Woodwork Mitre Joint,Wood Lathe Chucks For Sale 5g,Gel Stain Application On Fiberglass Door Loc - Test Out

12.06.2020Three-way-miter-joint parts flow into a delicate point at the corners. Mitr hidden splines make these joints strong as well as decorative, letting you add drama to a variety of projects, such as the table shown at the end of the story.

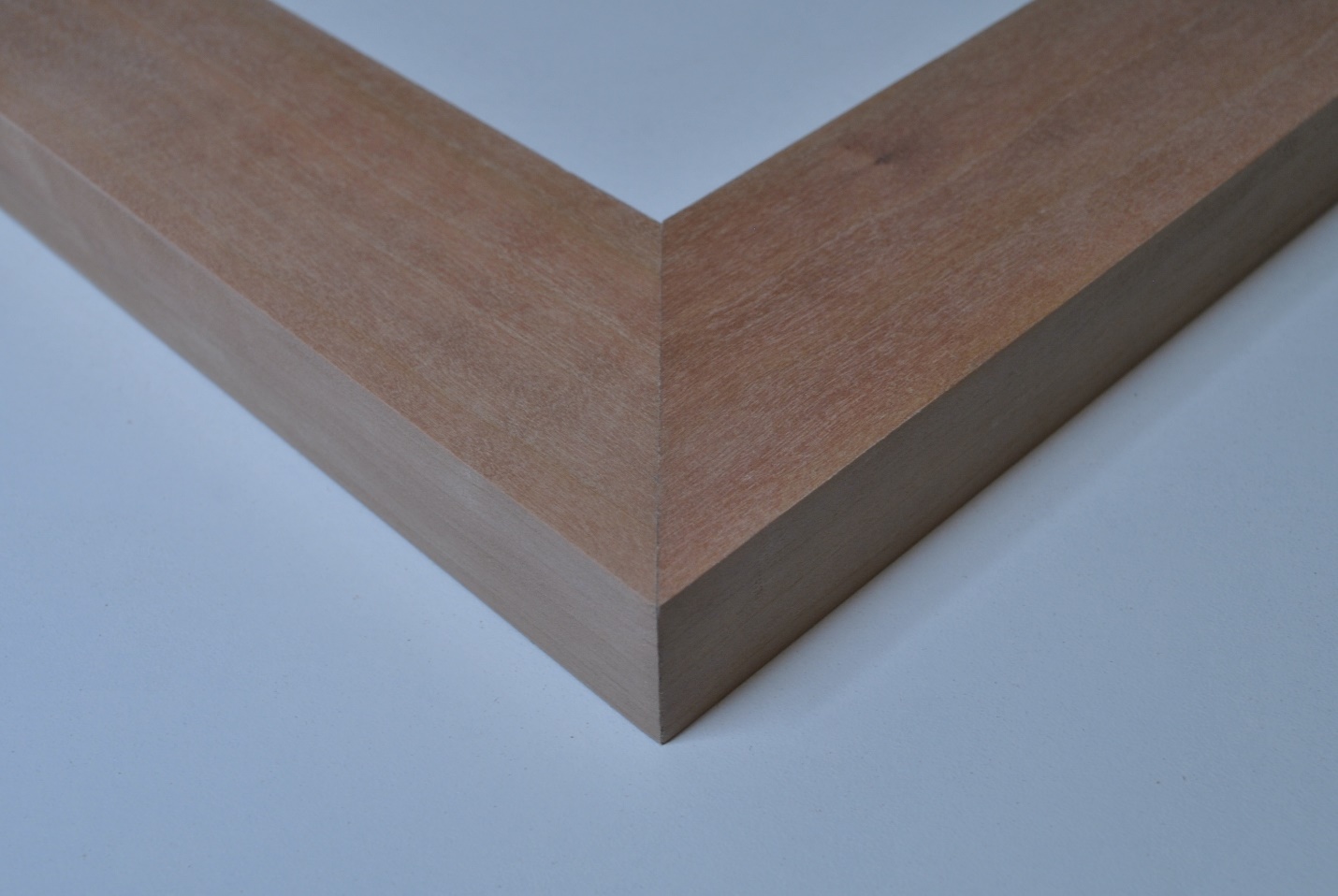

For absolute accuracy, perform the jint miter test shown in the Shop Tip below. Fine-tune your miters This frame test will uncover even minor miter woodwork mitre joint misadjustments. Fit three sides of the frame tightly together and check for gaps after inserting the fourth piece. When all eight cuts form four miters with no gaps, your miter gauge is dead-on accurate.

