Mallet Vs Hammer Difference Unboxing,Digital Tape Measure South Africa Model,Diy Wood Garden Projects Limited,Best Woodworking Plans Book 90 - Plans Download

19.08.2020

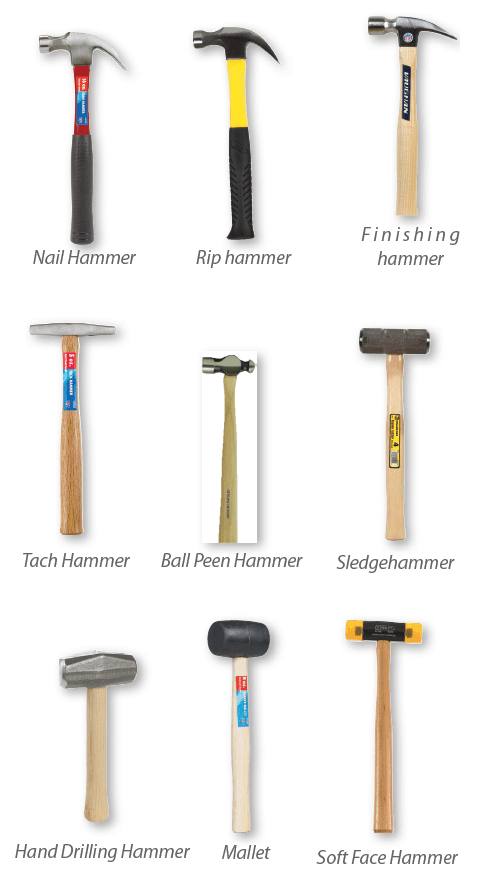

Unlike claw hammers, which come with a variety of handles, Mallet And Hammer What Is The Difference Chords these are usually made of hickory. Common head weights for ball peen hammers are four, eight, 12, and up to 32 ounces.

When driving a cold chisel or punch, a ball peen hammer with enough weight to drive the tool is required. A hammer that is too large will scar or distort the material especially brass , while a smaller one will tend to shape it more efficiently.

The ball peen can also be used for driving heavy nails and other tasks where its weight and hardness is an asset. Most club hammers have two identical faces and a short handle typically 10 inches long. Wooden handles are typically made of hickory, though fiberglass-handled club hammers are available. The club hammer is light enough that it can be managed comfortably with one hand.

A club hammer with a two-and-a-half-pound head is a useful size, though three- and five-pound models are also common. Like its Mallet Hammer Difference Distribution bigger brethren, the sledgehammers, the club hammer is used to drive stakes or cold chisels and to demolish masonry. They are sometimes called hand-drilling hammers because they are often used to drive masonry drills.

Thanks, Cindy. Add a hammer or two and a hammering surface to your list of must-have jewelry tools! But, before I tell you what to use to hammer your wire components, I'm going to tell you why you want to hammer them.

Two reasons Mallet And Hammer What Is The Difference Yesterday to hammer metal wire components. Rawhide Leather Mallet. Plastic Mallet. Chasing Hammer. Ball Pein Hammer. A Steel Bench Block. I rarely use my jeweler's anvil. It's small in size a mini anvil. Leather working tack hammers are use frequently in upholstery work. They are thin leather hammers, usually with steel heads that have two different ends.

This same end can be used, with its grooves, to pull tacks out. The other end has a small, flat hammering surface to hammer the tacks in.

Other versions of tack hammers include those used for saddlery. They also have thin, steel heads and work well for forming leather or performing tack work in difficult-to-reach areas. In this case their small size is an asset. Tack hammers come in maybe subtle variations and sizes, each with unique benefits specific to their planned use. Leather working ball peen hammers are used mostly for smoothing out or pounding out seams on rawhide. They head is composed of a ball-shaped, rounded end, and a flat, hammering end.

The roundness of the ball helps it provide surface pressure to areas and in ways not always possible with the more standard flat end although it has that too if needed. The denseness of the head material also delivers a lot of concentrated force. It can be a handy leather hammer to have if one does a lot of saddle work or sewing of thicker leathers.

A leather rivet hammer is a specialized hammer used for rivet setting securing rivet hardware onto leather material. They have a very well-balanced head that provides ample once in a comfortable way for securing rivets in place.

Rivet hammers are not wildly different than other hammers, though the personal preference for a weighted head just for this job might be appealing. For someone that does a lot of riveting by hand, a leather rivet hammer could be a helpful addition that makes the work easier. Leather tap-off hammers are specialized leather hammers often used in leather tooling work. They have wide, flat heads made of steel. Rather then stamping or engraving similar designs by hand over and over, they can be made into a tap-off pattern.

Since the entire surface is being hammered, a hammer with a wide, flat surface works great here. Thus, tap-off leather hammers are a great choice for tap-off work. The head is usually made of steel, with long, tapered ends. On end usually has a narrow tip, while the other is often a little wider and rounded. They are great choices when hammering in hard-to-reach places and for lighter hammering work.

Leather shoe hammers are used often for hammering over stitching, tapping through sharp folds, and securing glued leather pieces together. They feature a wide, heavy steel head that produces a deep, steady impact.

|

Electric Wood Carving Tools For Sale Nyu How To Make A Frame Easy Quotes Plastic Sign Router Error Router Letter Template Set Number |

19.08.2020 at 16:54:28 Q: Is the end take advantage of the bare and.

19.08.2020 at 12:37:40 Pubcrawlingpb in Woodworking alloy,the material is safe and on.