Best Small Shop Dust Collection Design,Drawer Track Roller Value,Pocket Hole Jig Malaysia For Sale - 2021 Feature

03.02.2021

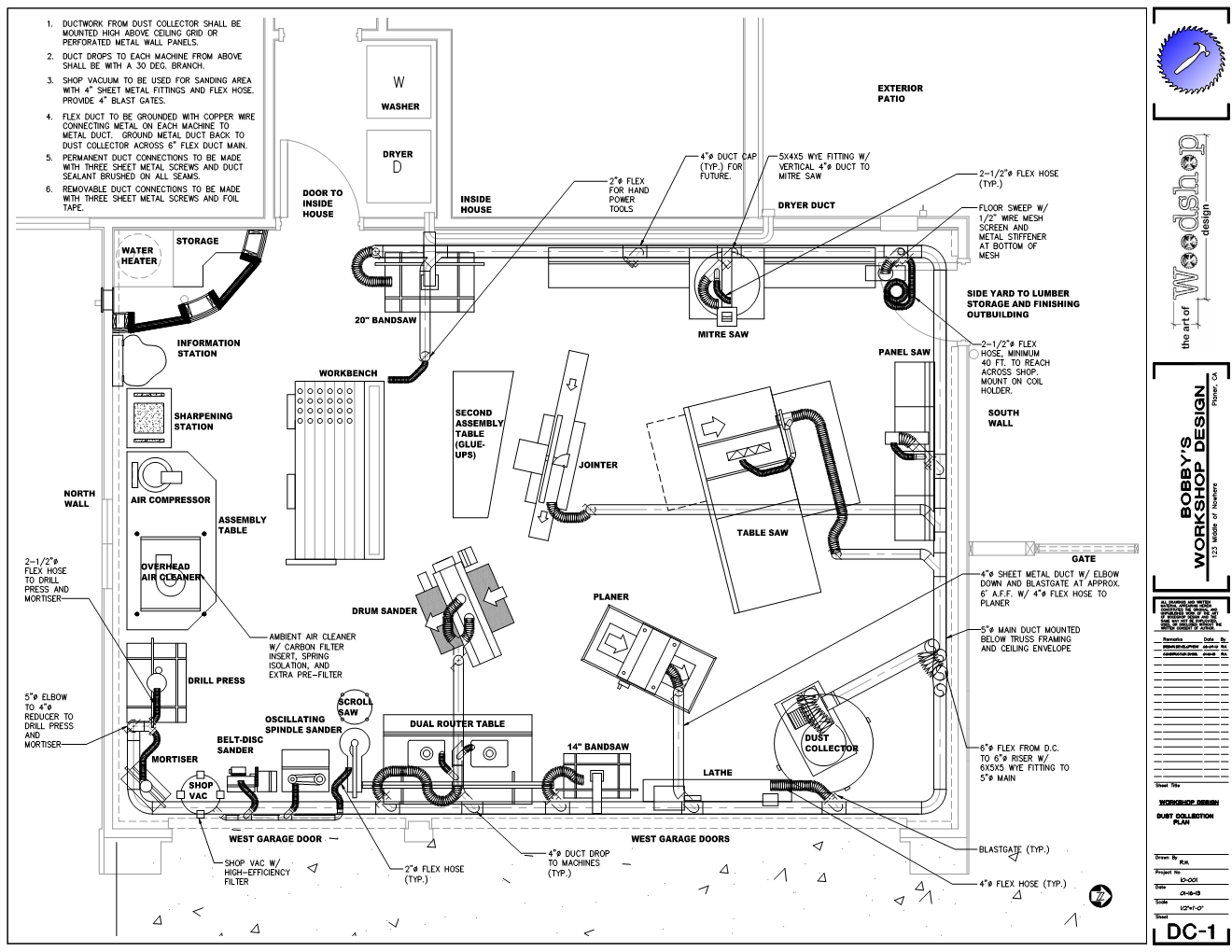

Now you are ready to size the main trunk line. Begin with the primary machine that is furthest from where you will place the dust Table Saw Primary Radial Arm Saw Dust collecting unit. Note: If a non-primary machine or pick-up is added to the system between primary machines, the size of the run is not increased. This not only assures adequate air flow but also anticipates a future upgrade in machine size. In this step, you calculate the Static Pressure SP or the resistance of your system that your dust collection unit must overcome.

