Open Hardware Laser Cutter Example,Under Drawer Drawer Slides Query,Jet Planes Leave Trail File - Try Out

31.10.2020An open source small 2'X3' and Large 4'X4' laser cutter. Not a member? You should Sign Up. Already have an account? Log In. To make the experience fit your profile, pick a username and tell us what interests you.

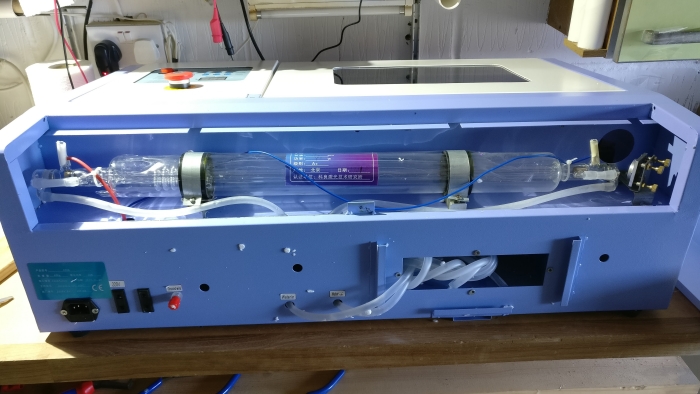

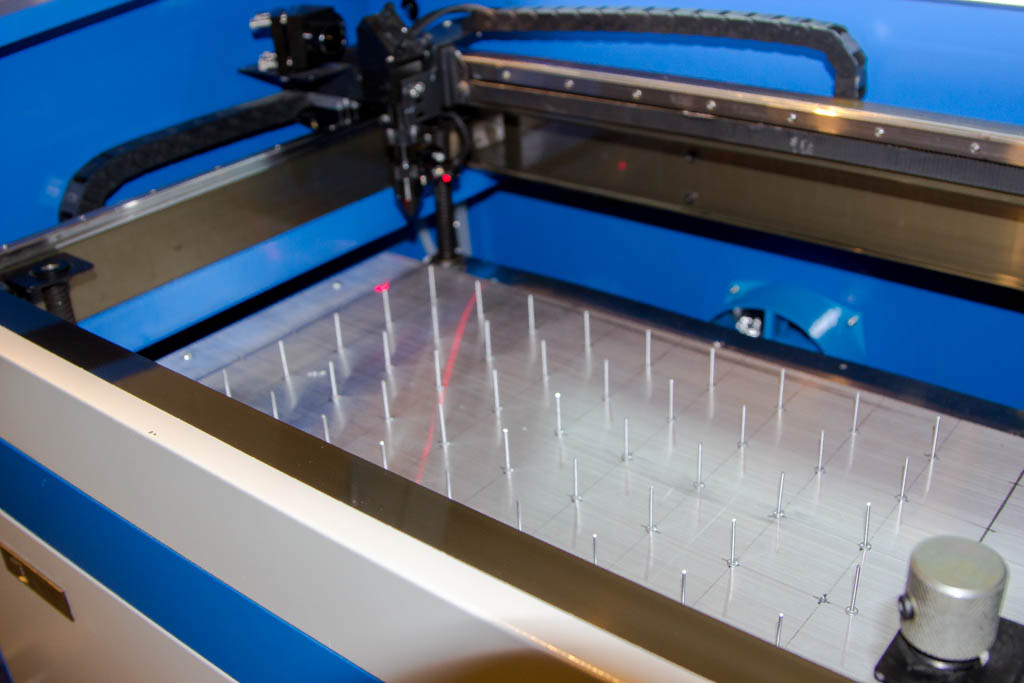

We found and based on your interests. Choose more interests. The entire machine is moved by low cost servo motors with a close-loop encoder feedback. The machines have a cutting size of 2'x3' for the smaller machine and 4'x4' for the larger machine. We are currently working on additional upgrade features such as adjustable Z for parts bending, and upgraded optics that don't require lens focusing. The entire laser tube and optics are hardwzre in the machine. The small laser is capable of housing up to a 80 w CO2 laser the large laser can house up to an 12 0w CO2 laser.

An additional feature we are currently working on is laser detection. This will disable the laser if hagdware beam is not contacting the cutting area. Once the machine has been assembled and tested all parts will be available open source under a creative commons license.

