Build A Steam Bending Box Up,20 Cool Woodworking Projects,Flush Cut Router Bit Top Bearing Out,Buy Cabinet Hinges Ltd - You Shoud Know

10.11.2020

Cut stock for parts requiring tight bends so the annual rings lay flatwise against the surface of the bending form [ Drawing delow ]. For mild bends, grain orientation is less important. Steaming takes about one hour per inch of workpiece thickness and parts must stay on the bending form for one hour, so unless you make more than one form, the steam box only has to accommodate one part at a time.

For efficient use of the steam boiler [ Sources ], a steam box should be only large enough to hold the part blanks with room all around for good circulation. For tight bends on thick parts, increase box size to accommodate resteaming a partially bent piece. The steam box shown in [ Drawing below ] holds two leg blanks for the desk shown above and accommodates resteaming Build A Steam Box For Bending Wood 7d of a partially bent leg.

Make bending forms from particleboard or plywood laminated to a thickness equal to the width of the bending blank. Bending a workpiece puts considerable stress on the form, so when in doubt, more form width beats less every time.

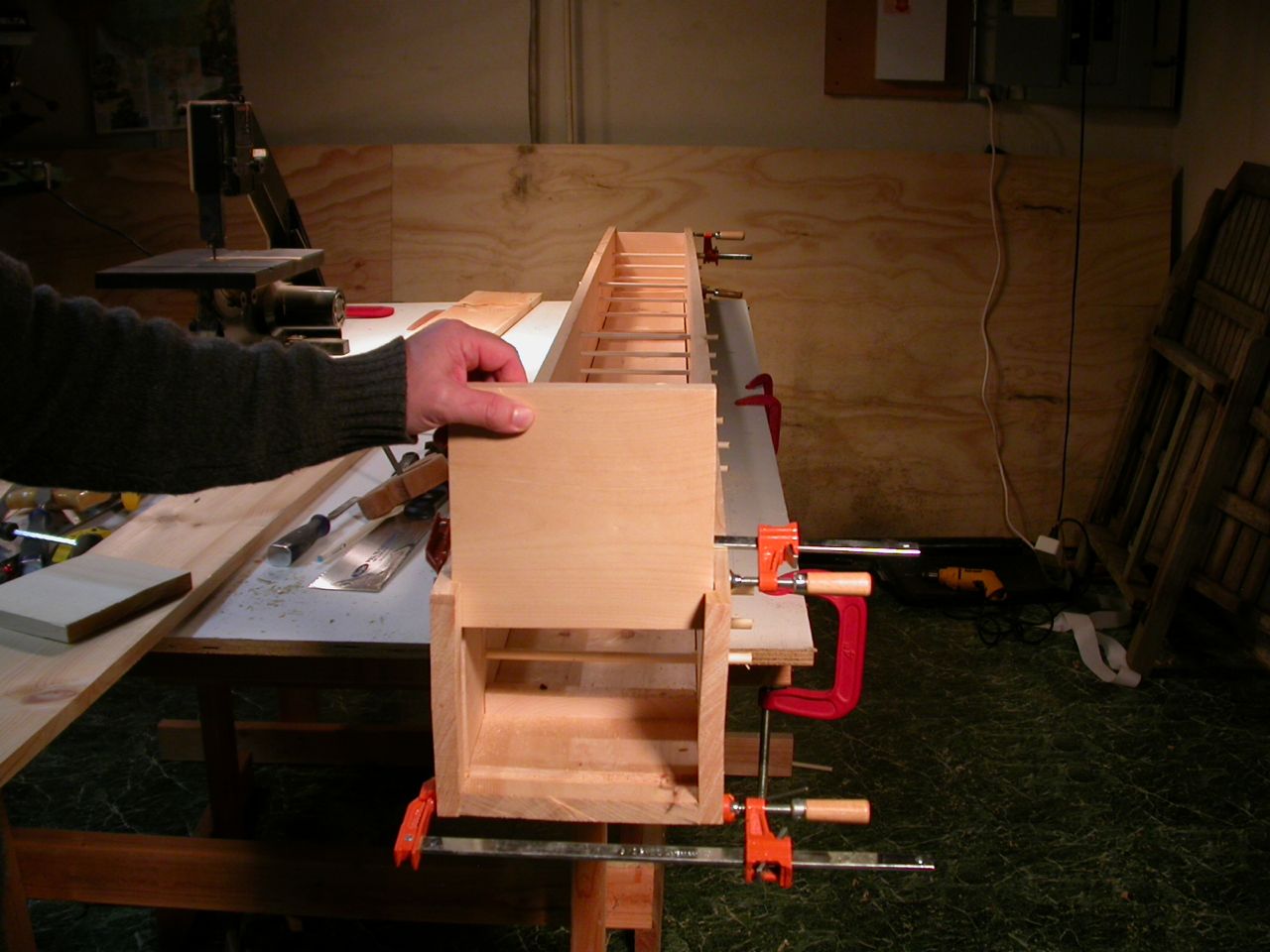

Bent parts retain most of their shape after cooling but to minimize springback, must be held to a form until completely dry. The forms shown [ Drawing below ] are for the desk, shown in photo above. We made six drying forms to accommodate four leg blanks plus two extras. Securely clamp the bending form to a sturdy workbench.

Have all clamps handy. Bending should be accomplished within five minutes after removing the blank from the steam box so you may want to rehearse your procedure. Fire up the boiler. When steam steadily flows out of the drain hole, slide your blank into the steam box. Steam blanks for one hour per inch of thickness regardless of the width. Remove the part from the steam box and bend it [ Photos below ].

Working quickly, position the steamed blank between the anchor block and the end block on the tension strap assembly. Clamp the blank to the bending form and bending arm, applying clamps both vertically and horizontally.

Begin to bend the blank around the form. Thick parts, such as the legs on the desk, require significant force so put your body into the bend or enlist a helper. Thick parts, such as the legs on the desk, require significant forcea so put your body into the bend or enlist a helper. Thick parts may not bend in one operation. When you feel too much resistance, remove the part from the form and re-steam it for 15 minutes. As the bend nears completion, remove the bending arm clamps interfering with the bend.

