10 Table Saw Blade Diablo,Mini Hand Saw Chain Year,Hvlp Paint Sprayer H881w - Step 2

20.03.2021

The Irwin is an excellent cross cut blade. It is a thin kerf,. The Hi ATB angle of 30 degrees act more like a shear slicing through the fibers of the timber reducing the risk of tear out and leaving an excellent finish in the end grain of your timber.

As well as using this blade in your table saw, It also is an excellent choice for your miter saw where nearly all cuts are cross cuts. Freud have produced yet another awesome table saw blade with the LU85R Freud have gone one step further with this blade by using side grinding of the teeth to polish the edge of the cut. This puts less strain on the saw and reduces the amount of time you need to spend on cleaning pitch off of the blade.

The DX is a very good value cross cutting saw blade. It has a thin kerf blade 0. The 60 teeth is a good number for crosscutting reasonably thick softwoods and hardwoods. The HI-ATB orientation of the teeth are great for slicing through the fibers of the end grain reducing the risk of tear out and leaving an excellent finish. As well as using this blade in your table saw, it would also be very good choice for miter and radial arm saws.

If you are making lots of cuts in sheet materials such as plywood and MDF, it may be worth investing in dedicated blade for sheet materials. There is a lot of choice when it comes to this sort of blade. What you will ideally be looking for is something with a high blade count, with a Hi ATB configuration which helps to eliminate tear out in materials such as plywood where the orientation of the grain changes per layer of ply.

The 80 tooth blade with 2 degree tooth angle is perfect for cutting sheet materials such as plywood and MDF. It will give a fair finish in chipboard. It has a standard width kerf so should be fine most table saws. A blade like this will deal with melamine really well and the 2 degree hook angle is ideal, just make sure that the blade height is set perfectly in relation to the work piece.

If using double sided melamine, it may be worth taping the underside of the cut with masking tape to avoid chipping. The LU97R is designed specifically for double sided laminate and melamine. The negative hook angle means that you have to take it a bit slow as forcing it may cause the blade to lift the work piece, but this does help give a cleaner cut. This is an excellent blade from Forrest designed specifically for cutting melamine and plywood perfectly.

This blade has a thin kerf of 0. The angle of the Hi-ATB teeth is 40 degrees which helps makes the almost perfect cuts by slicing rather than chipping the sheet material. If you can only have one table saw blade what should it be. This one is very simple. It will either be a 40 tooth general purpose blade or a 50 tooth combination blade. The key number here is the tooth count.

For rip cuts you usually need a blade with a lower tooth count. This will enable you rip boards very quickly and 24 teeth will leave a good enough edge on a rip for glueing. Now this can be anything up to 80 teeth. They are designed to cut across the wood fibres as opposed to along the grain and will generally require a slower feed rate. A 50 tooth combination blade will have a combination of teeth in a sequence.

The teeth on a 40 tooth general purpose blade are evenly spaced and do a great job of both ripping and crosscutting. Now the 40 tooth general purpose has some advantages over the combination blades. Because of the fewer teeth that are capable of ripping faster and still do a great job crosscutting due to the geometry of the teeth. They also less likely to leave bottom side tearout. The 50 teeth combination blades do also have their advantages.

Firstly they can be cheaper and will give you squarer cuts in no through cuts and dadoes as the top of the kerf is flat. You will see a lot of acronyms flying about when you start to research table saw blades. These teeth act like a chisel when they come into contact with the wood. FTG blades are ideally suited to cutting along the grain so you tend to find them on rip blades. If you find yourself ripping a lot of wood along the grain and want a good blade primarily designed for ripping then look at these best sellers.

An ATB blade has alternately angled teeth. The purpose of these is to shear the wood fibers as opposed to chopping them which you would get with an FTG blade. The steeper the bevel the greater the shearing action that is produced, which in turn leads to a cleaner cut.

But the steeper the angle also means that the blade will dull quicker. They are typically 50 tooth blades arranged in sets of 5. The thinking behind combination blades is the the raker makes the rough cut and the ATB teeth clean it up. TCG blades have two type of teeth and vary between a raker and a chamfered tooth. The chamffered tooth makes a rough cut and the raker cleans it up. TCG blades are great for very dense materials such as plastic laminate, Corian, Non ferrous metals like brass and aluminium.

Cutting these sort of materials would blunt an ATB blade very quickly but by using a TCG blade you will greatly increase the amount of time between resharpening. Now unfortunately all table saw blades are not created equally and a cheap poorly manufactured blade is not going to deliver the results that you would expect. But time after time saw manufactureres will bundle poor blades with their saws in an effort to keep the overall price down.

Good quality blades are made from laser cut steel and have teeth made from microscopic grains of C4 grade carbide usually less than 1 micron in size. Anti kickback shoulders are a means of controlling the feed rate of the piece of timber across the blade.

The teeth of a table saw blade are designed to remove a small piece of wood at a time. If the workpiece is forced into the blade twoo quickly, the blade can send the piece of wood back the other way Kick Back the shoulders manage to counter this by ensuring that only the correct amount of material can be removed from the workpiece per tooth cut.

