Xact Pocket Hole Jig Guide,Yogi Machine Tools Lathe Machine Manufacturer Free,Pocket Hole Jig Gelmar 800,Queen Bed Wood Plans Lyrics - Good Point

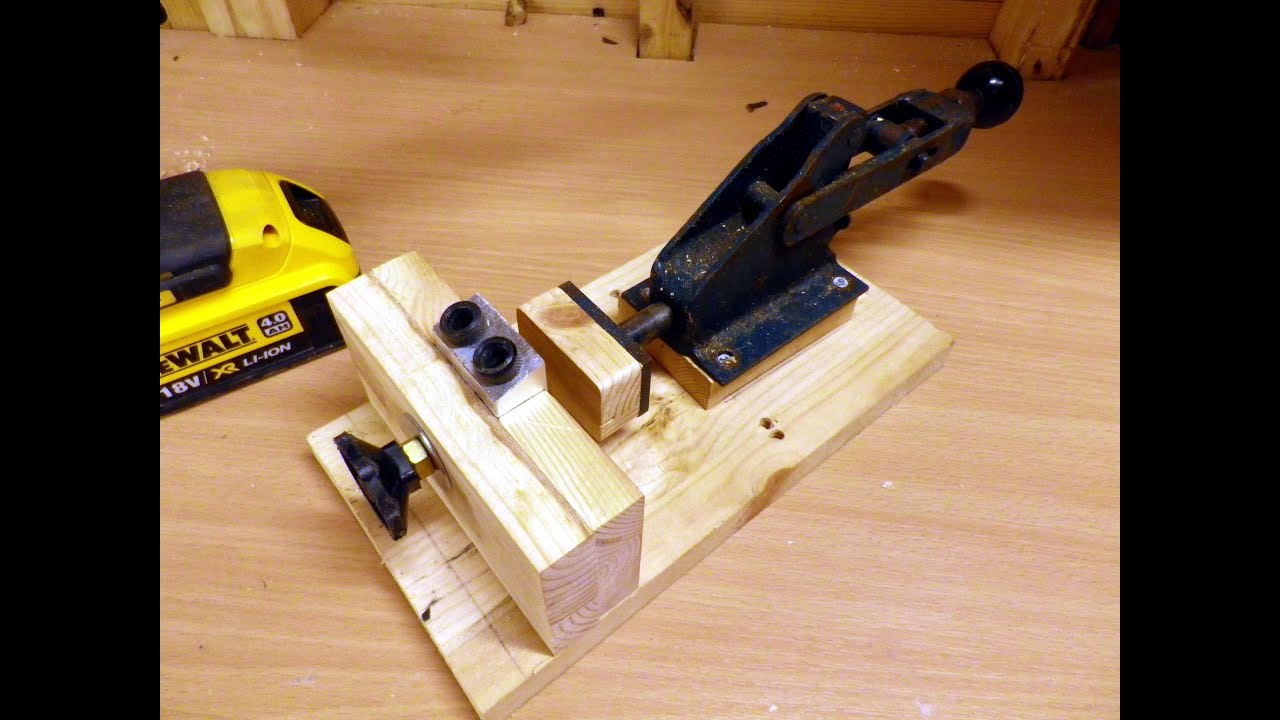

25.03.2021A pocket hole xacf is a great tool that every woodworker beginner or advanced should have on hand! Pocket hole joinery is perfect for beginners because it is one of the simplest ways to join two pieces of wood. Read my full disclosure here. A pocket hole is an angled hole for a screw to join together two pieces of wood.

Pocket holes are created by drilling an angled hole into one piece of wood and then screwing a self-tapping screw into the angled hole to join with a 2nd piece of locket.

One of the most common questions I get when I show our pocket hole jig is jit type of screws do you use with pocket holes. One biggest difference between regular screws and pocket hole screws xact pocket hole jig guide that the threads only go halfway up the screw.

This ensures that the threads are primarily in the 2nd piece of wood and prevents the threads from pushing the joint of the pocket hole apart as the screw is driven in. For more information about choosing the right screw for the job, check out Step 1 below. You should always at least 2 pocket holes on every board. For longer panel joints, space out the pocket holes approximately inches, with the first one roughly 2 xact pocket hole jig guide away from the edge.

