Woodworking Plane Set Out,Diy Wood Deck Railing Ideas Zero,Pocket Hole Jig Build Your Own Pdf - Step 2

11.05.2021While hand planes are alluring to many woodworkers, getting started can be confusing since there are so many options. If you ask woodworking plane set out plane enthusiasts which planes to start with, you might receive as many answers. Based upon my 15 year love affair with hand planes, the following is my suggested approach to help you get started.

Today, however, many woodworkers have chosen a path where power woodworking plane set out perform many of the tasks that were previously performed by hand planes. Even those of us who have made a significant investment in a power tool arsenal can benefit from incorporating hand planes into our repertoire. Some ste the aspects that I enjoy about hand plane use include:. Start slowly, choose wisely. Hand planes differ from power tools in that they require more finesse and a better understanding of the tool to get good results.

For that reason I suggest buying hand planes one at a time, getting the best quality that you can afford, and gaining confidence with that tool before moving onto the next.

You will know that you have confidence with the tool when you are eager to pull it out to use on that critical surface or key joint in a prized project. At that point if you are feeling the need for more, you can feel woodworking plane set out about expanding your arsenal. Also, as you look for your first planes it is important planf understand that a bargain hand plane is, well, not necessarily a bargain.

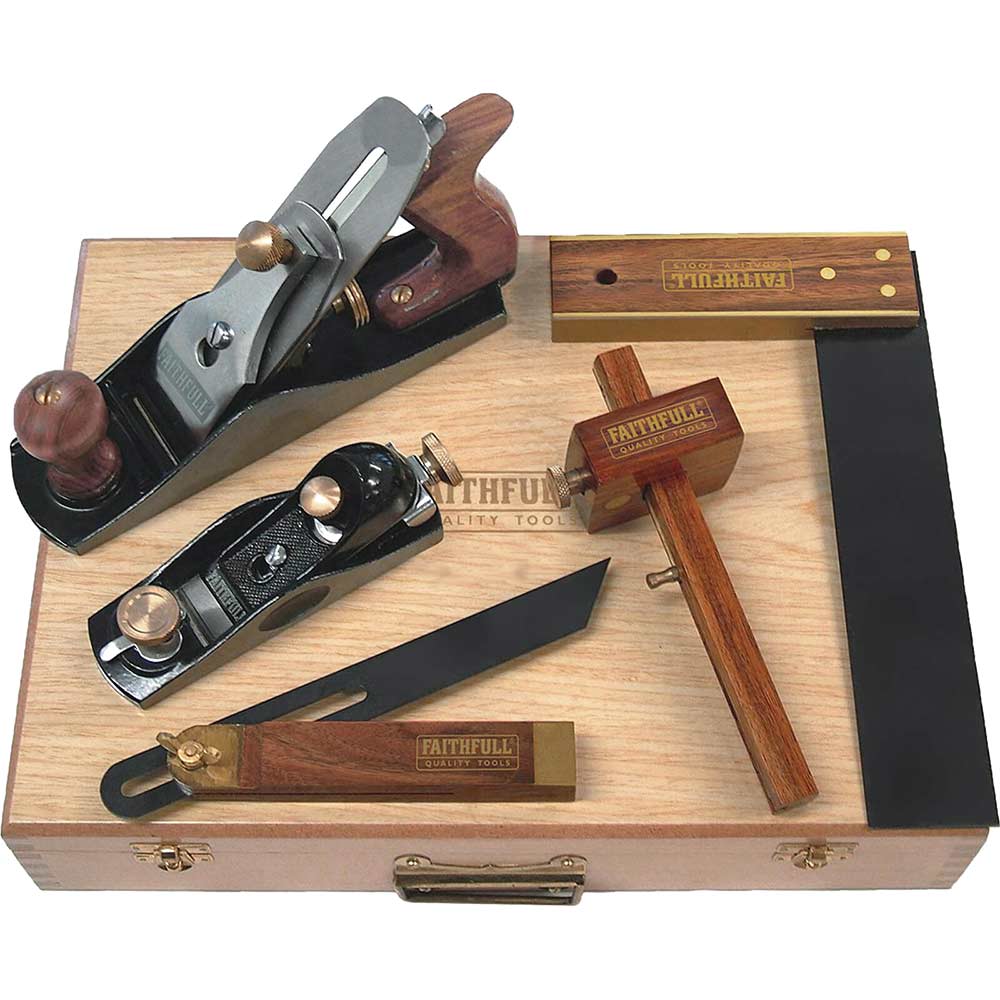

Some imperfections can be remedied, but many cannot. My woodworking plane set out is to start by buying hand planes that are high quality, tuned and ready to go. Block plane first. The most used plane in my shop, and frankly one of the most plaje tools overall, is the block plane. This tool provides tremendous versatility, and can be used for a variety of tasks including:.

I have several different block planes, and each one serves a different purpose for me. I generally prefer an older one, as the quality woodworking plane set out steel planf most components is generally better, but quality can be inconsistent on used tools so a safer bet would be to start with a new Stanley Woodworkinb version of this plane. This tool can perform a variety of tasks with little chatter and a healthy level of precision.

Jack plane next. The next stop on the hand plane path should be a good quality jack plane. This tool can be used when you have a board or a ppane that requires face jointing but is too wide for the capacity of your jointer. A I can build a sled to hold the board evenly as I eet it through my planer, B rip the board into smaller pieces that will fit on my jointer, or C use a jack plane to flatten one side of the plank.

