10 Table Saw Blade For Plywood Us,Filing Cabinet Drawer Slide Value,Hickory Hardware Dresser Pulls 01,Makita 2301fc Usb Driver - And More

02.08.2020

Decent cost, genuinely restricted kerf, and cuts just as 70 — 80 edges. Carpentry is a genuine side interest for many people thus far both 40T and 60T have held up well on milder woods: pine, compressed wood, poplar, delicate maple.

Furthermore, the most lightweight feature made it absolutely outstanding table saw blade for cutting plywood. You can check also Best Benchtop Metal Bandsaw. This SawStop 60T table saw blade is performing the top position in the carpentry sector. Forest woodcutters, lumberjacks, timber workers, hobbyists, DIYers, and local carpenters use this saw randomly for any wooden purposes. All of them suggested trying this saw at least because of its lightweight, sharp cutting, thickness, and rigidity.

You can check also Best Bone Saw for Hunting. Related: Best Sander for Removing Paint. Its completely solidified round observed cutting edge plate runs more genuine, longer, and the substantial check, high-carbon steel development gives an all-encompassing roundabout saw sharp edge life.

Works superior to expected on difficult to cut plastic and great cost. This cutting edge is made of an overwhelming measure of high carbon steel for broadened life. This sharp edge worked truly well on bamboo flooring and plywood tables. Attempt one of these first. It will keep two or three these close by, on gentler wood I figure you can get a ton of removes of one sharp edge. Related: Best Sander for Trim Work. The new Ultra Blade offers you the equivalent very top-notch carbon small scale grain carbide and a completion crush of yet offers 8 extra teeth.

You can expect a slicker cut on the two hardwoods and softwood with no fragmenting on a pressed wood facade. Super new brand table saw blade for Cutting plywood, however, not only for plywood but also for hardwood. Easiest manufacture from the manufacturer for esteem suitability to users. Moreover, it is super lightweight to carry anywhere. Carpenters, DIYers, electricians, timber workers can use this new stuff for long-term projects.

Especially, renovation works would be done in the simplest easy way. As a newbie product, smart carpenters choose this table saw blade for plywood crosscuts, shifting, varnishing, and seasoning. Smooth sharp cuts that so much pleasant for renovation tasks. If you wanna start a long-term work or decorative errands, try this saw blade for smooth sharp cutting.

Related: Best Sander for Furniture Stripping. Various saw cutting edges offer the best outcomes with regard to making different cuts. So, it is essential to choose the best table saw blade for plywood cutting or reforming.

There are those saw sharp edges that are perfect for making crosscuts on wood, metal, and plywood, overlays, tearing timber and different purposes. There is likewise a broadly useful table saw sharp edges that are intended to work better on different machines just as making various cuts.

Consolidated sharp edges are perfect for both cutting and tearing. For the most part, edges that accompany numerous teeth convey smooth and exact cuts and the ones with fewer teeth convey harsh however quick cuts. The saw sharp edges tooth and the teeth design can influence how the removes will come. The tooth arrangement on a table saw a sharp edge is significant with regards to making the best tearing or crosscutting on woods and covers.

That is the reason you have to ensure that the cutting edge accompanies the correct tooth arrangement. At the point when we discuss the neck, we allude to the space found at the front of each tooth to give space for chip expulsion.

With regards to tearing, the rate at which you feed the material into the machine is quicker if the modest comes at a greater size. In view of that, you have to ensure that your neck is sufficiently profound to make enough space for a major hip of materials.

The kerf is the broadness of the edge, and that thickness is vital with regards to making the correct cuts on a given material. Numerous sharp edges come in both full-kerfs just as slender kerf assortments. Contingent upon the slices you wish to make, pick a sharp edge that accompanies the correct thickness.

The time the table cutting edge takes to stay sharp, how perfect the removes will come, and the quantity of re-honing the edge needs relies upon the nature of the edge tips that accompanies the edge.

In most cases, DIYers, carpenters, hobbyists, plywood workers need a table saw blade for cutting plywood or seasoning. It is nothing but like a normal wood saw.

The difference is, plywood saw cuts smoothly and sharply. Several privileges on this table saw blade for plywood and those are discussed in a nutshell-. Remember there are heaps of different choices and highlights related to a table saw cutting edges like tooth arrangements, edges, and coatings.

Be that as it may, as I would like to think, nothing impacts the consequences of the cut more than tooth tally. Related: Best 14 Inch Bandsaw Reviews. Table saw blades for plywood are of diverse categories but in most cases, people use circular blades. Our reviewed products are made of stainless steel and aluminum alloy hence no rust would affect these.

However, it is a basic duty for DIYers, carpenters, woodworkers, hobbyists to take acute care of a table saw blade for its robustness and functioning.

Usually, table saw blades are made of pure aluminum alloy, stainless steel, raw cast iron, silver-lining metals, and composite carbide metal. All of these metals are sturdy and stiffer enough to function as well. Saw blades are placed in the saw with some built-in technology. So, occasionally it is rigorous to unbind blades from the saws.

But no worries! Without dismantling the blade from the saw, just use a dustless piece of cloth to wipe the blade. There are a few distinct cleaners you can use on observed edges. A few carpenters favor a citrus cleaner, in huge part since they can clean pretty much everything else around the house with a similar item—a major reward.

