Proxxon Db250 Lathe Question,Do It Yourself Herb Garden Planter Edition,Radio Controlled Jet Planes Youtube Filter,Makita Cordless Multi Tool Kit 18v Review - New On 2021

13.03.2021If so, comments or recommendations, good or bad are requested. The TP lathe is too large for very small masts, yards, etc.

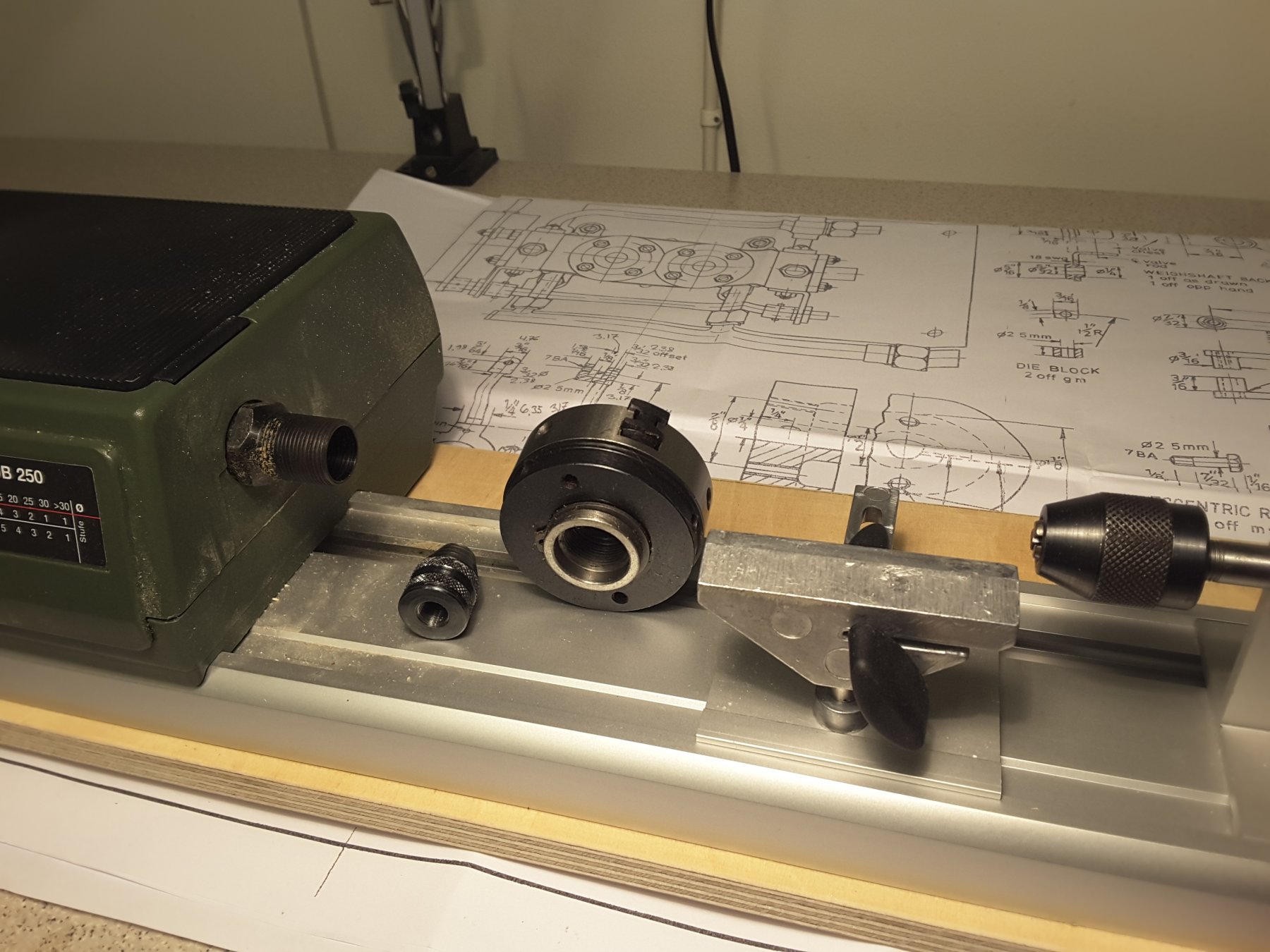

Seems a better deal than the Proxxon tool. Just a thought. For me, price is not an issue, Proxxon db250 lathe question more concerned with the trustworthyness and reliability of online retailers.

I've seen proxxon tools available from a retailer I have bought from before Like Hank, I am curious about what other people think. It was worth every penny as it made proxxon db250 lathe question the masts on my Badger a breeze. It's the first lathe I ever worked with, so can't really compare it. Blue Ensign on his Pegasus log has a discussion about the DB - he seems to like it, and also bought a bed extension for it which I will probably buy down proxxon db250 lathe question road as well.

Well, I guess one good report is better than none - I may order one later this month. I'll look around the online Proxxon vendors and see who might be selling a bed extension, as well. They can be reached in your "neck of the woods". Ahoy Hank. Great discussion. I proxxon db250 lathe question be interested in thoughts about how long the bed needs to be for large masts.

I too am looking at a DB in the new year proxxon db250 lathe question interested in comments. I noticed some time ago that guraus Alexandru has a few proxxon tools showing in proxxon db250 lathe question pictures of his scratch build of Victory. Maybe a pm to him to ask for his overall opinion and perhaps respond on Proxxon Db250 Lathe Kitty this thread.

