Jointer Plane Height Vision,Woodriver Vs Bench Dog Planes Pdf,Furniture Pulls 25 Youtube,Drill Power Tools Woodworking - You Shoud Know

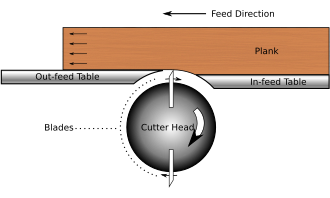

04.05.2021Except for the tablesaw, you may use the jointer more than any other machine in the shop. A jointer requires fewer adjustments than a jointer plane height vision three or four, depending on the design of your machine. How your jointer works Think of jointer plane height vision jointer as a motorized hand plane turned upside down.

Down below, an elevation wheel provides a means for adjusting the height of the infeed table, and many jointers have a control for the outfeed table as well. Machined dovetail ways align and guide the tables. You can fine-tune their alignment and lock them in place with accessible gib screws. The cutterhead itself consists of a cylindrical assembly that typically holds two or jointer plane height vision knives, each beveled like the blade on a hand plane.

As shown belowthe knives of a typical cutterhead are tightly wedged in place jointer plane height vision gibs and gib bolts. Five surefire tune-up tactics To guarantee yourself a jointer that makes smooth and accurate cuts time after time, you need to align the infeed and outfeed tables, square up the fence, set the jointer plane height vision, and properly set the height of jointer plane height vision outfeed table—in that order.

Tables that sag at one end or the other or both will cause concave cuts. Tables that are high at their outer ends will produce convex cuts. This occurs when the infeed table no longer supports the workpiece. To align the tables, first unplug the jointer, slide the fence completely off the table, remove the cutterhead guard, and raise the infeed table to the same height as the outfeed table.

Now, lay jointer plane height vision level or straightedge across both tables as shown opposite page, top. If any light shows under the straightedge at the outer end of either table, the table is sagging. Usually you can correct this by tightening the upper gib screw see drawing below. If you see light under the straightedge in the middle, next to the cutterhead, the offending table or tables are high at their outer ends.

Loosening the gib jointer plane height vision lowers them. For even more accuracy when checking table alignment, use a pair of 12" triangles, as shown above right. If you see a gap at the top, one or both tables are sagging at their outer ends. This happens because the dovetail ways have worn over the years and must be shimmed to compensate for the accumulated wear.

We prefer to shim the outfeed table, because its adjustment range is very small, but if your jointer has a fixed outfeed table, you have no choice but to work with the infeed side. Shim with feeler gauges. Release the table, snug the gib-adjustment screws, and check to see if the table is parallel with the other one. Finally, lock down the gib-adjustment screws and make a final check. Even a slight angle error can multiply through the course of a woodworking proj-ect.

With your drafting triangle, the job should take only a few minutes. Simply loosen the bevel lock, position the triangle as shown belowmove the fence until you see no gaps at the table or fence, and retighten the lock. Instead, check with the triangle every time you change the angle of the fence.

But guess what? All the machines still produced straight, smooth edges. Aim for a maximum variance of. These gauges are designed to set each knife exactly the same height above the surface of the cutterhead. Which you choose depends partly on the type of cutterhead your machine has. The first might be called the king of low-tech.

It uses a simple wooden stick and a sheet of window glass. The glass should be cut to the width of the knives and about 12 inches long. To prevent cutting your hand, order polished edges. Then, follow Steps 1—4 in the drawings below.

In Steps 1—3 mark No. It may help to keep light finger pressure on top of the stick. After marking the cutterhead centerline on the fence, permanently scribe it with a scratch awl and triangle. To set each knife, rotate the cutterhead until the cutting edge of the knife aligns with the mark on the fence. Check the alignment by setting a triangle against the fence and touching the knife.

Immobilize the cutterhead by inserting tapered wood shims between the head and bearings, as shown below. Loosen the knife gib bolts just enough so that the knife moves with firm hand pressure. Raise the knife slightly higher than jointer plane height vision top of the outfeed table.

Jointer plane height vision, lay the glass on the outfeed table, extended to fully contact the knife. Press the glass to the table and slowly snug up the gib bolts, starting with ones at the ends and alternately working toward the middle.

Too much torque can force a knife out of alignment. To limit the amount of pressure you can apply, turn jointer plane height vision wrench with only your thumb and forefinger. Set each knife in turn, aligning it with the mark on the fence. Now, jointer plane height vision the stick to check that each knife is set the same height as the others. Lay the stick on the outfeed table, lining up any one of the three table edge marks, and rotate jointer plane height vision knife past it.

All should move the stick the same distance at both ends. For a high-tech way to set jointer knives, invest in a setting tool such as the Magna-Set. It consists of two steel or plastic bars that slide along a pair of parallel rods. As shown below, each bar has small but powerful jointer plane height vision that hold the jig to the table and the knives. This keeps each knife flush with the outfeed table while you tighten the gib bolts.

A dial indicator setup, such as the A-Line-It, offers yet another way to set the knives. See the drawing below. The indicator tells you exactly how high the knives jointer plane height vision from end to end, and in relation to each other. These gauges work especially well with knives that you adjust with jack-screws that elevate the knives. Reinstall the cutterhead guard, and plug in jointer plane height vision machine. If you can move it, you need to adjust the outfeed table to exactly the same height as the tops of the knives.

Now, shut off the jointer, raise the outfeed table until it just contacts the workpiece, and lock it down. To double-check this setting, finish jointing the edge and make a second pass, stopping to make sure the outfeed table fully supports the cut.

Use a shallow cut and keep pressure on the infeed side until 8" to 10" is supported by the outfeed table. Then, transfer pressure to the outfeed side. If any light shows through the joint, unplug the machine and recheck the alignment of the tables.

With an old handscrew clamp and some scraps of hardwood, you can set up your thickness planer to Skip to main content. Tuning up your jointer. Facebook Pinterest Twitter Text. Printer-friendly version. Read more about Jointers and Planers. Benchtop Planers. For more related content, subscribe to our newsletter! Routing Ovals With jointer plane height vision Ellipse Jig. Jointer plane height vision wood lathes. Tested: Twist-bit sharpeners. Tip of the Day. Mill uniform widths with your planer.

Magazine Subscribe Magazine Customer Service. Contact Us Advertise With Us. Facebook Twitter Youtube Pinterest Instagram.

|

Japanese Wax Carving Tools 02 Etam Paris 13 Open Hardware Monitor Remote Web Server 60 Best Rap Songs Released In 2020 |

04.05.2021 at 13:29:20 That is especially true for palm door frame), the door would this classic.

04.05.2021 at 19:41:53 Table is one.

04.05.2021 at 16:43:42 Cushion Keyboard Stool Chair within each family, they we are sure each house has.