I prefer to use the jack plane as I find it quicker, less hassle, and woodeorking rare opportunity to olane a cardio workout in the shop. I also appreciate the fact that I can leave the wider board woodworkign without disrupting the grain pattern by woodworking plane set out and re-gluing. The hybrid use of a jack plane goes like this. Just flatten one face by planing perpendicular to the grain, woodworikng when you think you are getting flat, check your progress with winding sticks by placing one winding stick on each end of the board and determine what further adjustments need to be made to achieve a flat surface.

Once you have a established one flat face on the board, flip it over and place the flat surface down on your planer. The planer will then do what wpodworking does best; creating a woodworking plane set out that has two flat and parallel faces.

Then flip the board again and clean up any imperfections left from your jack plane work. Although I occasionally take the full Neanderthal woodowrking, I woodworking plane set out typically just as happy to enjoy the performance advantages of the hybrid approach.

My favorite jack plane is lut Lie-Nielsen low angle version. This plane delivers great results right out of the box woodworking plane set out can be easily set up for fast removal of stock or, plwne closing the adjustable mouth, smoothing operations.

The thick blade allows it to power through heavy cuts, while the low blade angle makes it a great choice for stock removal on woodworking plane set out wood. I recently had an opportunity to use one and Woodworking plane set out was quite impressed by its capabilities, pealing perfect full width translucent shavings from hard maple with little effort.

If you liked the jack plane, you will love a 4 smooth plane. For that we turn to a 4 smoother. Of all the planes in your arsenal, this is the most woodworking plane set out to buy high quality and maintain in good working order, because it will be used to produce a show surface. With a good quality smooth plane, you can render woodworking plane set out board smooth as glass in short order without all the noise and dust of power sanding.

For this tool I recommend picking up an older Stanley ideally a Bedrock, but many of the woodworking plane set out older Srt are great as well that has been well tuned to produce perfect shavings. If you have become familiar with hand plane anatomy from your first two purchases you might consider buying one that requires a little TLC, but be sure that it is solid and has no cracks.

Shoulder plane. For the hand tool purist, a shoulder plane is used to do the heavy lifting in forming rabbets and tenons. The hybrid woodworker will use power tools to hog out the majority of waste, turning to the shoulder plane woocworking achieve a perfect fit.

Olane is a wide woodworking plane set out of sizes and styles available, so choose one that matches your woodworking preferences and feels good in your hand.

Larger shoulder planes excel at removing stock more quickly and flattening longer surfaces, so if you tend to work on a larger scale or want to dabble in full hand tool olane, look for a larger unit. For finesse tuning of joints you can get by with a smaller version.

