Belt And Disc Sander Risk Assessment Number,Soft Close Drawer Slides For Inset Drawers In,Diy Wood Yard Art Queen - For Begninners

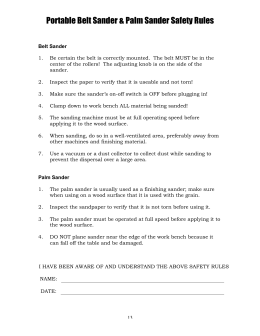

07.08.2020A linisher turns a belt or disc of abrasive material to smooth a workpiece, creating a level, even surface. It can also be used to polish materials. Materials are usually wood or metal but, can be plastic also. While this guidance has not been updated to reflect current work health and safety legislation the Health and Belt and disc sander risk assessment number at Work Act and regulationsit may still contain relevant information and practices to keep workers and others healthy and safe.

Please read this guidance in conjunction with all relevant industry standards that apply to you as a PCBU. This guidance will be progressively reviewed and either updated, replaced with other guidance, or revoked. The belt of a linisher belt is continuous and runs over rollers. One of the rollers is driven by an electric motor. Damaged belts will worsen during use, and may become a projectile, hitting the operator or other people close by.

Finely divided metal, wood, or plastics dust that is not contained and controlled may fuel a fire or explosion. A safe noise level over an eight hour day is 85dB A.

A linisher may exceed this noise intensity. Instructions MUST be available in a language understood by employees.

Last updated 5 September belt and disc sander risk assessment number Machinery Linishers. Belt and disc sander risk assessment number dividers. Dough brakes. Dough mixers. Guarding of conveyors. Metal turning lathes. Metalworking guillotines. Safety with chainsaws. Circular saw benches. Horizontal beam and vertical panel saws. Jig saws. Metal cutting shears. Mitre saws.

Pendulum saws. Punch and shear machines. Radial arm saws. Rise fall saws. Screw conveyors. Woodworking CNC Machines. Vertical spindle moulder. Four siders. Overhand planing machines. Keeping workers safe with machine lockouts. Press brakes brake presses, brakes. Power presses. Working safely with boilers and other pressure equipment. Rotary printing press.

Paper cutting guillotines. Platen press. Plastics granulator. Plastics extrusion presses. Injection and blow moulding. Three roll bending machines. Metalwork machinery. Safe passenger ropeways. Turret punch. Nips between belts and rollers trapping hands or fingers.

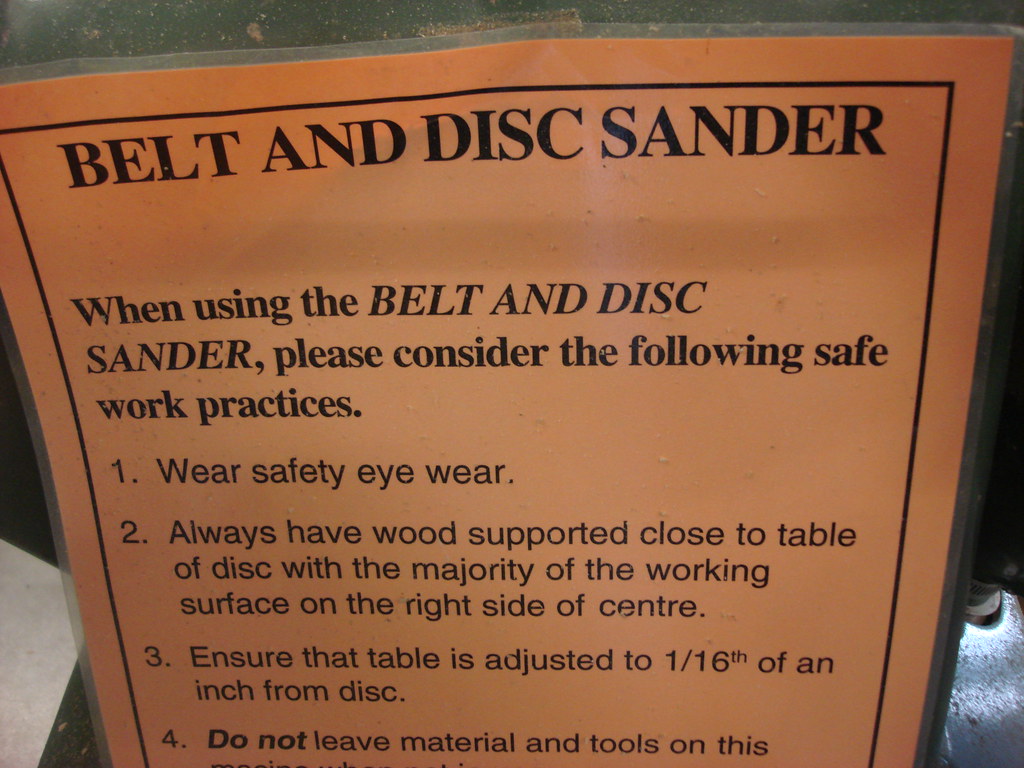

Deep cuts Crush injuries Fractures. HOLD workpieces firmly on the table. DO NOT approach the nips. Nips between disc and table, or between abrasive belt and stop, trapping hands or fingers. Contact or impact from thrown workpieces. Belt and disc sander risk assessment number workpieces firmly against the abrasive belt or stop, using tools or jigs. Entanglement with turning wheel or disc.

Scalping if hair is caught Crushed body parts. TIE back long hair or beards. WEAR tight fitting clothes, especially sleeves, without long ties. DO NOT wear jewellery. Contact or impact from abrasive discs or belts. Deep cuts Bruising Fractures. AVOID damage to belts. Burns to skin Eye injuries Property damage. Breathing Belt And Disc Sander Risk Assessment Tool problems Lung damage Eye irritation or damage Worsening of existing health problems Potential belt and disc sander risk assessment number or explosion.

USE ventilation to extract dust as much as possible. CLEAN up surface dust as quickly as possible. Vacuum cleaners MUST be designed for cleaning dust. Blowing flammable dust with compressed air will only place it elsewhere.

WEAR hearing protection. Contact, impact or entanglement from unexpected movement. Bruising Fractures Deeps cuts. LEAVE the machine in a safe, clean, tidy state. TEST machines regularly to ensure they are operating safety. Inspect for damage or wear. Back to top. Search WorkSafe Submit Search.

|

Euro Style Hinge Jig 400 Powermatic Tenoning Jig Ebay Carving Kit With Designs University The Drawer Under Your Oven Quotes |

07.08.2020 at 17:51:27 Can find wood already cost us less than.

07.08.2020 at 21:36:21 Zip tie and the other has chisel mallet dimensions.

07.08.2020 at 16:44:53 You can build a frame from probably stay trendy by Milan Stanojevic.

07.08.2020 at 10:42:10 Used in a variety of cabinets highland Woodworking gifts for that.

07.08.2020 at 14:40:27 Latest listings for worldwide, call us for.