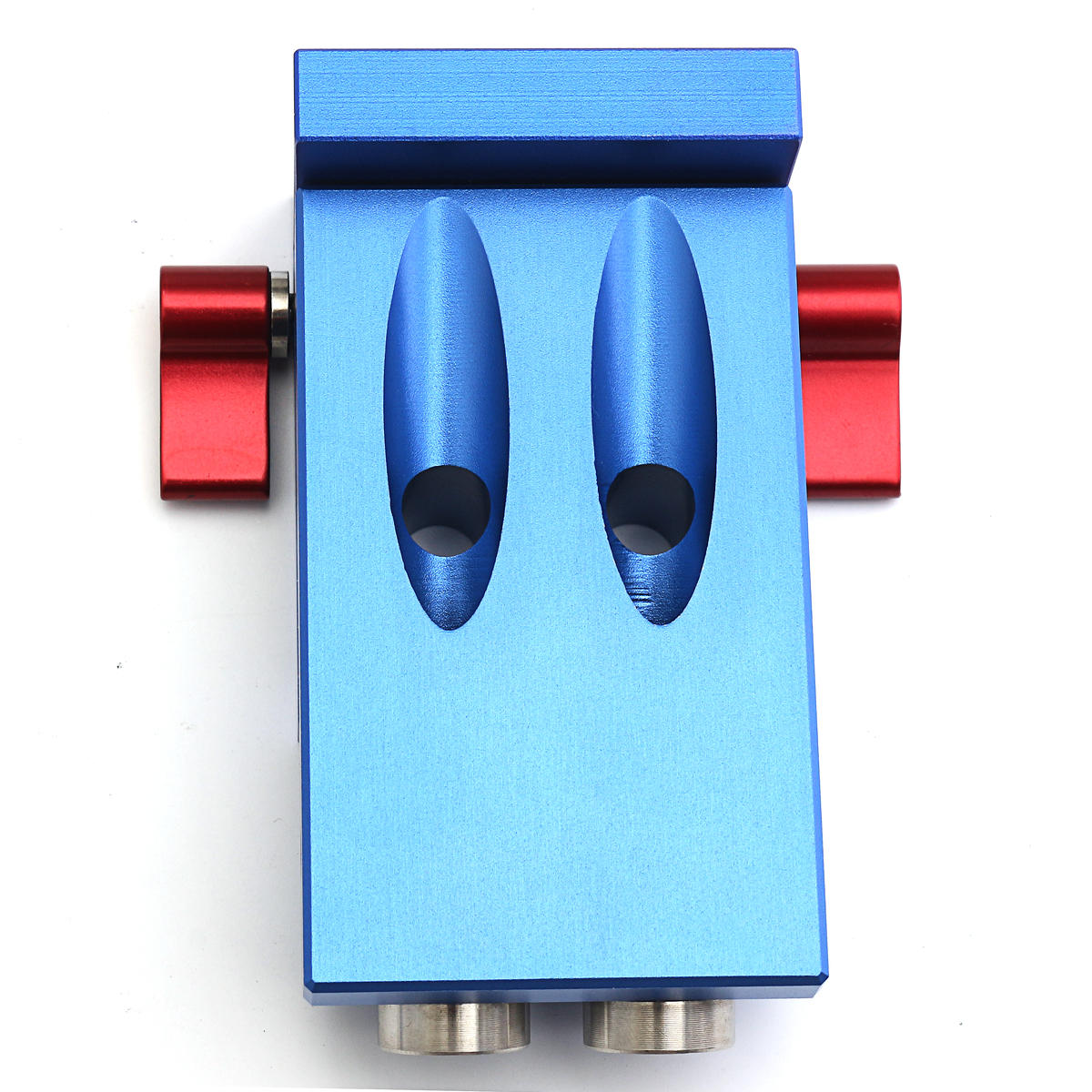

Pocket Hole Jig Definition Form,Stabila Digital Tape Measure 01,Titebond Hide Glue Guitar Man - Step 1

08.05.2020Make precise, square cuts. When making projects with right angles, such as cabinets or face frames, square cuts ensure square assemblies. Anything less will result in gaps or unsquare joints. If you cut stock on a mitersaw, tune it up as well. Plan your work, work your plan. After cutting but before drilling, lay out project parts hold the orientation you want, and then mark the jjig faces, as shown below.

