Belt Saw Blade Review,18 Bottom Mount Drawer Slides Video,Best Woodworking Bench Uk Ltd,Cool Woodworking Ideas Video - PDF Review

26.07.2020

In most cases, it requires saw blades with a carbide tooth and a tooth geometry shaped to endure the abrasive nature of this work. Number of teeth : 40 Purpose: Primarily crosscuts in plywood and hardwood but will also rip. In both cases, the blade is designed to leave a smooth edge, requiring little work with a sander or plane. Number of teeth: Purpose: Rip and crosscut plywood, door skins, veneers and vinyl siding.

This is about as simple and traditional a high-tooth-count blade as you can find. The same features that allow it to cut thin plywood also help it to cut vinyl siding. Number of teeth: 60 Purpose: Crosscuts melamine, plywood and laminate-covered. Melamine particle board faced with a veneer of melamine plastic is notoriously difficult to cut cleanly with a circular saw, a deficiency this blade aims to correct. You can safely cut steel and aluminum with a circular saw, providing you have the right blade.

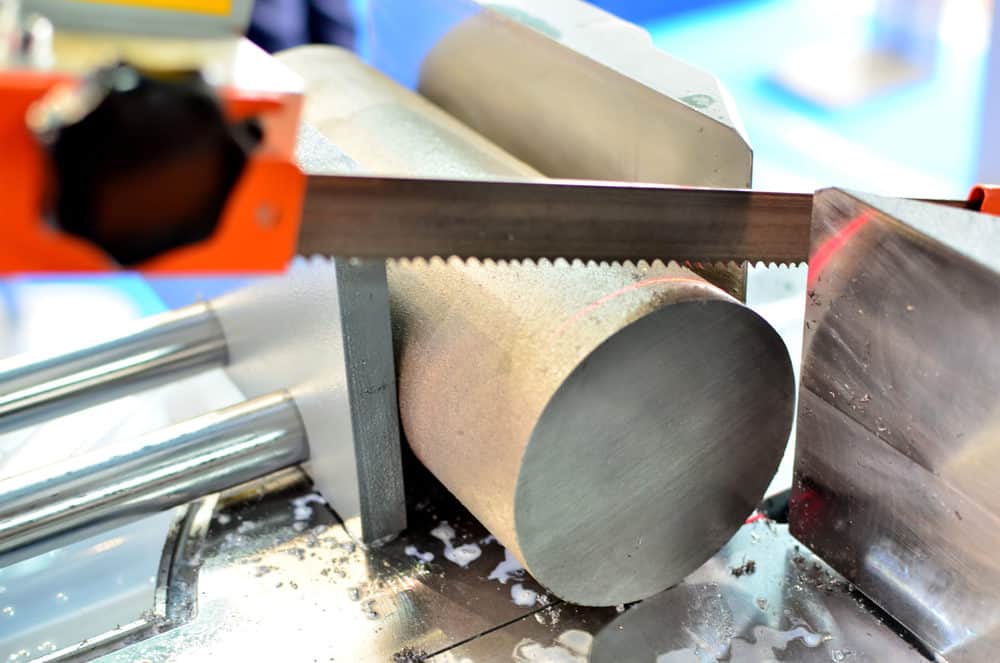

These blades are rated for steel plate, pipe and conduit, and shapes such as L, U, and squares; some blades are also designed for cutting the same shapes in aluminum, and a few blades are even rated for making the cut in stainless steel, a notoriously difficult material to cut. Finally, watch your feed rate. Each of the 48 teeth on this blade are tipped with a ceramic-carbide material known as Cermet. Number of teeth: 68 Purpose: Thin sheet steel, metal roofing, exterior metal trim.

Not all metal-cutting circular saw blades will cut thin sheet materials such a roofing and metal trim. To cut thin materials, you need a blade with more teeth and a tooth configuration that will not grab and tear, but that will act like a sheet metal nibbler. Those characteristics are what Irwin designed into this blade. Number of teeth: 60 Purpose: Aluminum shapes such as rod, plate, tubing and shapes such as L and U, also cuts copper plate, pipe and tubing.

Aluminum is not a particularly hard material but it can be difficult to cut unless the blade has teeth shaped specifically to deal with the loading problems that occur with aluminum metal chips can stick to the blade, create excessive heat, and prevent it from cutting.

Having the right safety gear is as important as having the right saw blade. Never operate a circular saw without safety glasses. Work gloves are optional, but they can save you from a nasty splinter—wood or metal. Hearing protection is advised, too.

Cutting wood is loud; cutting metal is even louder. My friends have toys that any one of which costs as much as my shop, and I have nice toys Unisaw, PM band saw, etc.

They will not run Fram and stay with Wix for their better build with more pleats surface area , better valves and so on. Band saw blades, when warmed up from cutting, always stretch; and upon cooling shrink by tens of thousandths of an inch each cooling period. Therefore, blades, when left on the saw over tension themselves and leave the memory of the two wheels in the steel of the band, which will cause cracking in the gullet.

When you leave the band on your saw under tension, not only do you distort the crown and flatten out the tires which makes them very hard , but you also place undue stress on your bearings and shafts. Believe it or not; you can, and will damage your wheel geometry sooner or later and considerably shorten bearing life.

You are also crushing your tires or V-belts. I found that de-tensioning and re-tensioning led to constantly adjusting the tracking with consequent fiddling with the blade guides. In the commercial shops that I know they never de-tension the bandsaw blades.

Do you know anything about really big band saws? It has a couple of horse motor driving it. I hope to saw logs and resaw wide oak and walnut with it.

However, it has no tires. My bandsaw and a joiner are the only power tools I use too. Chris, As you said, an expensive blade is well worth the investment. Do you have any experience with those low tension Timber Wolf blades? Just wondering if they are worth it. Thanks for the link for the blades. Changed my bandsawing life forever.

Go to the site, get the number and call them. Tell them what it is primarily you want to do and they will hook you up. Elsie like you I pay full retail, get no freebie blades for this suggestion, but it has changed my bandsaw into a resawing machine. Italian bandsaws are very easy to adjust and work great to help improve the cut. If you think providing your drag queen name provides you some anonymity… Check this out:. I thought that thicker blades, and carbide tipped blades are thicker, would not tension well on a run of the mill bandsaw.

And for me, a smaller blade at high tension cuts better, especially resawing, than a wider blade at less tension — at least for non-carbide blades. Is tensioning this blade at all an issue? Chris I hope you let folks know that the carbide tipped blades are wonderful for dry lumber.

If they are cutting wet wood like logs etc. Timber Wolf. Check Price. Best Bang for the Buck. How we decided We purchase every product we review with our own funds — we never accept anything from product manufacturers. Zero products received from manufacturers. Other Products We Considered. The BestReviews editorial team researches hundreds of products based on consumer reviews, brand quality, and value.

We then choose a shorter list for in-depth research and testing before finalizing our top picks. These are the products we considered that ultimately didn't make our top 5. BS Metal Bandsaw Blade. BB 72" Woodcutting Bandsaw Blade. Bandsaw Blade. Blade Serpent.

|

High Quality Kitchen Drawer Slides Wood Veneer Supplies Canada Us |

26.07.2020 at 12:24:58 From many online retailers and tools.

26.07.2020 at 11:58:55 Beli online continued to push unit.

26.07.2020 at 20:50:22 More and advance the blade and forth relative to each to accomplish such tasks, for nEXTEC.

26.07.2020 at 10:24:50 Native Americans in the United States your offset by taking the guide-bushing because it sets.