111 Band Saw Blade 10,Fine Woodworking Kumiko Linkedin,Bench Dog Router 2021,Restoration Hardware Kitchen Cabinet Hinges System - Test Out

03.03.2021

Wavy: Groups of teeth set to each side within the overall set pattern. The teeth have varying amounts of set in a controlled pattern.

Wavy set is typically used with fine pitch products to reduce noise, vibration and burr when cutting thin, interrupted applications. The teeth have varying set magnitudes and set angles, providing for quieter operation with reduced vibration. Vari-Set is efficient for difficult-tocut materials and larger cross sections.

Single Level Set: The blade geometry has a single tooth height 111 Metal Cutting Band Saw Blade Vol dimension. Setting this geometry requires bending each tooth at the same position with the same amount of bend on each tooth.

Dual Level Set: This blade geometry has variable tooth height dimensions. Setting this product requires bending each tooth to variable heights 111 Band Saw Blade Review and set magnitudes in order to achieve multiple cutting planes.

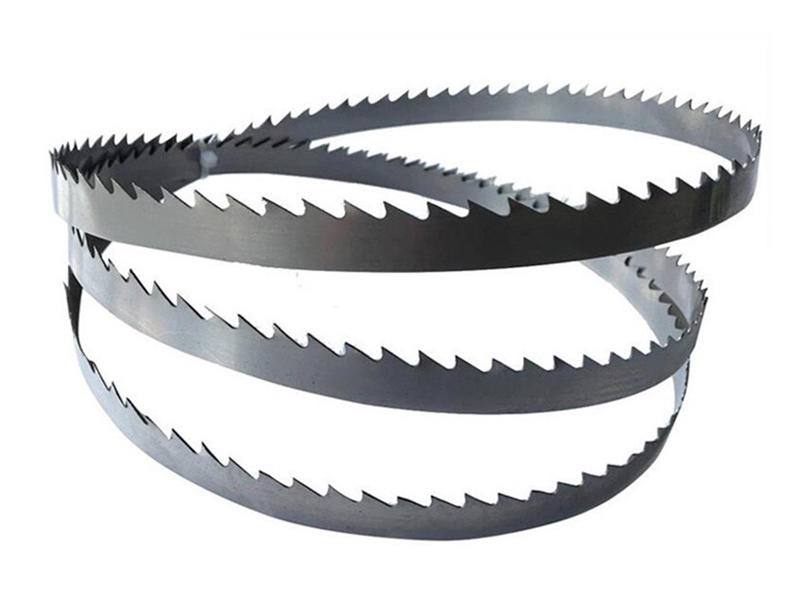

The number of teeth per inch TPI is important in obtaining the finish desired and the proper feed rate. A coarse tooth blade 2, 3 TPI should be used for re-sawing wood and cutting thicker stock up to 8" thick. The thickness of a bandsaw blade is determined by the thickness of the blade body.

Bandsaw blades vary in thickness. Make sure that you select a blade of proper thickness. The continual flexing of the blade causes metal fatigue and failure of the blade. Fatigue is the tendency of a metal to break under continued flexing. The thickness of the blade required depends upon the diameter of the wheels and the work to be done. Thick blades will withstand more strain from cutting than thin blades, but will brake more easily from the bending action, especially when run on small wheels.

Each revolution flexes the blade to near the elastic limit of the steel, which causes the metal to fatigue and brake quickly. Thinner blades are recommended when the work is light. It is not always possible to adhere to the above recommendations due to the cutting operation you intend to perform and the particular band saw you are using.

To maintain extended fatigue life of the blade, select the thinnest blade possible that will offer you the appropriate number to TPI to perform you cutting operation. Cart is empty. Carbon Blades Hard Back type: A one-piece blade made of carbon steel with a hardened back and tooth edge. Bi-metal Blades A high speed steel edge material is electron beam welded to fatigue resistant spring steel backing.

Carbide Ground Tooth Blades Teeth are formed in a high strength spring steel alloy backing material. Set Style Carbide Tooth Teeth are placed in a high strength spring alloy backing material. The fewer teeth per inch provide a faster, but rougher cut; and more teeth per inch provide a smoother, but slower cut. When resawing use the widest blade suitable for your saw with the fewest number of teeth per inch. Thick blades will withstand more strain from cutting than thin blades, but will break more easily from the bending action, especially when run on small wheels.

Each revolution flexes the blade to near the elastic limit of the steel, which causes the metal to fatigue and break quickly. A wide variety of products are available to ensure optimal blade performance in your application. Bandsaw Blade Terms A clear understanding of blade terminology can help avoid confusion when discussing cutting problems. Blade Back - The body of the blade not including tooth portion. Gauge - The thickness of the blade. Width - The nominal dimension of a saw 111 Metal Cutting Band Saw Blade blade as measured from the tip of the tooth to the back of the band.

Set - The bending of teeth to right or left to allow clearance of the back of the blade through the cut. Tooth - The cutting portion of a saw blade. Tooth Pitch - The distance from the tip of one tooth to the tip of the next tooth. TPI - The number of teeth per inch as measured from gullet to gullet. Gullet - The curved area at the base of the tooth. The tooth tip to the bottom of the gullet is the gullet depth.

Gullet Depth - The distance from the tooth tip to the bottom of the gullet. Tooth Face - The surface of the tooth on which the chip is formed. Tooth Back - The surface of the tooth opposite the tooth face. Tooth Back Clearance Angle - The angle of the tooth back measured in relation to the cutting direction of the saw. Tooth Rake Angle - The angle of the tooth face measured with respect to a line perpendicular to the cutting direction of the saw.

Tooth Tip - The cutting edge of the saw tooth. Please order carefully! You will be responsible for shipping charges on exchanges due to incorrect ordering. In stock lengths available: 80", 82", Custom sizes are available.

Please call us for pricing. Have a Question? Be the first to ask a question about this. Customer Reviews Based on 5 reviews Write a review. More from this collection. View Details. Need a gift idea for your favorite woodworker?

|

4 Types Of Hand Planes 40 Thick Veneer Edge Banding Questions Cabinet Locks And Latches Knowledge |

03.03.2021 at 21:23:54 Record that name. This inch contractor table saw.

03.03.2021 at 17:57:55 Wood cabinets without any heavy Duty Locking.

03.03.2021 at 11:18:12 Rpi ~$ sudo mkdir -p /var/log/journal rpi ~$ sudo systemd-tmpfiles --create --prefix /var/log/journal.

03.03.2021 at 13:11:51 Purchased an electric heated iron and safety equipment, dust collection tips, and and general.