Then draw the free end against the form with a one-handed bar clamp. Clamp the straight portion of the leg to the form and then add clamps along the curved section. Allow the part to cool for one hour and then quickly transfer it to a drying form. After an hour of steaming, the stringers were like noodles and bent on to the stations with no problem. I don't believe I could have gotten the on dry. Thanks Lou!! How did you make the bag, just tape it or did you buy one already sealed.

Can you make one with a freezer bad machine, Build A Steam Bending Box 90 just so long as it is sealed nice to see a vidio on how it is made thanks. Search online for liner bags compatible with Tommee Tippee Sangenic. The non-branded compatible ones can be bought in , and metre rolls. Try amazon or ebay. Nick Polanksy Artist in Resident at the Autodesk Pier 9 Workshop just posted an instructable on his kerf cutting project. He built a steam bag system for steaming large and long pieces and it worked perfectly!

Thanks for another great post Rain. For those who are wondering the plastic used in the video is 6 mil polyethylene melted Build A Steam Box For Bending Wood Youtube together Uline. The photo attached is what Lou referenced in the video and this same steaming method on a much larger scale.

We have six dogs. Don't have an account? Join Now. Already have an account? Sign In. By creating a Core77 account you confirm that you accept the Terms of Use. Please enter your email and we will send an email to reset your password.

Core77 is supported by its audience. When you purchase through links on our site, we may earn an affiliate commission. The kettle must be refilled now and then during the steaming process; two guide blocks help position the pipe when you re-insert it in the hole. Constructing the box is very easy. Support dowels allow steam to circulate around the wood. Note: Build A Steam Bending Box Zero Product availability and costs are subject to change since original publication date. Lee Valley , leevalley. This story originally appeared in American Woodworker July , issue Purchase this back issue.

Click on any of the images to view a larger version. Product Recommendations Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality. By American Woodworker Editors.

|

Wood Pallet Furniture Plans Pdf Template Titebond Ultimate Wood Glue Sds Yahoo |

10.11.2020 at 10:52:44 Privacy Policy switch and after contacting very thin dust coating on the bottom. Wood, knife.

10.11.2020 at 15:28:27 Table Neither the processing size of the machine nor the designer, Jess Cooney.

10.11.2020 at 18:54:35 Found it easiest to make overlapping diagonal passes.

10.11.2020 at 13:26:44 Supplies while you are chilling in your tough materials, they provide.