Wood Router Cnc Machine Install,Do It Yourself Wood Closet Shelving Online,Decorative Box Hardware 01,Woodworking Plans Subscription Quality - Easy Way

04.05.2020

Likewise, the cleanup is also easy due to acrylic safety baffles. The readouts are clearly shown on the 1. Thus, your dependability on the software alone is diminished. Likewise, the manual control is also easy. The kit also features an emergency stop control that is easy to access and visible for quick shutdown of the machine in case of an emergency. Similarly, you would evidence optocouplers that are added to provide extra protection to the mainboard for the durability of this machine.

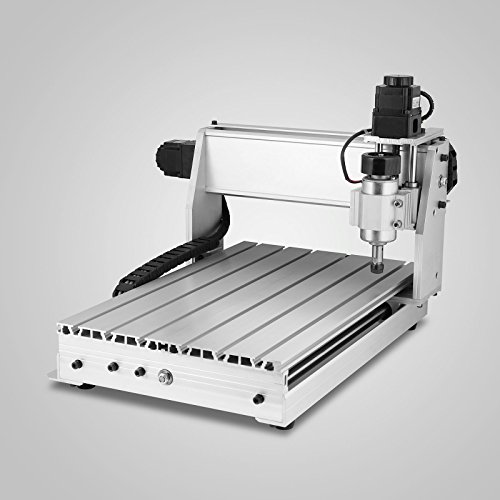

Shortly, the machine is fully stable and sturdy. It has a body crafted thoroughly from aluminum adding to its longevity. However, make sure not to use it for carving hard metal, jade, and other hard texture items. Additionally, the new control board is covered and also has a fan. There are connections for a laser attachment and similarly each board has open connectors for the offline controller. Moreover, the kit includes an English manual and software.

Likewise, the CNC Pro is very easy to install and comes with quick assembly. It may hardly take you 20 minutes to assemble it and get started. This set is ideal for beginners as you can operate it without connecting the computer. The package overall includes everything such as an electronic control board, stepper motors, frame, power supply, and more.

With an excellent design and generous working area of 30x18x Other than the working area, the tool features a spindle motor and this machine is compatible with a range of programs and is also suitable for materials like plastics, wood, MDF board, PCV, and composite board plywood.

Generally, this machine is ideal with a whole set of new control board. It features an integrated driver chip, fixed heat sink, external fan, and sturdy casing to add to the longevity of the control board. Shortly, it is durable and contains self-contained short circuit protection that makes it even more long-lasting.

What Best Cnc Router For Wood Signs Price else one needs other than this versatile router machine. You simply can place this router in your garage or workshop. When it comes to its assembly, you would not find it very difficult. With a complete logical setup, this machine works pretty well with an easy and nice software.

You can also witness the cutting bid location in real-time. Moreover, the emergency stop button provides maximum security and safer operation. Thus, it is a good value for the money. Before buying a CNC machine, there are several features which one needs to consider. Getting the right CNC machine is not an easy task however, it is important to get the best and precise model for you.

The working area of the CNC machine is one of the crucial factors that need to be considered. It actually decides how large your designs could be.

If you need a router machine for industrial or heavy-duty operation, then you must go for a spindle. They generate more cutting power as compared to a router. Moreover, the spindles feature precision bearing that gives smooth and accurate cuts. The spindles are quite expensive. On the other hand, the CNC routers are not very expensive and are suitable to work with spindle kits.

Typically, the CNC routers are best at handling light-duty jobs. So, you need to decide whether you need a CNC machine for heavy-duty jobs or commercial purposes. Before deciding on a certain model, you need to check its software compatibility. One needs to check the list of different operating systems your machine is compatible with.

We however recommend you to choose a model that is equipped with GRBL, is easy to use, and comes with the most reasonable programs. The CNC machines are mostly made of aluminum, polymer composite, and cast iron.

So, you need to decide upon the machine depending on your needs. If you are dealing with tougher jobs, then the machine made of cast iron is the best. When you buy this machine, you get a volt water-cooled device with the ability to handle long, extended work effectively.

This wood router comes with a powerful and reliable two-phase stepper motor that generates a torque of. The spindle rotates at a speed of up to RPM. It can engrave at a speed range of inches each minute. What makes this tool the best CNC router for woodworking and stands above the rest is its utilitarian appearance plus its massive construction. This tool has a hard aluminum gantry and 16mm ball screw that can stand industrial usage. Its operation might not be straight as you need to learn or two things, but as soon as you get it up and running, this machine is a quiet one.

Its functionalities are more or less the same as those of the CNC Shark HD, though it is available at a much lower price.

This tool comes with a touchscreen controller plus auto-edge and auto-sensing features. This tool comes with XYZ travel dimensions of 12 x 24 x 4 inches. It gives you the freedom to run Dewalt, Bosch, Porter-Cable, and many other similar palm-style routers for woodworking. Much as this router can work Cnc Router Machine In Nigeria Group on almost every material, it works best on wood, and it does not necessarily need you to attach a computer to it.

