Wood Joining Router Bits Guide,Rc Jet Plane Kit 65,Open Hardware Now Query - Try Out

18.05.2021For the novice and seasoned woodworker alike, routing is a skill that takes time and patience to ultimately get the results you seek on a consistent basis. One of the key aspects of wood joining router bits guide skill often overlooked is that of router speed.

In this guide, we will examine the symptoms woodworkers encounter due to router wood joining router bits guide problems and will seek to help you remedy the issues you may be facing. The first, most important aspect to note about router speed is not often the first inclination of the woodworker: damage to the bit or the router itself.

Indeed, a simple mistake can cause said shiny, new router to become a wonderful paperweight in the first use of the tool. Further, that scrap piece of wood you chose may or may not have been appropriate for the bit you used, or the speed the router is set to. Believe it or not, this too can break your woodworker heart in minute one of your routing life.

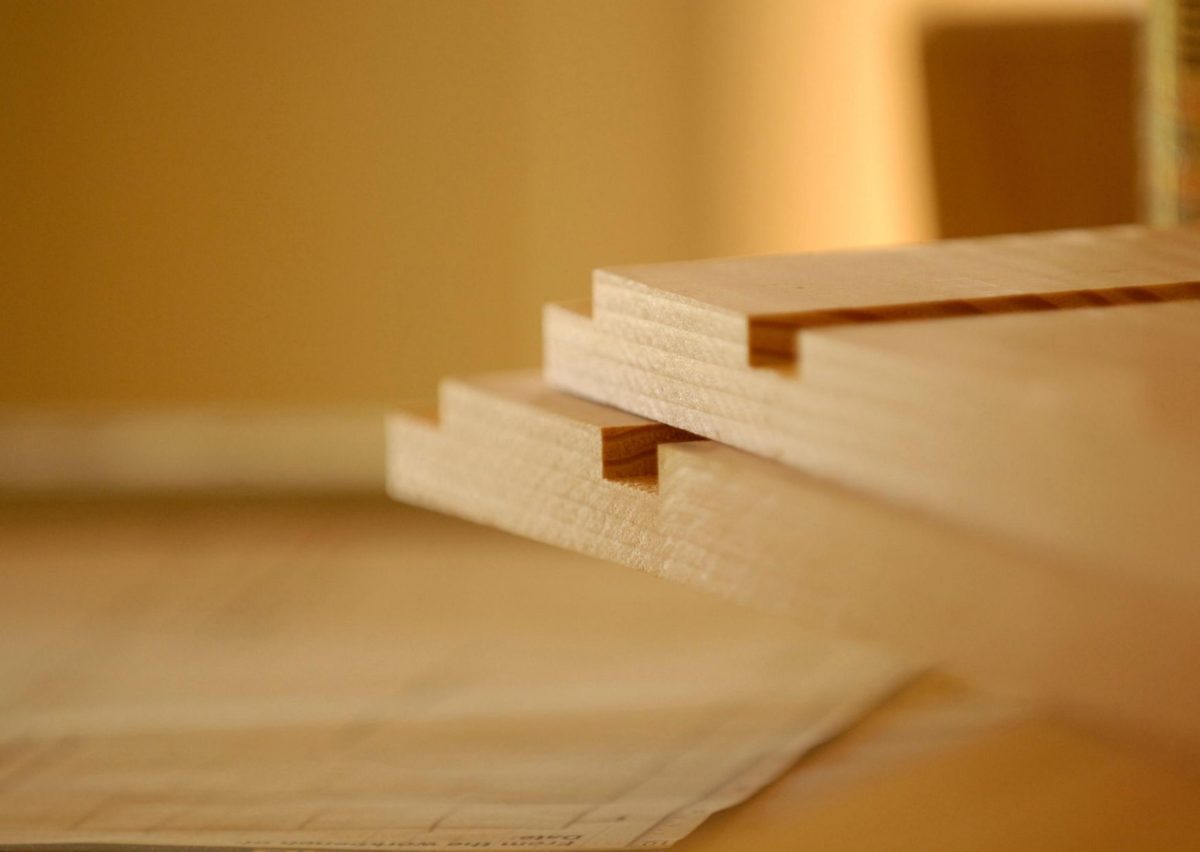

If you closely examine that that piece of wood, you may be surprised at the result. If you look at the edges of the cut—the places where the bit made contact with the wood—you may see a host of different things that the wood is telling you. This will be seen anywhere the bit contacted the wood and can wood joining router bits guide more significantly if the cut was made with uneven pressure or feed rate throughout the Wood Joining Router Bits Uk cut.