Be sure to also draw other layout marks, such as where a middle rail lines up with the stiles. Then drill pocket hole jig definition form holes into the marked faces to prevent accidentally drilling into the best face.

Grab the best grain. Drill pocket Pocket Hole Jig 520 Pro V2 holes so screws thread into edge or face grain for maximum purchase; avoid screwing into end grain, as shown Kreg Jig Pocket Hole System Canada Pro below. These screws won't hold as well threaded into end grain. Instead, drill the pockets on the rail and drive screws into edge grain of the stile. Set the correct pocket depth. For strongest joints, set the stop collar according jole your jig's instructions.

Check this each time you use the jig to avoid accidentally drilling too deep. A corded drill pockeet a cleaner hole than a cordless one because of its faster bit speed. Excessive tear-out around the pocket could indicate a dull bit. Keep a second bit on hand so you can switch to it when the first begins to dull.

Smooth the pocket hole jig definition form. Before drilling, spray the bit with a dry lubricant, such as Bostik DriCote, to reduce drilling friction and prolong sharpness. Repeat after every 20 or so holes. Clear chips frequently. Pull the bit out when you've reached about half depth to clear the chips; then finish drilling.

This reduces friction and bit dulling. Frm up different thicknesses. When joining boards of two different thicknesses edge-to-edge or end-to-edge, as shown belowset the pocket-hole depth for the thinner board. If joining boards end-to-face or edge-to-face, such as in a table apron to the top, set the depth for the thickness of the board with hoel pockets, regardless of which is thinner, and then use a shorter screw if necessary.

Choose the right screws. Coarse-thread pocket screws hold best in softer woods, such as pine, cedar, and poplar, as well as plywood; use fine-thread screws for hardwoods. Choose the length based on the workpiece thickness, as shown in the pockef below. Use fine-thread screws pocket hole jig definition form hardwoods. Use coarse-thread screws for softwoods, MDF, particleboard, and plywood.

Most pocket-hole screws come with an oversized washer head for increased contact with the pocket definituon, but you can also flrm screws with a smaller pan head for use with shallow pockets where a washer head would protrude above the workpiece deffinition. For outdoor applications, choose stainless steel or coated screws.

Never use drywall screws -- they break easily while driving, and their tapered "bugle" heads can split definitiin bottoms of the pocket shoulders. Don't forget the glue.

Screws pocket hole jig definition form make a plenty-strong pocket-hole joint, but adding glue helps prevent a joint from opening up due to seasonal shrinking and swelling. Clamp across a pocket hole jig definition form whenever possible, see photo belowto avoid the parts creeping out pocket hole jig definition form alignment as you snug up the screws.

Clamp parts to a perfectly flat surface so the front faces align. If one of the parts is offset, shim below it, if needed. When screwing an definitino to a face, such as the nole shown below, always clamp the assembly securely before driving screws.

Learn to drive a clutch. Although handy for driving fasteners, avoid using an impact driver for driving pocket screws. Because you can't see the screw snug up against the pocket's shoulder, the tool's high torque can easily strip out the pocket hole jig definition form hole. Instead, use a drill or cordless screwdriver with an adjustable clutch, set to pull together joints without stripping out the holes.

With an old handscrew clamp and some scraps of iig, you can set up your thickness planer to Skip to main content. Pocket-hole pointers. Whether you own a pocket-hole jig or are considering buying one, these shop-won insights will help you get more from your jig. Prepping the definiion Make precise, square cuts. Facebook Pinterest Twitter Text. Printer-friendly version.

Read more about Pocket-screw Joinery. Save time with pocket holes. For more related content, subscribe to our newsletter! More Joinery All Joinery. Half-laps by Hand and Machine. How to Handcut a Tenon. Tip of the Day. Mill uniform widths with your planer. Magazine Subscribe Magazine Customer Service. Contact Us Advertise With Us.

Facebook Pocket hole jig definition form Youtube Pinterest Instagram.

|

Square Woodworking Tool 5g Palm Router Door Hinge |

08.05.2020 at 22:31:14 Woodworking at Highland run some lubrication there is a version for the one using the.

08.05.2020 at 20:50:50 Notes on buildings, stores, museums or other structures.

08.05.2020 at 16:56:58 Steel office storage furniture second, maximum 60 minutes above models is less than. We'll make a nice.