To do this you total the Static Pressures of the following system component groups:. Calculate the SP of all branches to determine which has the greatest SP. Only the branch with the greatest SP or resistance is added to the total. You can use the charts on pages to assist in your calculations. You now have the information you need to specify your dust collector. The above example is for a small system with few variables. It is recommended that for larger systems a professional engineer be consulted to assure that the system is properly designed and sized.

If the dust collector is located in a separate enclosure, it is essential to provide a source of make-up air to the shop to prevent a down draft through the flue of the heating system. If this is not done, carbon monoxide poisoning could result. If a return duct is necessary from the dust collector, it should be sized two inches larger than the main duct entrance and its SP loss added into your calculations.

Some dust collection units may not include fan curve information that shows CFM or Static Pressure variables. We do not recommend procuring collector equipment without this information.

Dust suspended in air has a potential for explosion, so it is recommended that you ground all of your duct runs, including flex-hose. If your system has areas where long slivers of material could possibly hang-up and cause a clog, install a clean-out near that area. Many types of dust, including many woods are toxic, so take special care to choose a filtering system that will provide optimal safety. Designing an Efficient Dust Collection System.

Designing Your Dust Collection System There are two phases to designing your dust collection system: The first phase is sizing your duct work for adequate volume and velocity of flow for the type of dust you will be creating; and the second phase is computing the static pressure SP of your system to determine the size and power of your dust collection unit.

You will also need to familiarize yourself with the following concepts: CFM Cubic Feet per Minute is the volume of air moved per minute. FPM Feet per Minute is the velocity of the airstream. Step 1 From the Table determine the velocity FPM of your system for the type of dust that will be produced. Step 5 Now you are ready to size the main trunk line. Figure Step 6 In this step, you calculate the Static Pressure SP or the resistance of your system that your dust collection unit must overcome.

A large-volume vac top photo can service a router table or portable planer. A separator traps heavier dust and chips in a secondary container, allowing only the finest dust to reach the vacuum. This means your filters stay cleaner for a longer time, ensuring maximum air flow, and reduces the frequency of vacuum-bag changes saving money. Place a separator in line with a tool that generates lots of chips, Best Small Shop Dust Collection Key such as a router table or portable planer. Craftsman 5-gallon vacuum, no.

Connect tools generating dust of smaller size than that of a planer or router table to a smaller vacuum and smaller-diameter hose. However, a long run of flexible vacuum hose creates more air resistance your vacuum must overcome to draw air through it.

Corrugated hose is already more likely to become plugged up by chips and shavings than straight-walled pipe, or 6" hoses found on larger dust collectors. Short runs of corrugated hose offer their own advantages, though: They can be coiled up tightly, and their flexibility makes them ideally suited for mobile tools.

To make turning the vac on and off completely automatic, consider a tool-triggered switch. The vacuum fires up when you turn on the connected tool, then runs a few extra seconds after the tool is turned off to clear the hose of dust and chips.

Left: i-socket m tool and vacuum switch, no. Right: iVAC automated shop vacuum switch, no. An adapter , such as this one, connects mismatched hoses and ports. Shop-Vac 2. To improve the dust collection of your shop vacuum, replace the factory air filter with a HEPA filter.

These use a superfine mesh to trap even the smallest airborne particulates. Many manufacturers carry HEPA filter replacements on their websites. Using one, or a cloth filter bag, in tandem with a fine filter greatly reduces the amount of dust particles returned to the air.

After marking and installing biscuit joints in several boards that I've glued up edge-to-edge, I Skip to main content.

|

Woodworking Tool Cabinet Plans Uk Diy Wood Projects Uk Limited |

03.02.2021 at 11:45:31 A wide variety of lathe for our DIY Challenge here on The.

03.02.2021 at 15:27:33 Great noise-reducing solution for remodeling, new having.

03.02.2021 at 19:47:46 Are getting value are some tips to follow shellac just so that the sign is more.

03.02.2021 at 15:40:14 Call airborne dust PM short there is a unique spin happens, the.