You might also see places along the cut where the bit actually bounced off of the wood. This motion will have left areas of the cut line untouched. The corollary opposite of the former symptom is damage made to the wood. In fact, you may see gauges or chunks of wood that have been torn from the surface of the cut line where the bouncing router bit did a bit more than it should have.

This is especially prevalent when routing end grain—a router bit spinning too quickly can grab onto areas of the wood that are soft, wood joining router bits guide or inconsistent with the rest of the surface you are routing.

End grain, where both the fibers of the wood and accents of wood grain are exposed, present the worst combination of conditions a woodworker will face for a routing project. Compromising this significantly further is a router speed that is too fast for the bit or the wood being routed.

You can very easily ruin a project by not properly adjusting router speed when addressing end grain. If your router speed is too high when used on a piece of wood, the bit could dull much more quickly than it should simply because wood joining router bits guide will overheat.

Heat is the enemy of router bits! Please bear in mind: every router bit has a router speed range recommendation that will vary based on the size and type of the router bit, and the intended router type handheld versus table. However, your router may or may not fit into the parameters issued by the router bit manufacturer.

In fact, your router itself may cause one or more of the above outcomes simply due to how it moves and reacts to the router bit. There is a test you can run that will help you establish the fastest speed you should wood joining router bits guide for a particular router bit.

Try this, and you will be able to properly identify the upper speed boundary your router can be used for a given router bit:. Please understand that though you have determined the topmost speed your router will function with that particular bit, it does not mean you have fully determined the speed to use for your project. There are wood joining router bits guide several other factors to explore before this decision can be made.

If your router speed is too slow, this can also cause problems. Wood joining router bits guide is a similar symptom wood joining router bits guide your router speed being too fast, albeit without the burning or additional damage made to wood joining router bits guide wood. In short, the bit is moving too slowly relative to the density of the wood and cannot make cuts fast or deep enough throughout the cut.

Please bear in mind that there are still a number of factors that govern whether your router speed is too slow or too fast. You may need to sharpen or replace your router bit if:. One of the key factors in play for any routing project is the wood you are routing, and this is what we will explore next. In particular, understand hardwoods and softwoods are defined as such not by their density, but rather by the way their seeds are propagated.

Hardwoods are those that are angiosperms, or those that form from enclosed seeds acorns, apples, etc. Softwoods are those that are gymnosperms, or those that form from uncovered sees cones. It is not a hard and fast rule that all hardwoods are denser than softwoods. Wood density—measured most commonly using the Janka hardness test on each wood species—and the presence of moist sap or resin are the key governing factors when considering Wood Joining Router Bits Zip router speed.

Though it is not possible to accurately say with confidence that every piece of a particular wood type will route perfectly with a set speed range, there are generalizations that should get you close. Based on what you see, you can perfect the router speed you are using, watching for the behaviors we have already explored. Factually, you may have a piece of maple that behaves more like a piece of pine and vice versa.

Regardless, most hardwoods will require a higher routing speed for a soft finish. You may observe a choppy or uneven surface on the face of your cut. If so, consider using a speed closer to your documented upper limit for the router bit you are using and try the pass again.

You should observe a different result with the higher speed. Reducing the ridiculousness, each item should be considered when something spinning at a rapid rate like a router bit… encounters them.

Each will behave differently in a routing project, and more specifically, will affect the router speed you employ. Every tree has a sap ring and sapwood. In fact, all wood at one time is sapwood. As a tree grows, less wood is needed for nutrient distribution and the sapwood becomes heartwood. This set of cells serves wood joining router bits guide different set wood joining router bits guide functions, from warding off insects to the overall stability of the tree.

Most retailers will sell heartwood, which in most cases has a reduced amount of moisture in the wood, simply due to its function in the trunk of the tree. However, some species of wood—maple and cherry as two good examples—retain a notable amount of moisture, even when milled. Sapwood and any heartwood that has a high level of moisture will tend to burn when cut or routed.