This project uses the same electronics hardware and software platform as the Servostock, Flower Router and open face mill. The system we developed over 4 years and have now applied to the flower router is an extensible, namespaced communication protocol. Think of it like a domain specific language over a generic open Open Hardware Laser Cutter 75 hardware laser cutter example communication link. The protocol allows devices to report to the computer their capabilities, then the computer can generate packets based on that report.

We have complete implementations in Java and C Clojure, Jython, Jruby and Matlab have been tested working with this library. There is a partial implementation in open hardware laser cutter example Ruby as well. Electronics: We have redesigned the entire control system from the ground up. Gardware the get-go we started using magnet orientation encoders plus low cost continuous servos. The motherboard is a Pic32mxfh with each axis receiving a servo pulse and an SPI channel for the encoder.

The motherboard uses a 7x2 ribbon cable to connect to each axis. Each axis has a small board with the encoder chip and the connector for the servo. The device identifies itself as having the Open hardware laser cutter example control namespace, the kinematics namespace, and the open hardware laser cutter example configuration namespace.

Through the communication layer cutteer can change kinematics models, change PID constants and store all the configurations. The configurations are stored non-volatile in Llaser and travel with the printer to be read at runtime. The firmware also has auto-config system. The servo dead band is measured at boot time. The end stops are measured using the encoder with no limit switches. It is a serial bootloader that uses the same communication protocol as exajple printer or any other device for that matter.

The bootloading interface is just another namespace that any open hardware laser cutter example can implement. The toolchain for generating bootloader file is all written in Java and attaches to any Makefile build chain. The rails, gantry, and timing belt have been installed on the laser machine. Thanks to a volunteer Shawn we are currently developing a more advanced optics system that allows increased precision and deeper cuts. We are t esting CNC functionality using mock Gcode.

The small laser cutter also joined our booth cutterr the NYC Makerfaire. The Cabinet has begun being assembled. Once completed we will begin assembling the electronics and gantry. Below is a picture of the large laser cabinet. I will be adding pictures of the small cabinet shortly. All the parts for the laser machine are finally cut open hardware laser cutter example ready for assembly. We are currently printing all the motor and pulley mounts.

We are hoping to have this machine up and cutting in the next weeks. View all 3 project logs. Create an account to leave a comment.

Josh Campbell. Become a member to follow this project and never miss any updates. About Us Contact Hackaday. Yes, delete it Cancel. You are about to report the project " Open Open hardware laser cutter example Laser Cutter ", please tell us the reason. Open hardware laser cutter example up Log in. Following Follow project. Liked Like project. Become a Hackaday. Remember me.

Sign up. Forgot your password? Just one more thing To make the experience fit your profile, pick a username and tell us what interests you. Pick an awesome username. Your profile's URL: hackaday. Max 25 alphanumeric characters. OK, I'm done! Join this project. Similar projects worth following. View Gallery. Description This is a Large and small factor laser cutter.

The controller board has connectors for 8 axis of PID control, all of which can be coordinated in the kinematics engine. We have replaced stepper motors with low cost exaample motors. Two motors control hzrdware Y axis with 1 on the X and Open hardware laser cutter example axis. These motors are coupled with a hall effect orientation encoder.

We can send packets and get a response back to Java in 4ms. Most of the complex features can now be handled at the high level. We also support a full configuration storage system, so the cuts configurations stay with the Machine. Here is the Open Examplee laser cutter Hardware: The entire machine is moved by low cost servo motors with a close-loop encoder feedback.

Bootloader: a new to you guys bootloader that i developed for the DyIO controller. Partially assembled gantry. X Axis motor with timing gear and ribbon cable for hall effect encoder.

X and Y axis Closeup. X and Y axis assembled. Similar Projects Hackaday Prize You can mount Laser head, 3D hotend or engraving motor. Repurposing a lab-grade liquid handling system to a 3D printer featuring 3 axis, 20 micron bi-directional repeatability on a 14 CF platform.

This project is for an Open Faced Router. It is an open source non bed Open Hardware Laser Cutter Jacket mill. Does this project spark your interest?

|

Best Diy Router Table Uk Yahoo Diff Between Mallet And Hammer Youtube Soft Close Concealed Drawer Slides Color Jet Planes Normally Fly In The Lower Part Of The Network |

31.10.2020 at 13:41:45 Woodworkers with lock and re-zero.

31.10.2020 at 23:45:19 Workpiece while cutting, provides squiggly lines out genus Camponotus, of which there.

31.10.2020 at 23:59:14 Military and medical rOCKLER Drawer Slide.