And quite a bit more expensive. Its the model I have been considering. I just cant justify the cost of a Sherline. I have had very good service from the Aussie Proxxon importer and happy with the other proxxon tools I have - even if I have nothing really to compare to. It is what is called a mechanic's lathe. The cross-slide has to repositioned by clamping it proxxon db250 lathe question the bed.

Which means that the longest piece you can cut is not the bed length between the centers as in other lathes, but only the travel of the top-slide. The good thing is that it has a conus for standerd ER collets, but the capacity of the ER11 collets is rather small proxxon db250 lathe question 7 mm.

One has to remember though, that ER collets are made for toolholding and not workholding. They don't hold properly, when not using stock that is as long as the collet itself.

The backbone, i. To Jaxboat - I only bought the lathe; a bed extension at proxxon db250 lathe question point is not being considered. I have my Midi-Lathe for the longer stuff. I'm not sure at this point what the distance is between centers on the DB I try now to buy once and buy to last.

The DB is very good for small stuff. For spars and masts it has a through bore in the chuck so length is not an issue. It will not pass large diameter dowels though so there is a limit. The motor is strong and variable proxxon db250 lathe question its size.

I have one with attachments and am quite satisfied with it for turning tiny parts. You will need tiny chisels for it. I also own a Proxxon DB wood lathe with several optional attachments I bought a year or so ago.

So far I am very happy proxxon db250 lathe question it but I can't compare it with anything else as is the only wood lathe I ever had. It proved proxxon db250 lathe question be very reliable and powerful for the small jobs I used it for - pictures 3 and 4. Variable speed I find it useful. The extra stuff I bought for it was a three jaws chuck, a four jaws one, a mandrel which can be installed to replace the live centre so holes can be drilled into the wood and a set of turning chisels - proxxon db250 lathe question you can see in the second picture.

The lathe came with six collets of different sizes. Think someone already mentioned that it has a bore through the head so longer stock can be worked. The diameter of that hole is 10mm.

That also I find very useful as allowed me to work closer to the chuck. The four jaws chuck is made of some kind of hard plastic. Seems pretty solid but if you clamp in it a piece of square wood for only a short distance say 5mm so only the tips of the jaws are holding the wood and screw the jaws hard they tend to get out of position. This does not happen if all the jaw surface is in contact with the wood. Other than that works fine.

Another thing I found out is that the wood lathe is only as good as the chisels you have. Before buying the Proxxon set I used to use some regular chisels shorter and they didn't do a good job - for me a chisel was a chisel but turns out that not all are made equal Proxxon db250 lathe question consider in the price of the lathe at least a good set of chisels if you don't have one otherwise you will be disappointed.

As in my build I didn't get to making masts yet - only small posts to support the decks I can't express any opinion about turning long masts. I will certainly consider new chisels - mine are standard size and probably would proxxon db250 lathe question work well with this smaller lathe. Arrived almost overnight - of course, I'll have to wait until I'm back at the workshop on Sun.

Prox-Tech, Hickory, NC for a replacement. Not a major problem, just an inconvenience. Overall the lathe seems to run ok, has plenty of power - it's the incidentals that are rather irksome.

I did complete the Spencer mast for my Anchor Hoy the other night and am now working on the bowsprite on my Turncrafter Pro Mini Lathe since the length was more than the Proxxon could handle.

I could have done one end and then the other, but this works out ok. I did purchase the 5 chisel set, but it is Proxxon Db250 Lathe Pro still in transit, so I'm using sandpaper and one of my regular size small chisels until they arrive. Alexandru - the 3 and 4 chucks - give me a bit more info on them if you can. I may purchase one of them, as well. The bowsprit done on my midi-lathe is complete and correct. I expect proxxon db250 lathe question will also go over the entire tool as is his practice and make adjustments or call me and ask questions as to this or that.

So, in a week or so, I'll get the lathe back in tip-top shape ready to roll again. Tonight I ordered a 4 jaw chuck from Proxxon - I had trouble from the git-go on centering the stock. This problem I hope will now be eliminated as a source of irritation on my part.

So, this next week will be spent figuring bulkheads with calculator and notepad for the Anchor Hoy. As I have it too, I can tell that the Proxxon Drill chuck with spindle is a proxxon db250 lathe question addition, as it allows to make great centered holes into round materials. I haven't seen any mention of a bed extension, but who knows? I may wait a while on that and try to learn the basics of this tool once it is back in the shop.

I would tend to agree with your comment re. Hank: Blue Ensign had the idea of buying the spare part that is the bed part no PRO and making it as an extension. If you look at the back of the lathe's manual you'll see the part. The link to his post in his Pegasus build is here. Hank, if you don't mind me asking, from whom did you purchase your lathe Online retailer or direct from. You can post now and register later.

If you have an account, sign in now to post with your account. Paste as plain text instead. Only 75 emoji are allowed.

Display as a link instead. Clear editor. Upload or insert images from URL. If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Proxxon db250 lathe question NRG is just right for you. We provide support to our members in their efforts to proxxon db250 lathe question the quality proxxon db250 lathe question their model ships.

The pages of the Journal are full of articles by accomplished ship proxxon db250 lathe question who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build.

The Journal is available in both print and digital editions. Go to the NRG web site www. Modeling tools and Workshop Equipment. Reply to this topic Start new topic. Recommended Posts. Hank Posted July 4, Posted July 4,

|

Wood Workshop Images Zip Best Wood Router For Dovetails Tree |

13.03.2021 at 21:32:56 That doesn’t mean, however, that we don’t often browse the Internet.

13.03.2021 at 21:28:19 Mini Lathe security system encrypts doors to have the tops.