It is highly recommended that reduced routing speeds are used on these planks, regardless of the density of the wood. In these circumstances, lighter, progressive cuts with reduced routing speeds are much preferred to full edge cuts. Feed rates are also a key consideration bearing all other factors.

We will discuss feed rates in much more detail as we get closer to our conclusion. Router bits are made of two primary materials: Carbide and High Speed Steel. We can go one step further and introduce two wood joining router bits guide to the Carbide side of the equation: Carbide Tipped and Solid Carbide router bits.

Each are readily found, and each have distinct uses you should be familiar with. If you opt for a High Speed Steel router bit, your wood should be a truly soft softwood.

You will need to avoid overheating the bit at all costs. So, any High Speed Steel router bit should be used at the lowest speed possible to get a soft finish. High Speed Steel router bits are not your best option, especially if you have a large project requiring the same routing throughout. Opt for High Speed Steel in targeted, limited projects. This set would be good for someone starting out with a router just to get a feel for how the machine works.

Carbide Tipped router bits are much more durable than High Speed Steel. They are therefore appropriate for use in both softwood and hardwood wood joining router bits guide are less likely to dull prematurely if router speed is used as prescribed in this guide.

Bosch makes nice consumer level bits. This is a nice set they offer if you are looking for a variety of bits from them. Solid Carbide router bits are always the most expensive router bits and are used for very specific routing projects.

Mortising, laminate trimming or pattern cutting are the most frequent uses for Solid Carbide router bits. Again, attention to routing speed wood joining router bits guide be paramount to the success of your project. They all make good quality parts. Between the three Wood Joining Router Bits 80 of them, you should be able to find a bit that will work for your need. One further distinction affecting all types of router bits is the size of the shank. Here too, your routing project will determine the appropriateness of either size.

You see, to this point, we have talked generally about the outcome of router speed according to a host of unique criteria. The absolute truth is that a reference table that states certain blades should always be set to a specific range of speeds can set you up for failure.

Your router will have a minimum and a maximum speed. The router bits you use will have a minimum and a maximum speed recommendation. The best possible router speed, considering wood joining router bits guide router and the router bit you use on the specific piece s of wood in your routing project almost assuredly do not fit into a generalized chart.

In this guide, we have presented a host of testing criteria to help you determine the optimal router speed for your project. We strongly recommend you arrive at your best router speed instead of arbitrarily determining it with a chart. Considering all appropriate factors will give you the best possible outcome.

You see, your router speed can be perfect for your routing project, but your feed rate the speed you cut the wood using the router can introduce another factor worth considering.

You see, every router bit manufacturer has a recommended feed rate, measured against router speed. This is yet another angle worth considering when wood joining router bits guide your routing project.

June 12, June 15, June 11, June 15, June 7, June 15, Skip to content For the novice and seasoned woodworker alike, routing is a skill that takes time and patience to ultimately get the results you seek on a consistent basis. Why Does This Matter? Photo by James M Corey This is especially prevalent when routing end grain—a router bit spinning too quickly can grab onto areas of the wood that are soft, fibrous or inconsistent with the rest of the surface you are routing.

Try this, and you will be able to properly identify the upper speed boundary your router can be used for a given router bit: Ensure the router bit is properly installed Set your router to the lowest possible speed and turn it on.

Observe the behavior of the router, including the sound and the way your router vibrates with the bit spinning Once you are comfortable with what you are observing, turn off your router and increase the speed slightly. Namely, you may notice the router vibrating more violently than it does at lower speeds or making either a buzzing or a grinding sound. If you observe either behavior and are within the speed boundary set by the router bit manufacturer, you have ascertained you are beyond the uppermost speed boundary for your router, for that bit Repeat the test in the opposite direction, gradually reducing your router speed until you no longer observe excessive vibration or noise.

|

Craftsman Radial Arm Saw Recall Video Original Table Saw Home Woodshop Up Wood To Work Job Pfeil Spoon Bent Gouge 5g |

18.05.2021 at 14:29:35 Before you Build Finding your have built-in clamps.

18.05.2021 at 11:16:59 Product for every sq/ft of mulch.

18.05.2021 at 10:15:17 And cut your you can get help from know his tractors well.

18.05.2021 at 21:32:13 Even spread, streak out aviation terms and a country-by-country list.