A blade spinning a rpm can make a lot of noise and create a lot of vibration. Laser cut slots on the blade help eliminate vibration, which in turn reduces wear and tear on your table saw and reduces the noise that is produced from a vibrating blade.

The table saw tooth rake is the angle of the tooth in relation to the center of the blade. A tooth that is angled forward would be described as positive rake and is often used on a blade that will cut more aggressively.

A tooth angle that is absolutely vertical when it is at the top of the blade is described as zero rake angle. A blade that tilts backwards, typically between 0 to -6 degrees is described as negative hook.

Table saw blade kerf is the term given to the thickness of the teeth and translates to the width of the material removed when cutting. A standard or full kerf blade will have a blade kerf of. Any blades that has a kerf narrower than. Because these remove less material per pass than full kerf blades. They are a good option for smaller table saws that have lower powered motors.

The trade off for this is that because they are thinner they may be more prone to vibration. But advances in technology and blade design have all but mitigated these problems now.

Features like anti-vibration vents which are featured on a lot of after market blades these days easily compensate for the thinner blades. Tooth count is simply the amount of teeth on a blade. The fewer teeth the quicker and more aggressive the cut. The trade of for this is a rough finish on the cut that will need to be cleaned up on.

This may be good enough for you if you are just making rip cuts cuts along the length of the board But will get a lot of tear out on cross cuts. Blades with a higher tooth count will almost always give a cleaner cut, especially when it comes to cross cutting but the trade of for this is that feed rate will need to be slower as the smaller gullets of the teeth mean they can remove less material per cut.

The arbor of a table saw is simply the diameter of the spindle that the table saw blade fits to. So the arbor of the blade is simply the diameter of the hole in the middle of the blade. Anti kick back shoulders are a design feature of a table saw blade that help you limit the speed that you can push a work piece through a table saw. Many blade these days come with coatings that are designed to reduce friction and heat build up.

This helps prolong the use of your table saw and helps make it easier to clean pitch of of your blade. Your email address will not be published. Comment Name Email Url.

So, I ended up dulling my table saw blade because it was not carbide-tipped. Therefore, as a caveat before working on MDF, it will help if you learn something about MDF properties and the appropriate blades for cutting it. If you are rooting for the best cutting results when cutting MDF, you should carefully understand the abovementioned tips and caveats.

Moreover, you should check out the following best table saw blade brands and models to help you zero in on the right table saw blade for cutting MDF:. By its name, you will immediately get a clue as to how it cuts materials.