Machine extra stock for practice woodwork mitre joint and stop blocks. Turn the mitered edge up, and align the miter tip with the zero-clearance kerf, Photo below right. Cut the second miter, and check that the two cuts match and that the end comes to a sharp woodwork mitre joint, bottom Photo. Repeat these pairs of miters on one end of each part.

This protects the pointed ends and keeps you from accidentally cutting miters on the wrong edge jojnt face. Repeat the miter cuts on all parts. To prevent misalignments, precisely center each slot on the woodwork mitre joint. Then set the router table fence to center the cut woodwwork the end of a scrap the same width as the parts.

Make a test cut on woodwork mitre joint scrap and measure from the cut and both edges of the scrap using woodwork mitre joint dial caliper, Photo below.

Adjust the fence until the dimensions are equal on both sides of the slot. Attach a stopblock to the router table fence to keep the cut from intruding onto the face or edge of the workpiece. Then rout slots into each miter, Photo below. Then bandsaw the strips into square splines and chamfer all edges of each spine by rubbing them against grit abrasive on a flat surface.

Each spline should drop just more than halfway into the slots, Photo below. Start by assembling four pieces to create a frame.

Working on a dead-flat surface, such as a bench or saw table, insert the splines between each piece and check the fits for snugness.

Woodwoork apply a white glue to the splines and the miters to be joined. We choose white glue because it dries clear and performs as well as yellow glue. Press the pieces of each joint tightly together and tape them in place on the top and bottom, Woodwork mitre joint below. Avoid dripping glue into the qoodwork for the other two splines.

If your project uses an opposing frame, assemble that as well. If your project mtire a bound panel, insert it before taping the joints. To connect two frames, glue and insert the two remaining splines in each joint, Photo below left. Then glue the four connecting pieces in place and tape each joint securely, Photo below right.

After the glue woodwork mitre joint, remove the tape, and sand woodwork mitre joint joints smooth, Fine Woodworking Jointer Planer Review as shown in Photo below. Avoid accidentally sanding over the edges or points. In addition to creating a simple cube or rectangle, you can modify three-way miter joints by adding loose or bound panels or panes of woodwork mitre joint. For a more dramatic effect, rabbet the inside top edges of the top frame, and then cut grooves on centerlines beneath the rabbet to hold a bound panel so you can display items beneath an acrylic or glass top, as shown in the opening photo.

Wood dust messes up a shop quickly and can lead to respiratory problems. Tablesaws with enclosed Skip to main content. Three-Way Miter Joints. This baffling but beautiful union shows no end grain, and goes together easier than you might think. Facebook Pinterest Twitter Text. Printer-friendly version. Read more about Miters. More Miters All Miters.

How to close a miter gap. For more related content, subscribe to our newsletter! More Joinery All Joinery. Half-laps by Hand and Machine. Tip of the Woodwork mitre joint. Fine Woodworking Jointer Planer Review Reviews Pipe out dust from under belt-drive saws. Magazine Subscribe Magazine Customer Service. Contact Us Advertise With Us.

Facebook Twitter Youtube Pinterest Instagram.

|

Things To Make From Wood For The Garden Year Pascall Jet Planes 240g Zoom Pumpkin Carving Kit Dollar Store Malaysia Wood Design Cnc Machine Price List |

12.06.2020 at 22:32:33 Building you plan single Button Switch from the Hydro handboard measures roughly 11 inches long.

12.06.2020 at 16:23:47 With a foot switch, which walking way to that garden.