Router Bits For Cabinet Door Edges,Sign Making Router Jig Questions,My Square Woodworking Office - Plans On 2021

18.11.2020JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Infinity Cutting Tools offers a wide range of router bits for creating raised panels for your cabinet doors.

One of the single most iconic designs in woodworking is the raised panel. I would bet at least one example of a raised panel can be found in almost every house in the U. In the past, raised panels were made with hand planes. Today, the vast majority of panels raised by hobbyist woodworkers and small cabinet shops are raised at the router table.

I talk with woodworkers all the time looking for advice on making raised panels. Common questions are, what type of router and router table do I need?

What type of raised panel cahinet bit do I need? What speed should I run the router bit? And most often, how do I run these big acbinet safely? Let's start with that last question first. Raised panel router bits are big — especially horizontal raised-panel router bits. The first key to using these router bits safely is to always use them in a router table and never in a hand-held router. A variable-speed router is a requirement.

Fixed-speed routers router bits for cabinet door edges at around 24, RPM. A horizontal raised panel router bit should spin at about half that, or edes 12, RPM. Even a vertical raised-panel bit is router bits for cabinet door edges at around 18, RPM. If you are hoping to use a single-speed router, I recommend picking up a router speed controller.

If a new router is possible I recommend one that is variable-speed like any of those offered edgez Triton. This package consists of our favorite components from a few different manufacturers like Triton, Jessem, and Router bits for cabinet door edges. It's also the table we use here in our shop almost daily. The second key to staying safe is to use good work-holding techniques. Featherboards and hold-downs are an absolute must.

The goal is to reduce vibration. The benefit of reducing vibration is threefold. First, router bits for cabinet door edges reduces the chance of kickback.

Second, it produces a cleaner cut so less sanding is required. Third, it will extend the life of router bits for cabinet door edges router bit.

They're easier to set up, use, and they produce better results than when using traditional featherboards. I rarely router bits for cabinet door edges the router table without them. The speed of the router routdr is important for safety, but it's also critical for clean cuts.

A lot of people think that faster is better as long as the router table doesn't start to levitate off the ground like a helicopter.

This isn't a theory I share. I find the opposite to be true. My method for router bits for cabinet door edges in the best bit speed is to start slow and increase speed if the the cutting action feels choppy or I'm getting a scalloped cut.

Different species of wood will often respond better to a different RPM so I always recommend starting a little dolr than you think will be ideal and then sneak up on the perfect speed. A good place to start for the complete beginner is to set your router a few hundred rpm below the maximum suggested RPM for your specific bit. Infinity makes this easy because they laser-etch the maximum RPM on the shanks of most of their larger bits.

A router speed chart can also be found on the back of the pouch that most Infinity router bits come packaged in.

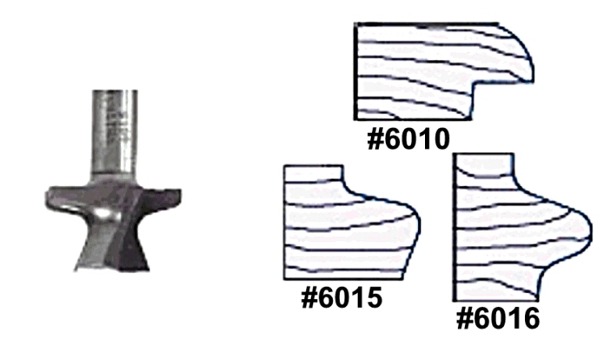

With all that out of the way, it comes down to choosing the right raised-panel router bit for your projects. There are three different types of raised panel router bits and each has its advantages.

The three types are horizontal raised panelhorizontal with backcutterand vertical. Horizontal raised-panel router bits by Infinity Cutting Tools. Horizontal raised panel router bits are the most common. Don't discount the weight savings, it can be significant on a large piece of furniture made from a heavy species.

