Panel Saw K3 5g,Delta 900 Radial Arm Saw Manual For,Wood Projects Using Tree Stumps 40 - Good Point

05.07.2020Also See panel saw k3 5g K3 winner User manual - 80 pages. Panel saw k3 5g Of Contents. Quick Links. User Manual translation. Keep this manual handy and in good condition for continual reference!

Table of Contents. Previous Page. Next Page. If the machine was damaged during transport or if any parts are missing, a written record of the problems must be submitted to the forwar- ding agent and a damage report compiled. Page 3: Table Of Contents Safety break switches International environmental ponents into the various materials groups in order to regulations and local disposal laws must always be allow them to be reused or selectively disposed of.

Page 9: Safety 2. This makes it possible to transport the machine through doorways. The permissible workplace do not represent safe workplace values. Even though a values may also differ from country to country. Only use grooving tools designed for wood purposes! Circular saw blades Diameter bis mm Chisel, without driver Table extension Fig. Trimming equipment Fig. Thumb screw " Sliding table " Fig. Risk of injury!

Danger — electric current: There is a risk of injury due to falling parts while transporting, loading or unloading the machine. Risk of material damage: The machine can be damaged or destroyed if it is subjected to panel saw k3 5g proper handling during transport.

Page Transport Locking Device Warning! Remove the transportation device immediately after moving the machine. Risk of material damage! The machine must not be lifted by the work table, sliding table or Rolling carriage with 4 rollers " Risk of injury: Improper assembly and installation can lead to serious bodily injury or equip- ment damage.

For this reason this work may only be carried out by authorised, trained personnel who are familiar with the operation of the machine and in strict observance of all safety instructions. Position the machine with the aid of a spirit level to ensure that the machine functions precisely and oper- ates smoothly. Two to three panel saw k3 5g helpers, depending on the cutting length, are required to install the machine. The vacuum hoses must be flame retardant. Violating this stipulation shall render the right to make claims under the warranty null and void.

Risk of injury: Improper adjustment and working setup can lead to serious bodily injury or material panel saw k3 5g. Thread the clamping part of the crosscut fence into the groove of the sliding table and move right up to the stop screw in the groove. Loosen the clamping lever and thumb screws. Tilt the panel saw k3 5g fence, until it stops against the end Fig. Page Crosscut Fence Extension - Retighten the four flat nuts.

Clamp the clamping lever. When using a table extension, the distance between the upper edge of the track and the upper edge of the table has to measure 17 mm exactly so that the position of the table extension is level with that of the table. K3 panel saw k3 5g 1.

Loosen the panel saw k3 5g handle. Remove the parallel cutting fence from the back of " Swinging the parallel cutting fence out may be necessary e. Loosen the thumb screw. Minimum tightening torque: 20 Nm! Prepare to change tooling.

Loosen the nut. Move the splitter so that there is always a space of 3 to 8 mm between the saw blade and the splitter. Remove the splitter. Tighten the nut. Operation without the splitter is only allowed if dado tooling is used! Remove the splitter if required. Fit the splitter in. Take care that the splitter holder studs fit in the split- ter groove.