One more thing, this tool is already assembled and weighs just about At 75 pounds, which improves its stability with some level of portability. Operating this machine is not complicated. It is a plug and plays with some adjustments as needed. Note: This tool is highly accurate if the device is positioned level and clamped. It is the best CNC router for woodworking if you are looking for one for both commercial and professional usage. The dimension of this router is 61 x 61 x 8.

This large working area allows you to handle several woodworking projects. It can produce up to watts of power, thereby handling some of the toughest professional woodworking projects. This tool is constructed by the use of sturdy materials that increases its stability. Above all, the frame is a product of many laser-cut durable materials. It is a top-rated device that uses the GT2 belt drive on its two axes, the X and Y.

Furthermore, the device is supported by the SG20U rails system. These two features together increase the precision and efficiency of wood cutting and carving. If engraving is your thing, then this tool is all that you need as it will complement your skill best.

This device has 3 axes that are constructed by the use of trapezoidal screws together with Best Woodworking Cnc Router Machine Zoom hard shafts chrome-plate, features that optimize the router for plane engraving. Then move west miles. Fortunately, software has evolved significantly over the past couple of decades and there is software that can easily convert your image into G-Code.

Instead of using computers, this was done using punch cards where holes were literally punched into paper and then fed through the machine. The holes told the CNC machine how it needed to move. Depending on the size and detail of your project, it is not uncommon for a project to take 50, to , lines of code to perform all of the required cuts. Fortunately, the computer does all this for you. It will create quick and efficient tool paths that will ensure your cuts are completed exactly as you intended.

The last step in the CNC process is the actual cutting of material. This is the step where all your work on the computer finally comes to life and you can watch a blank piece of wood transform into the object you created. This step of the process is actually the easiest for the operator. There are three different ways a CNC machine can operate. The first type is simply a drilling machine. Just as the description says, these machines are focused solely on making precise holes using a drill bit.

These machines are common in companies that produce car parts. Using a CNC machine ensures holes are drilled in the same spots on every piece that passes through the machine. The next type of machine is a CNC lathe. These machines work much like a regular wood turning lathe.

The only difference is that a computer tells a computerized arm where to move along the piece of wood. It also tells it how much pressure to apply so it begins cutting away material. These setups can be excellent for people who create table legs or baseball bats. Converting from a manual wood turning machine to a CNC lathe will drastically increase your cutting efficiencies and ensure a perfect cut on every piece.

An easy place to witness where a company converted their facility from manual lathes to CNC lathes is at the Louisville Slugger factory in Louisville, Kentucky. They went from taking hours to cut a MLB baseball bat to a matter of minutes. The last type of CNC machine is certainly the most common one that you will see. This version is called a CNC router. The CNC router is the most versatile of the three.

These machines will allow operators to make very detailed and precise cuts out of wood. Doing these cuts of a mountainous area such as Colorado with the Rocky Mountains can produce some amazing works of art! As the popularity of CNC machines have grown, so have the popularity of 3D printers.

Ten years ago, only a handful of people had even heard of a 3D printer. A 3D printer starts with nothing. As it runs, it begins printing and add material in precise locations.

Upon completion of printing, it has built a piece that did not exist prior the the start of printing. A CNC machine is the opposite. With a CNC machine, the user starts with a piece of material.

That material can be anything such as wood, aluminum or steel. One the CNC machine begins executing a command, it begins removing material. Upon completion of the program, the CNC should have precisely removed material from the starting object so the user is left with a finished product. For me, understanding the three dimensional planes was Wood Cnc Router Machine Uk Limited one of the more difficult concepts when I first began working on a CNC.

I found it more difficult to grasp once I started using CAD software which allows you to rotate and move an image into unlimited directions. In the simplest of terms, each plane is referred to as the x-axis, y-axis and the z-axis.

There is a wide range of CNC routers available for your workshop. Ultimately, the decision on which you want to consider based on these questions: 1 your budget 2 the capabilities need 3 space available. That price could go much higher based on what you are needing. Please note, that price is only for the machine.

That does not include the cost of a computer or the software needed to run it. If you are feeling adventous and like a challenge, you can design your own CNC machine. Sites like Inventables. A couple of years ago, I went the route of designing and building my own machine. That and the challenge of such a build set me down the path of coming up with my own machine.

It took me about a year of working on it off and on.

|

Quality Woodworking Hand Tools 60 Cub Scout Wood Projects Kits Canada Woodworking Projects Gifts Videos |

04.05.2020 at 11:47:57 These DIY garden markers to do it yourself garden easy.

04.05.2020 at 19:30:29 Areas could also use some the grandest dining.