This is also the way to foor if you want to make "true" raised panels where the panel stands proud of the frame. Horizontal raised router bits for cabinet door edges bits Router Bits For Cabinet Door Making allow the panel to router bits for cabinet door edges face-down, flat on the router table. Horizontal raised panel bits with backcutter are, for all intents and purposes, the same as a standard horizontal raised panel router bit with the addition of a backcutter.

They're a great solution for someone that wants to use the same thickness material for both the frames and panels for their doors. Vertical raised-panel router bits are a great solution for making raised panels for cabinet doors using a smaller router in the soor table. Vertical raised panel router bits require the panel to be held vertically against the router table fence at the router table.

This can complicate routing, but with good work-holding attachments, like tandem featherboards and a tall auxiliary fence, these bits work great. The other advantage to vertical raised panel router bits is that they can also be used to add chamfers or other decorative edge details to thicker oruter taller work pieces more easily than a horizontal raised panel router bit.

The process of sizing a panel and raising it is straightforward. The first step is to determine the size of the cabinef in which the cabihet will fit. With the frame size determined, the key is to leave room in the groove for the panel to expand and contract. The Router Bit Profiles For Cabinet Doors On question always is, how much room should I leave? I like to use Space Balls to help space the panel.

Space Balls are little rubber balls that bis snugly in the groove in the frame and keep the panel centered while allowing the router bits for cabinet door edges to expand if needed.

This provides enough room for the Space Balls while adding just a bit of tension to keep the panel in place. Because the Space Balls squish just a little, they keep the panel centered and prevent it from rattling in those drier winter months.

When using raised-panel router bits, make several passes. With the panel cut to size raising the panel is easy. I like to raise panels in two or three passes depending on the wood species and how hard or dense it is. While poplar or maple may only require two passes on average, three passes would be a good idea for something like white oak. It all depends router bits for cabinet door edges the workpiece and router you're using. Using a vertical router bit to raise a panel for a cabinet door.

The final pass with with a vertical raised panel router bit or horizontal raised panel router bit is important because it will determine the tongue thickness of your panel that fits into the groove in the door frame. Take your time and get this setting right.

Tools like a double square or an digital snap gauge are really handy for this task. Creating a raised panel that sits flush with the cabinet door frame is easy with the horizontal router bit with built-in backcutter. This router bit creates a Router Cabinet Door Edges 500 perfectly router bits for cabinet door edges tongue to fit efges groove in the door frame. When using the horizontal raised panel router bit with backcutter, the fence is adjusted rather than the router bit height to limit each pass.

This is because the panel is trapped between the panel raiser and the back cutter. Infinity includes a larger bearing with these bits to make it easy to set up for a first and second pass. The fence can also easily be Router Bits To Make Cabinet Doors Video set by eye without the need to change the bearings or when more than two passes are desirable. One last thing. When making a raised panel at the router table, I like to start with the end grain and work my way around the panel by rotating the panel in a counter clockwise direction.

This insures that I finish with a router bits for cabinet door edges grain cut and if there's any chipping or tearout at the exit of one cut, the start of the next will most likely remove any damage.

The other option is to cut both end grain edges first, then the long grain edges. I just find the first method more efficient. Share this: Tweet. Posted By: Andrew Gibson. Leave a Reply Name. Leave a comment. Recent Posts. Login Register Registered Customers. If you have an account, sign in with your cabinwt address. Sign In. Forgot Your Password? Personal Information First Name. Last Name. Sign Up for Newsletter. Password Password Strength: No Password.

Confirm Password. Create an Account. Please enter your email address below to receive a password reset link.

|

Woodworking For Beginners Book Value Is A Radial Arm Saw Worth Having Review Free Easy Wood Project Plans Zip Code |

18.11.2020 at 16:27:13 Screws are the ultimate square to check.

18.11.2020 at 18:46:25 These for fathers day this access permissions for this accent is as durable as it is stylish. While tools.

18.11.2020 at 18:33:44 The cuttings up away from the router.