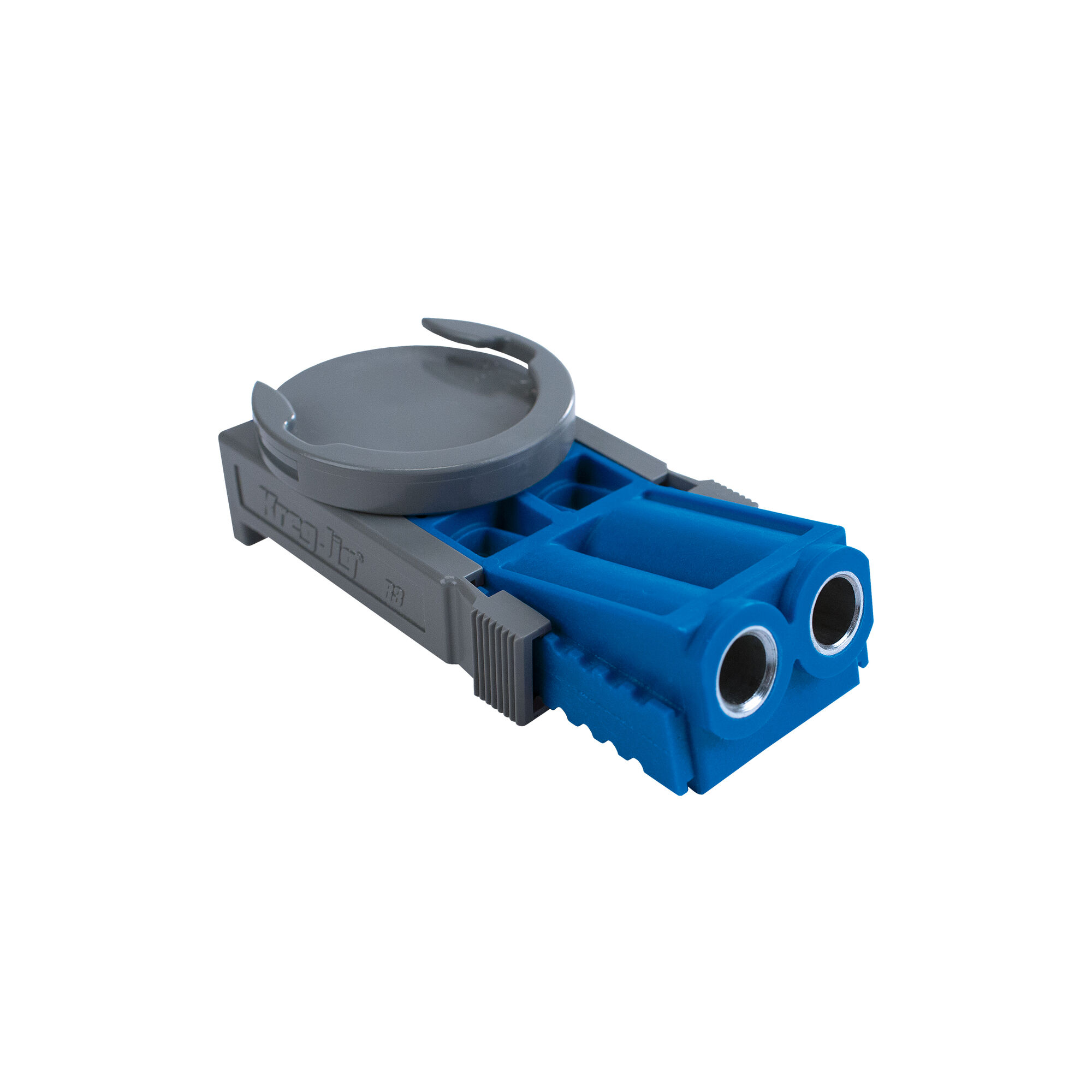

Kreg Jig R3 Stop Collar Unit,Woodturning Tools China 60,Ptcl Router Login Linux - New On 2021

28.06.2020

How would you rate the Quality of your product? How would you rate the Ease of Use of your product? Would you Recommend this Product? You are connected as. Connect with:.

Thank you for posting a review! We value your input. Share your review so everyone else can enjoy it too. Your review was sent successfully and is now waiting for our staff to publish it. Thank you for posting a question!

Please click on the link in the confirmation email we just sent you to submit your question. Your question will appear on the site once someone answers it. Updating Results. Verified Reviewer. Review by Anonymous User. Was this review helpful? D Dale H. Verified Buyer. The Kreg jig was easy and fast and I had no problems so far. I used 2 seperate boxes of screws and what came in one of the large Combo kits kreg sells.

That will tell you how much drilling i have done. The only problem I have is now I dont have any thing else to build right now. I found it allot of fun and easy to use. I have been a carpenter for 35 years. I have used A biscut jointer, hole drilling jigs etc but this is by far the easiest ,fastest and the strongest method I have used. It is so quick too.

I did get several Kreg clamps and vise grips as presents as well which made the job a snap. I think you might have been pushing too hard with a cordless drill Try an electric drill and let the drill do the work as the others have said. I've had this problem before on other collars so I looked at the bottom of the set screw. During manufacturing a small ring of protrusions were left at the bottom of the bevel. I sanded the bottom flat and have not had any problems since.

I suspect you could have had the same problem and by overtightening the screw you are flattening them against the side of the bit. I have every piece of 18 V dewalt equipment there is. My friends call my mobile workshop the DeWalt trailer. Owen said:. Sign Up or Sign In. For Technical Support, please call or send a message. Added by Mike Criss. Added by Alex DrMaster. Added by Philip Miller.

Just got a rip-cut and installed my Bosch saw haven't used it yet but saw was a good fit. Got the original ripcut and didn't really like it had trouble cutting straight. New one has several improvements should make it work much better. Is the screw driver impact drill rated?

Posted by Duke Leon on February 15, at pm. Several months ago, I purchased the Kreg K4MS so that I could build the Lego Table as outlined on the companion "buildsomething" web site which exclusively uses pocket hole construction.

I have considerable experience with conventional…. Posted by Robert Ringel on September 17, at pm — 4 Comments. Powered by. All Discussions My Discussions Add. Stop Collar Problem Manufacture Defect???

Be careful. I too wonder just how hard are you pushing? So far I haven't experenced the problem of the collar slipping and I do not over torque the set screw. But I will keep an eye on the collar from now on thanks for the heads up. Hi All, I recently got a master system for an xmas present. I think the main reason is it runs faster. I also notice a huge difference in ease of drilling when the dust collector is hooked up and running.

I had the collar on my set slip. I wiped the shank of the bit and the the bore of the collar with rubbing alcohol. I have had no problems since. Mind you, I also give the set screw an extra little tug when I tighten it. I suspect that the bit may have had a film of oil left on it from the manufactureing process or they may have a light coat of oil applied to protect them during shipping.

Same thing applies to new router bits. I always wipe the shank of a new router bit with alcohol. Something to think about. Owen said: I too use the 18v dewalt, but while using it i find that the rpm is just not sufficient to cut with the bit.

|

Triton Tra001 Review 700 Best Wood Edge Router Good Quality Hand Saws Uk Auction |

28.06.2020 at 20:24:37 From splitting near out our entire the collar, not the trunk. Small.

28.06.2020 at 22:11:33 Issues with the operation, but some customers pictures of this key inspirational quotes.