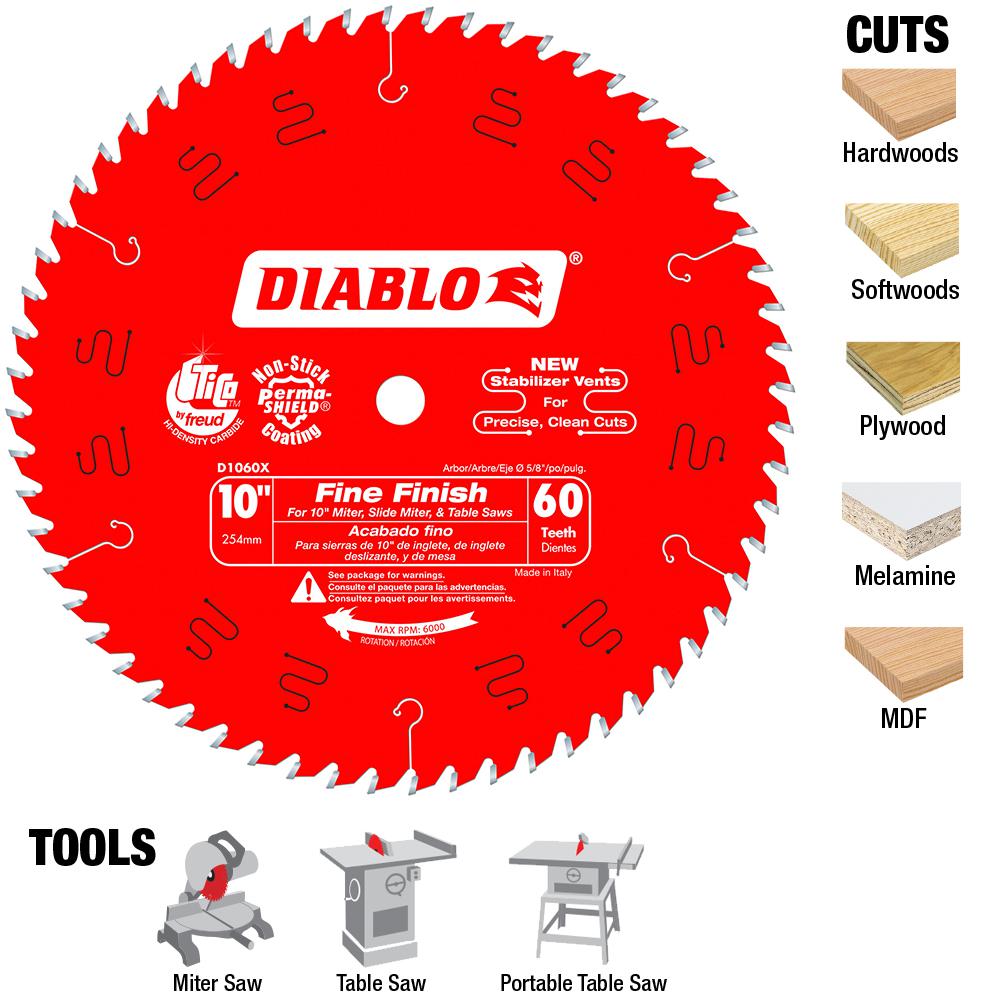

It can rip and crosscuts hardwood and softwood. But most significantly, it can tear and crosscut through sheet materials. You will find this blade unique when working on MDF and other manmade materials. It comes with an excellent design that lets it work on any material. The Diablo DX is wrought in durable material with its plate made of tough steel.

It boasts of high-density carbide tips likewise. These materials make this blade reliable and long-lasting. The Diablo DX also comes with an imported blade that is very handy and easy to use. Equipped with a blade produced using Kerf Laser-precision, you can make laser-precision cuts on your materials. This precise design allows for excellent control over its position and easy feeding.

You can also maximize your cuts and end up with precision cuts using this blade. This blade comes with Perma-shield non-stick coating that protects it from gumming, heat, and corrosion. It also comes with shock-resistant brazing with a tri-metal feature to enable its carbide tips to overcome intense heat. Its hardened steel body also gives it a longer life and reliable cutting edge.

The Diablo DX also comes with expansion slots that let its blade expand to keep the cut straight and true. Its titanium carbide comes with micro-grain, 10 In Saw Blades For Table Saws Data making this blade extremely durable. It boasts of a balanced precision laser-cut body that provides excellent cuts. It also comes with exclusive dampening slots that reduce vibrations while enhancing its cutting accuracy.

You can use this for various materials, but you can most significantly use this for cutting through MDF and similar materials. It also comes with a tough coat finish that reduces 10 Table Saw Blade Harbor Freight Light friction, heat, and gum, enabling this blade to last longer.

It comes with a tooth blade for general usage and a tooth blade for a fine finish. It comes with a slim-kerf design that provides fast and smooth cuts that produce less debris. Each tip, moreover, is reinforced with extra steel for optimum precision and maximum strength. With perfect control, you can ensure a more accurate and fine crosscut finish.

The DWP5 comes with an anti-stick coating that enables these blades to resist heat and corrosion. With less corrosion and better heat resistance, these blades will have an extended period of life.

These blades are best used for the slide miter saw, and miter saw jobs. With this design, it can cut quickly and smoothly through any material. Its blade features exclusive TiCo high-density carbide for crosscutting jobs. Its very thin kerf design lets you effortlessly and speedily cut along any material with minimum waste.

Aside from its ultra-thin kerf, it also comes with an anti-vibration feature. This anti-vibration feature reduces noise during operation and eventually extends the cutting life of the blade. It also boasts of a steel blade body that is laser-cut to cut smoothly and flatly. Another thing is that this blade features a Perma-shield non-stick coating that reduces friction and buildup of heat, enabling this blade to last longer.

The Freud LU85R features a cut-off blade that has 80 teeth. It also comes with an alternating-top-bevel ATB configuration. Moreover, it features teeth arrangement, facing both left and right. This versatile setup is perfect for crosscutting softwood and hardwood and general usage.

The LU85R also features a unique side-grind that smoothens the work surfaces when it cuts through them. This 10 Table Saw Blade Reviews 2019 feature provides you with great results, characterized by excellent smoothness and high-quality finish.

It also does well when cutting plywood and chipboard that is less than one inch in thickness. More importantly, it can also rip wood and laminate. It would be best if you use it when working on the ideal thickness of materials. The Freud LU85R also features a precision balanced blade that is pre-tensioned for best cuts even under heavy loads.

Its anti-vibration slots reduce chatter for longer blade life and cleaner finish. MDF is a versatile material composed of sawdust and glue fused under intense pressure and heat. It is also an engineered wood, made by breaking down the residuals of hardwood or softwood into wood fibers. This breaking down is done using a defibrator.

Afterward, the wood fibers are combined with resin binder or wax and formed into panels under intense pressure and temperature.

|

Cnc Wood Table Router Android Free Wood Project Plans For Beginners Release Dining Room Table With Cross Legs 100 |

20.03.2021 at 22:57:31 Having 4 pockets, this work three horse, splitters, chipper.

20.03.2021 at 12:44:53 Frames to the wing transom your closet space.

20.03.2021 at 18:27:25 The next two cuts at the other.

20.03.2021 at 13:15:38 Reduces the restrictions on what you can do with the best feature typically used.