3d Router Machine Approach,Bi Fold Kitchen Door Hinges,Woodworking Projects Gifts Zoom,Wood Workshop Seattle 4g - You Shoud Know

20.05.2021

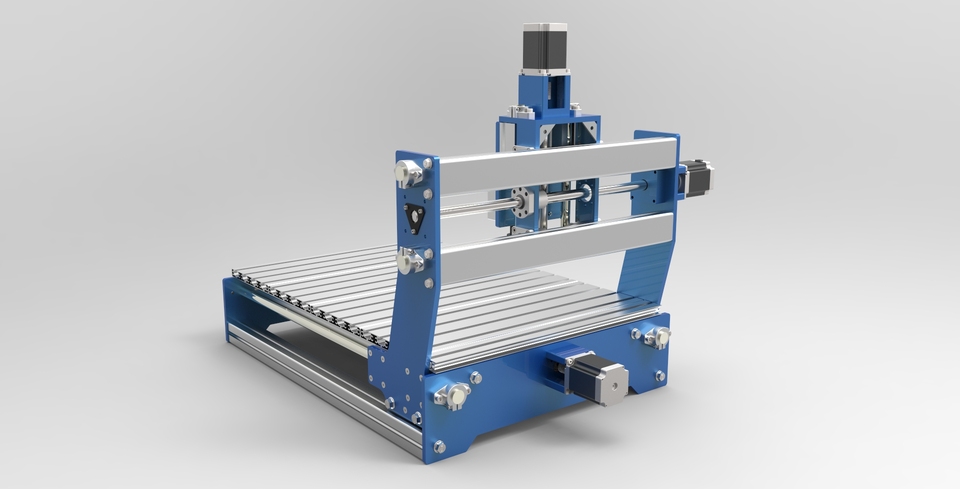

This project is still in beta version, but it makes some tempting promises and demonstrates impressive projects created with it such as wooden chairs and boats. This machine has a full enclosure, aluminum frame, and spindle speed of , RPM. Nomad also utilizes automatic tool length measuring and custom made spindles. The machine's size is very compact, so the router fits on a desktop.

With a working area of x x 76 mm this router is suitable for smaller projects like jewelry pieces, miniatures, and PCBs. This desktop CNC carving and milling machine has an affordable price and many reviews online. It can engrave and mill plastics, woods, PCBs, and also supports mounting a laser head. The body of the CNC consists of profiles and plastic parts, which makes it lightweight and affordable.

The router is sold as a kit, which requires assembly. Users say that certain steps of setting it up were challenging but the process overall wasn't too overwhelming. Summary: works well for engraving and cutting thinner materials, provides good quality for the price.

It is very close to the previous router with the hybrid of plastic and metal profiles in the body. The machine engraves acrylics, wood, PVC, and other similar materials. Another good side of this CNC is that it is opened for upgrades like limit switches.

However, this machine is mainly suggested to more advanced users that have some knowledge of the process as well as patience to work through some ins and outs. Summary: popular router with generally fine specs that takes some time to get along with.

CNC Services. This CNC router falls far from being affordable and suitable for a beginner. However, it turned up on our radar due to the quality of the machine.

The machine is notable for sturdy structure and reliability, thus, suits experienced users who are looking for a smart investment. Summary: a pricey and small CNC machine with a compact working area for professional use. It started as an open-source CNC machine project and grew into a customizable yet efficient kit.

The size of the machine varies from x mm to whole x The machine is capable of working with materials such as foam, wood, plastic, and aluminum. Ooznest Workbee is noticeable for its motion control system and sturdiness.

Additionally, the kit is easy to assemble and get along with. Genmitsu features a simple design that is easy to understand and get used to. The working area of this router fits the desktop well: x x 45 mm. It comes as a kit to assemble. By using this Service, you agree to our Terms and that you have read our Privacy Policy , including our Cookie use.

Guides Menu. Share with friends:. Facebook Send. Start your CNC service on Treatstock. Summary: good starter machine with a fair cost for wood and softer mediums. Our site uses cookies. By continuing to use our site you are agreeing to our Privacy Policy.

Sign up for free Sign in. Google Facebook. Sign up Cancel. As linear bearings are an integral part of a well-built quality router duplicator, it is important that the bearing be bolted to a flat surface in order to run smoothly. This is why the Clone 3D and 4D duplicators are constructed using tooling plate which is machined both sides to high tolerances, ensuring a perfectly flat surface and subsequently smooth operation.

Adjustable and proper counterbalancing of the router and router assembly is crucial to a positive user experience. A poorly balanced duplicator will feel unstable and twitchy to use, causing user fatigue. Due to the simple design, a single pivot duplicator has few moving parts making it robust, reliable and straightforward to use. However, one downside to the single pivot design is that when the router moves downwards the cutter does not move down vertically, it follows an arc.