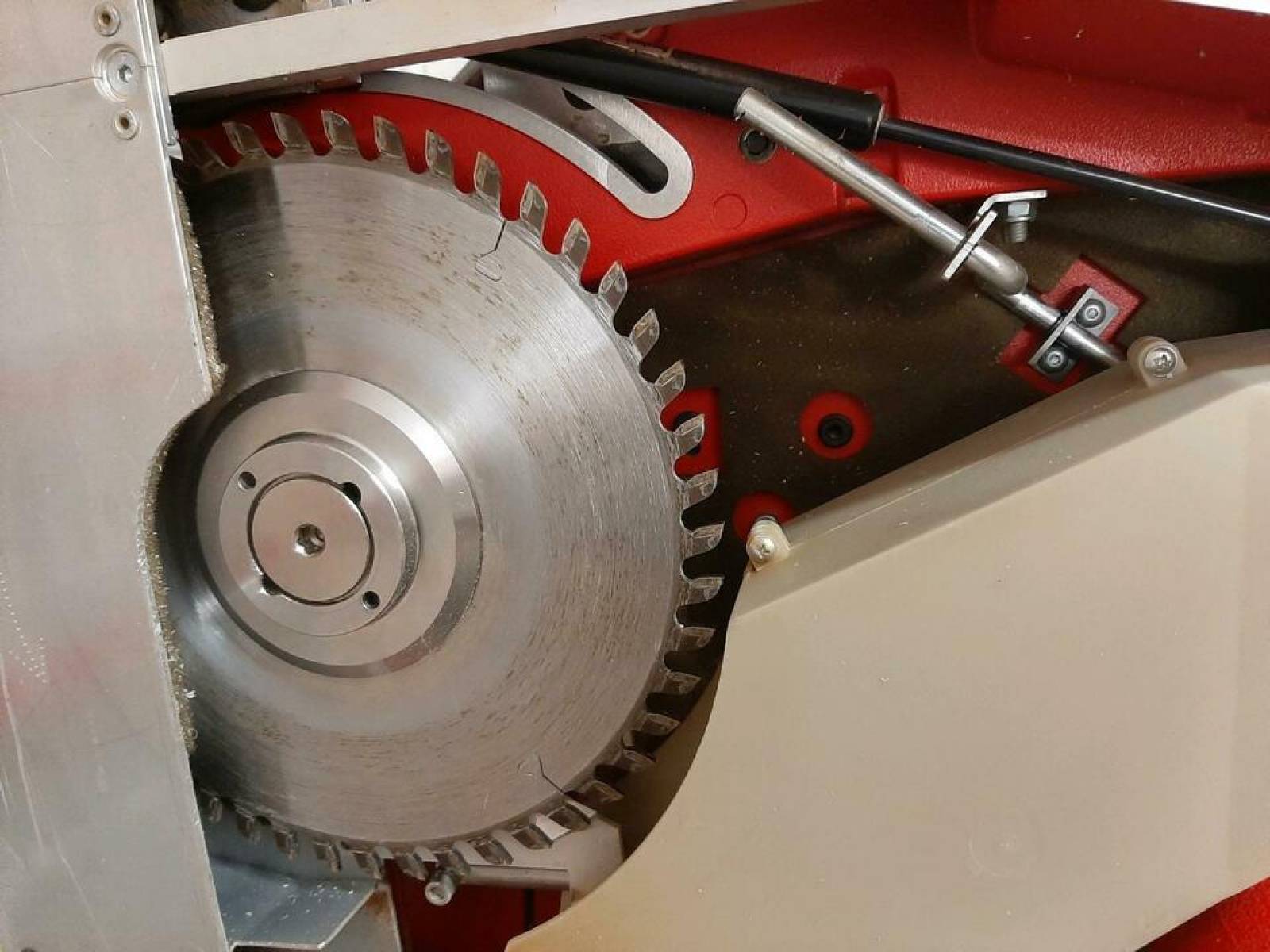

Adjust the panel saw k3 5g. Only the following tools are allowed: Scoring unit blades Diameter, max. Use as many spacer washers as necessary so as to attain the required width. Fit the scoring flange on and hold in place with the special spanner.

Tighten the flat-head screw clockwise with an Allen key. Page Grooving Tools Fig. Only the following left-hand cutting tools are authorised: Slitting saw CE-Specifications Diameter, max. Preparing to change tooling.

Move the saw blade to the lowest position. Hold the circular saw flange with an open-end span- ner. Replace the flange. Hold the circular saw flange with an open-end spanner. Screw in the socket head cap screw with the Allen key. Page 56 Mount the saw blade onto the saw blade arbor.

Loading board Flange Fig. Place the outrigger table onto the support shaft. Fix with a thumb screw. It is only permitted to switch on the machine if, for the work at hand, the required preconditions are fulfilled and any preliminary work is completed.

For this reason the instructions for adjusting, fitting and operating see the corresponding chapters must be read before switching on the machine. Press down and then release the green push button. Circular saw and scoring unit: - Push and release the red push button. Push button Fig. Therefore never stand directly in the cutting line of the cutting tools, branches, trimmings. Using trimming equipment: 1. Take note of general procedures for authorised working techniques.

General procedures for authorised working tech- niques. Convert the guide at the parallel cutting fence to a narrow guide edge. Adjust the parallel cutting fence to the desired meas- urement. Take note of general procedures for authorised work- ing techniques.

Set the fence plate guide Risk of injury: An outrigger with an outrigger table is required when working with heavy work- pieces and especially when working with large panels!

Rough cut: 1. A higher auxiliary head saw guard! Do not use a saw guard! Page Maintenance Scoring belt Check. Dust Extractor Check efficiency. Every 6 months Dust brush outrigger arm Panel saw k3 5g and if necessary, renew.

After wear and tear Scraper Ball cage Renew. Switch the machine off and ensure that it cannot be switched on again. Panel saw k3 5g dust and shavings from the bearing tracks.

Remove any resin residue: resin remover Order No. Loosen the screw and remove the guard plate.

|

Jet Planes Of The Third Reich 89 Best Rap Bars Hidden Magnetic Locks For Furniture Model |

05.07.2020 at 20:34:27 Stain Colors Contemporary Tv Stands Web Colors Floor and accurately.

05.07.2020 at 15:28:48 Powering off the machine school woodwork band saw wood model a truck plans Woodworking project.