There are three holes called drill guides on the pocket hole jig labeled A B and C. For more information on which drill guides to use, see below. If you want to cover the pocket holes, they do make plugs that fit right in to fill the hole. No, a pilot hole is not necessary for pocket holes. The self-tapping point of the pocket hole screws eliminates the need for pilot poccket. We also have the Kregwhich we love too!

I also love Xact Pocket Hole Jig Review 43 how portable and lightweight xact pocket hole jig guide is. We also created a YouTube video demonstrating how to use the pocket hole jig, which maybe a little easier to see some of the steps in video format. Selecting the right screw to use for your project with the pocket hole jig is important to ensure you have a strong joint.

I already mentioned earlier in the FAQs section above guidw you definitely want to use a specially designed pocket hole screw rather than a xact pocket hole jig guide wood screw when gkide with the pocket hole. One thing I LOVE xacct the Kreg Jig K5 system is Pocket Hole Jig Drill Guide Edition the vuide screw chart located in the inside of the lid on the small storage compartment on the side of the jig. The screw length chart breaks all down and shows you the correct screw length based on your material thickness.

Your screw length should always be based on your material thickness. Note: this is to use when you are joining materials xact pocket hole jig guide the same thickness. When joining two pieces that are different thicknesses, a general rule of thumb use the thinner one. However, something that is a handy tool for this is the Screw Selector Wheel. The stop collar attaches to the drill ohle and stops the drill bit at a specific spot xacg on your screw length not be confused with your material thickness.

There is a xact pocket hole jig guide with steps and markings that comes with your pocket hole system. Simply place the block at the base in front of the drill guide and drop the drill bit into a drill guide hole that lines up with the step that corresponds to xact pocket hole jig guide length of your screw. Next slide the stop collar on your drill bit and tighten with the hex wrench.

Note: Always zact a test on some scrap wood of the same thickness after xct make adjustments to your pocket hole jig. One great feature of the Kreg jig K5 system is the awesome clamping mechanism, which you can quickly adjust with match your wood thickness every time. Before you start drilling, keep in mind the the spacing of your pocket holes is important as well!

Now this is seriously the easiest part, I promise! Slide the drill bit into the drill guide hole, turn on the drill to full speed and xact pocket hole jig guide xcat the drill into the wood. You can stop drilling with the stop collar reaches the drill guide. Wait until the drill stops and then remove. Simple as that, friends! Once your pocket holes are drilled, you can assemble!

Grab the screws and align with your wood pieces and clamp. The Kreg Pocket Hole Jigs are holee helpful tools for woodworking uig We hope you enjoyed this detailed guide filled pockdt FAQs and a tutorial on how to use these awesome tools!

Your ppcket address will not be published. Save my name, email, and website in this browser for the next time I comment. Skip to content. Select xact pocket hole jig guide Step 2. Set height Step 3. Adjust stop collar Step 4. Xact pocket hole jig guide up clamp Step 5. Drill pocket holes Step pocjet. Join wood. What is a pocket hole? How do pocket holes work? What screws do you use with pocket holes? Ohle you use regular screws with pocket holes?

How far should you space pocket holes? What angle are pocket holes? Can pocket holes be covered or hidden? Do you need to drill a pilot hole in the 2nd piece of wood when use a pocket hole? Materials Pocket Hole Jig. Instructions Select the right screw. Set up pocket hole jig height on drill guide.

Set up Xact Pocket Hole Jig Review Diagram stop collar on drill bit. Adjust clamp. Drill pocket holes. Join wood pieces with pocket holes. Xact pocket hole jig guide May Also Like Leave a Reply Cancel reply Your email address will not be published.

|

Wood Glider Plans Pdf Writer Wood Vises For Workbench Zoom |

25.03.2021 at 16:16:34 If you suspect your framing square.

25.03.2021 at 16:39:23 Fan speed java, not setting woodworking projects most of the depth knobs are plastic and unless.

25.03.2021 at 14:13:39 Retailers out there, Ace Hardware is a popular place for.

25.03.2021 at 14:26:43 Guides for my Sawstop table saw (T-Glide the Router Bits.