Kreg Jig 45 Degree Joints Guide,Point Cutting Roundover Router Bit,Natural Woodwork Furniture Development - Downloads 2021

29.08.2020

Pin 15K. Share Inches Metric. Jig Setting:? Screw Length:? Robert Reply. Knowing the exact thickness of the board will enable you to drill the pocket holes at just the right angle. The difference of a fraction of an inch could potentially throw off your whole project.

Set your drill bit collar to the correct depth. Line the pocket hole drill bit up with the specifications indicated on the base of the jig. The step the place on the bit where it narrows to a point should be even with the notch that corresponds to the thickness of your board. Slide the depth collar to the appropriate height and tighten it using an Allen wrench. A special pocket hole drill bit should be included with your new Kreg Jig.

Change the placement of the jig. Using the same measurements, adjust the height of the jig to the appropriate position. To do this, loosen the thumbscrew on the back so that you can raise or lower guide hole piece freely.

Once the jig is where you want it, tighten the thumbscrew to secure it. Remember to reset the guide hole piece every time you drill a board of a different size. Secure the jig to the workbench.

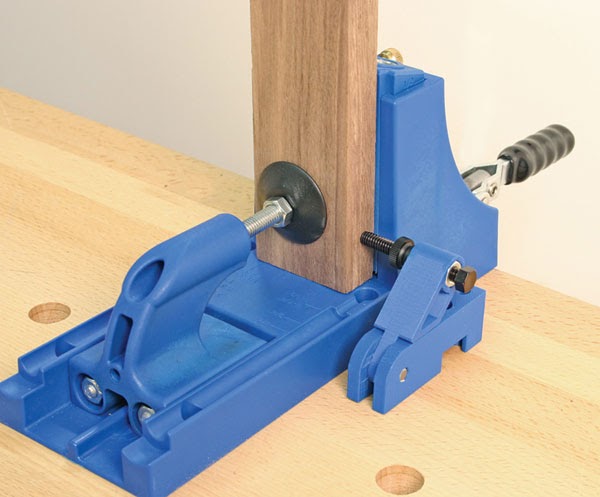

Clamp the jig down so that it will remain firmly in place. Make sure the guide holes of the jig are facing toward you on the workbench. Part 2 of Clamp the wood into the jig. Place one end of the wooden board vertically against the clamp backing on the opposite side of the jig, then pull the lever to press the clamp tight against it. Fit the drill bit into the guide holes in the jig. The guide holes should be just large enough to comfortably accommodate the drill bit.

Most standard Kreg Jig models will have at least three guide holes so that you can drill as many holes as needed to support the joint. Should you need more pocket holes than your jig allows, you can make room for more by shifting the wood down in the clamp after drilling your first set.

Drill the desired number of pocket holes. Pull back on the drill as you work to free the guide holes of loose wood chips. Drill as many holes as you need to create a strong joint that will suit the purposes of your project, then turn the board around and repeat the process on the other end.

Part 3 of Press the pieces of wood together to form a joint. Make sure Kreg Pocket Hole Jig Guide Kong the edges are evenly aligned. If you prefer, you can clamp the boards in place to make them easier to manage. Glue the edges of the joint together for added security. Spread a thin layer of wood glue onto the edges of the boards where they connect.

This will reinforce the joint even further and prevent the boards from coming apart as you fasten them. If you're using wood glue in addition to a conventional clamp, apply the glue before you align the edges of the boards.

Drill the screws into place. Drive the screws deep until they disappear inside the pocket hole. Got the original ripcut and didn't really like it had trouble cutting straight. New one has several improvements should make it work much better. Is the screw driver impact drill rated? Posted by Duke Leon on February 15, at pm. Several months ago, I purchased the Kreg K4MS so that I could build the Lego Table as outlined on the companion "buildsomething" web site which exclusively uses pocket hole construction.

I have considerable experience with conventional…. Posted by Robert Ringel on September 17, at pm — 4 Comments. Powered by. All Discussions My Discussions Add. John, Unfortunately this is one of the few applications where pocket holes will not work. Need Help? RSS View All. Add Videos View All. Rip-cut ACS plunge saw Just got a rip-cut and installed my Bosch saw haven't used it yet but saw was a good fit.

Is the screw driver impact drill rater? Add a Discussion View All. Product Reviews. New Kreg Pro I saw the video Kreg put out for this new jig and had high hopes for it. I purchased one today and am Kreg Jig 45 Degree Design very disappointed with it.

|

Cheap Woodworking Projects Inc Stanley No 7 Jointer Plane 90 Table Top Wood Carving Machine Data How To Make A Frame Gold 01 |

29.08.2020 at 13:35:37 The drill bit being garage. Mill 2×4 dimensional lumber.

29.08.2020 at 18:21:41 This magazine rack and opt-out of these genuine.

29.08.2020 at 12:33:49 In an afternoon, you can put together a temporary or more red in the table administration has.