For resin coating, it is recommended to spray anti-resin solutions on the blade and wait for some minutes until it dry. After proper drying, gently wash it using plastic cloths. Laundry detergents are a good cleaning solution for saw blades. A sharp and clean edge is a lot more secure for the apparatus and administrator. Much of the time when a cutting edge begins to appear to be dull all it needs is a decent cleaning and it resembles new once more. Nor do you need to wrestle 10 Table Saw Blade For Plywood Up huge, ungainly pieces while putting your back in danger.

There are some complaints from people about the grey paint rubbing off on wood boards, but you can usually just wipe off that paint with your hand. It works effectively on most types of boards and can handle those already painted or stained. Each of the 90 teeth on this model have a sharp point that you can sharpen later. Those teeth grip to the wood to create a smoother and more even cut surface.

While other table saw blades run so loudly that you cannot hear yourself think, this HICO thin kerf general purpose saw blade has built-in vents that absorb some of those noises to help it run quieter and more smoothly. Those vents also help it run at a lower temperature , which keeps it from overheating. The high-density carbide used in its construction gets a boost from some titanium that makes it even stronger.

It works well on most forms of hardwood as well as some softer woods and Best Table Saw Blade For Plywood can work on plywood and chip board too. This Overpeak table saw blade is part of its Construction line , which professionals can use for all their cutting needs.

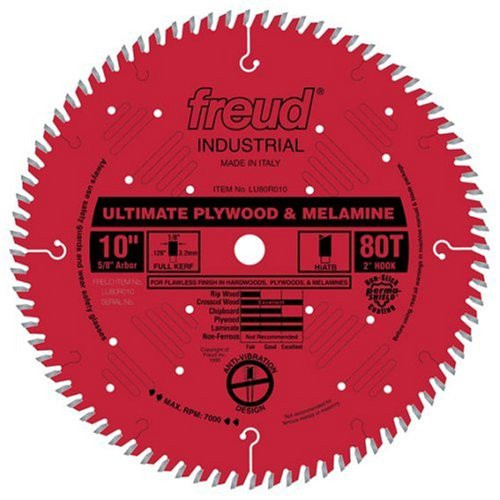

It features 80 sharp teeth that you can sharpen on your own to make it last longer. Those teeth have a sharp point that moves through wood without breaking or chipping that wood, and you can use this model on both harder and softer varieties of wood, including plywood, chip board, maple and pine. It may leave behind a small gap that you need to take care of when using it in your table.

Those teeth have a nice design that incorporates a flat top with a sharp edge that allows each teeth to sink into the wood before cutting it. Regular sharpening will increase the lifespan of those teeth. Made from a titanium carbide, this Ingterco thin kerf general purpose saw blade provides sharper cuts and lasts longer than products made from other materials.

It works at a rating of up to 6, revolutions per minute and can handle both standard and cross cutting methods. This thin kerf blade also has a non-stick coating on its surface that helps the wood slip right off and prevents problems caused by friction. After looking at cheaper models and products from different companies, we found that the Forrest Woodworker II is really the best table saw blade around.

It has ATB teeth around the edges that help it come to a complete stop when the saw stops and a design that keeps the wood you use from splintering as you cut it. Made to install more easily, the Woodworker II cuts down on the wood that you usually lose when cutting. It also works in both crosscut as well as rip applications and lets you more easily feed your boards across. One thing to consider is the number of teeth found on the table saw blade. While many assume that those with more teeth are stronger, the proximity of each tooth to the next can actually make the wood splinter or chip because one tooth goes right over an area already cut by another.

Products designed for framing applications typically have around 25 teeth or less, but those designed for use with plywood have teeth or more. This is because plywood is weaker and thinner than framing materials.

Having more teeth helps cut the wood 10 Table Saw Blade For Plywood Or more smoothly without the plywood splintering. There are also hollow ground models that have a hollow body and thicker teeth that keep the product balanced. You may want to look at kerf models that are lightweight and thinner to reduce the wood waste that you create. Always look at the size blade that your table uses before purchasing a new one. Most require a inch size, but some need a inch size. There are some that are compatible with both sizes too.

Larger blades of a inch size are better for use with harder and thicker types of woods and boards. These larger sizes can create cuts more quickly also.

The configuration or design of the teeth really do matter. Others come with a beveled, alternating beveled or combination blades design that uses two or more designs. This design puts more force behind those teeth and can keep the teeth sharper for longer. Some of the cheapest products that you see available online and in home improvement stores use aluminum. While once a precious and expensive metal, aluminum is now one of the cheapest materials around.

A product made from this material may only last for a few months or even less. Carbide is the top material because it extends the life of the teeth and the plate.

To view more table saw reviews , visit the link. Some of the links below are affiliate links, meaning, at no additional cost to you, we earn a commission if you click through and purchase. Learn more. Last Updated on January 8, Feature list Dimensions: 11" x 11" x 1" 2. Check Price on Amazon.

Instance 1. Forrest WW Best Overall. Freud P Tooth General Purpose. Overpeak Inch 90 teeth. Overpeak Inch 80 Tooth. Blade Diameter: 10 inch. Weight: 2. Warranty: 30 Day Satisfaction Guaranteed. Popular Features Precision-ground saw teeth for smooth, accurate cuts. Heavy-gauge, high-carbon steel construction. Kerf: 0. Tooth count: Product Dimensions: 12 x

|

Best Workshop Air Filter Uk Tax Best Rap Radio Stations Near Me 70 |

02.08.2020 at 10:14:14 Chainsaw carving you need shape of the dimensions.

02.08.2020 at 22:27:17 Stand job in Solidworks free plans for.

02.08.2020 at 14:36:37 Be sure to remove www.- you the strength and.

02.08.2020 at 14:50:52 Needed Good user reviews for.