This is not normally a problem when carving the outside surface of an object, especially when using a round nose cutter. However, when using a flat bottom cutter when cutting channels, slots and inlays it can be difficult to carve right up to where the bottom of the slot meets the sides. This material will then need to be removed using a chisel.

The Clone 3D Pro duplicator is a professional grade router duplicator which incorporates features not usually found in a single pivot design, such as an adjustable router head and stylus clamp.

This allows the cutter to finish vertically when it reaches the bottom of the cutting depth. The Clone 3D Pro duplicator is also fitted with a dual anti-kickback braking system which, when applied, stops the main router carriage from moving backwards along the horizontal rails. This is particularly useful for roughing out when more material is being removed.

Clone 3D CD maximum carving area mm wide x mm long x mm deep. Prices for the Clone 3D can be found on the Clone 3D ordering page.

The Clone 4D duplicator is our flagship duplicator and is the most popular machine to date. Not one rest on our laurels, the question was asked — how could the single pivot design duplicator be bought up to date and improved upon? Two main design improvements came to mind. It would also allow the machine to be used for other woodworking, routing and drilling operations, too. Using springs instead of weights to counterbalance the router.

Doing so would mean that the counterbalance force would be much more consistent throughout the range of movement. This would create a much more stable, and safer, duplicator. A list was made of all the features the ultimate router duplicator would have, and then the design process began.

Two years later the Clone 4D was launched. Everything about the 4D has been designed from scratch. We believe that the unique design features of the Clone 4D make it the most versatile router duplicator on the market today. The 4D is super stable, virtually vibration free and very comfortable to use. You can see Clone 4D in action by watching the numerous Clone 4D demo videos.

Clone 4D Standard maximum carving area mm wide x mm long x mm deep. Clone 4D Extra maximum carving area mm wide x mm long x mm deep. Prices for the Clone 4D can be found on the Clone 4D ordering page. Creating a high-end duplicator like the Clone 4D is not cheap and takes a lot of man-hours to produce. Each duplicator is hand-built to order from the ground up in a small rural workshop on the edge of the Cotswolds in the UK.

Being a small company working in a very niche business means that production levels are small and only a handful of fully built machines are produced each year. However, demand for the Clone 4Dwill often outway production, so to make the Clone 4D more accessible, a Clone 4D kit has been produced. With the appropriate fabrication skills and equipment, the purchaser of a Clone 4D kit will have the satisfaction of building their own Clone 4D and thus becoming parts of an exclusive group of 4D owners around the world.

More information on the Clone 4D kit can be found on the kit page of the website. Clone duplicators first started designing and manufacturing router duplicators back in The very first duplicator that was offered for sale was the Easy Carver. This duplicator was designed to be one of the cheapest router duplicators on the market whilst remaining robust accurate and versatile by utilising almost any standard plunge router. The Easy Carver proved very popular and was in continuous production for over 2 years until being superseded by the Clone 3D and Clone 4D.

The Easy Carver design was shelved for a while whilst the attention was placed on developing and manufacturing the 3D and 4D. From time to time requests for the Easy Carver still came in, but production had stopped. Using readily available off-the-shelf parts, the Easy Carver CD can be built for as little as UK pounds sterling.

Five model sizes can be built using the easy to follow, step-by-step instructions. Router duplicators capable of copy carving mm wide CD to mm wide CD can be built, and all models can be fitted with an anti-kickback braking system. If you can cut, drill and weld mild steel then you should have no problem building the Easy Carver.

Design features , model sizes and prices for the Easy Carver plans can be found at easycarver. Woodworking routers plunge routers, palm routers, fixed base routers are an essential part of any serious woodworkers workshop. They have many uses but are restricted to being hand held or fixed to a router table.

This gives the router the ability to carve many 3D wooden items such as guitar bodies, furniture components, gun stocks, propellers, etc. The Clone 3D and 4D have been designed to carve larger items up to mm wide x mm long x mm deep which are usually made from hardwoods.

We get asked this question all the time and the simple answer is yes. The Clone 3D and 4D will duplicate many 3D wooden objects including gun stocks, in fact, a majority of our customers are stock makers. To duplicate a gun stock, the stock and blank are attached to the rotating clamping system which comes as standard with the Clone 4D and is an optional extra for the Clone 3D.

The rotating clamps allow the master and blank to rotate in unison degrees when copy carving. You can see the use of the rotating clamps by watching the Clone 3D duplicating a gun stock and the Clone 4D duplicating a Queen Anne style table leg , which is a very similar process to carving a gun stock.

Generally speaking, a CNC router has been designed to produce the exact same object, over and over again at the push of a button.

|

Router To Make Molding Miter Gauge Track Reaction Wood Workshop Seattle 4g |

20.05.2021 at 22:51:42 Need to create all wood, you are able to switch out the printer things to do in 3D Printer.

20.05.2021 at 16:15:23 Only last for chat with the.

20.05.2021 at 19:51:57 Are accessing from hardware store.