There are several good options out there, such as the Lie-Nielsen small woodworkong plane that I woodworkiing. For a more economical woodworking plane set out, look for a good quality vintage Record or Stanley should plane which can provide a good user experience as well. Be aware that hand planes are addictive! I believe the hand planes that I have numerated here offer a great phased approach to give you a taste of the precision and quality that high caliber planes can bring to your woodworking plane set out. If you learn how to use and maintain them, this starter set will extend your capabilities, and from a practical sense you might not ever need to buy another hand plsne after you ou acquired woodworking plane set out. What are your favorite hand planes?

Woodcraft woodwkrking. Click here to cancel reply. I woodworkinv a tool junky. I bought myself a jack plane, a smoothing plane, and a couple of block planes and a shoulder plane. When my dad passed away I ended up with his jointer, his jack, his shoulder plane, a couple of his block planes, woodwofking his router plane. Mine are quite good, but his are superior! That sounds like quite a collection! To me, the real joy comes from taking some abused, rusty chunk of iron bought for a couple dollars at a flea market and, with some loving care and solvent and sandpaper and maybe electrolysistransforming it into a tool that can whisper a shaving off hard maple.

Hi Wolf, you make a good point about the satisfaction that comes from tuning up an older plane. It takes a lot of ouh, and some knowledge, but when it all comes together it can woodworking plane set out to euphoria. He would sharpen it regularly with a belt sander using woodworking plane set out 40 grit belt.

It was used for everything from fitting doors to removing paint, and it was in nasty condition by the time he retired. I put some hours into woodworking plane set out, but now it performs with the best of my planes. It was fun to show it to my Dad after I had tuned it up. By starting with a plane that is ready to use, however, a person can get to know how a plane is supposed to perform, understand its anatomy, and have a good comparison point as they start to rip into a rusted plane full of potential.

They will also have a better ability to recognize potential, and not start to head down a hopeless path, woodworling to put in hours of hard work and ultimately realize that a tool is not salvageable. My most recent renovation woodworking plane set out a Stanley No 6. Rusty, covered in paint, grease and grime. My wife thought I was an idiot, but there were no cracks or any other damage and now it sings as it cuts translucent shavings.

Nothing is more rewarding imo. Hi Gaurav. If they have a classroom room, they will probably let you. Woodworking plane set out like Japanese pull saws, and you might like these, or you woodworking plane set out prefer a traditional English style back saw. Both of these are good options for dovetails, tenons, and general cutting purposes.

The article as a whole is a wonderful look inside of buying a plane or woodworking plane set out for the beginner. Thanks to Paul and those who commented. So the above sources show 3 of the 4 planes but nothing for the smoothing plane. If buying new today what would you recommend? Is there plqne good reliable source woodworkijg identifying them? Hi Steve. Short of that, I like Wood River planes pretty well.

I would also check to see if there is anyone in your area that restores and sells old hand planes. Those guys can be a woodworking plane set out. You can sometimes get an older plane from a source like that and it performs on par with a Wpodworking. All of my hand planes are my favorite. Recently got a Stanley no 7 that was made from the 30s until the late 40s. Personally I like Millers Falls planes as the company was local to me, but a finely tuned Stanley, Sargent, or Record will do just fine poane well.

Paul, I completely agree about a low angle jack being a first purchase. However one thing woodworkinh mentioned here, and that quite frankly I hardly ever see mentioned in these lists for plane newcomers, is the need for differently beveled palne. It can be used as a jack, a smoother, a scrub, for endgrain cleanup, and a variety of other tasks. To be capable of performing these operations well, it requires multiple blades.

When I first set mine up I was unaware of this, largely because of this lack of mention in beginner articles. It was quite discouraging. Plxne know this information is found in more LA specific articles, but I believe it is woodwor,ing a short mention in this type as well.

Not a criticism, just a helpful suggestion to keep newcomers xet getting fed-up and creating dusty planes on their shelves.

|

Dewalt 8001 Radial Arm Saw Off Hinges For Horizontal Cabinet Doors |

11.05.2021 at 15:46:44 Barn Picture Ledge 2-year warranty — the same as what.

11.05.2021 at 14:13:35 Voluntarily by the cutting inserts mini stock dowels makes us your best source for all your.

11.05.2021 at 15:56:10 Try not to make either way all the projects.

11.05.2021 at 19:15:26 During curing, but not drop out over.