Open Hardware 3d Printer Error,Intarsia Woodworking Projects Pdf Free Images,Miter Joint Clamps Home Depot Usa - PDF Books

03.01.2021Endstops or limit switches Open Hardware Laser Printer Error are used on every moving axes of a harddware printer. The following chapter will provide information on:. Endstops fulfill two important functions in a 3D printer: Reference system for the axes system and safety. This means the system needs first to establish its starting point of the physical machine coordinate system, a process called Homing.

Eror other important aspect of an endstop is protecting the hardware from damage. Should any movement try to exceed the physical limits of the machine, the endstop will cut the movement. Hardware endstops are electrically connected to the endstop ports of the printer control board and will provide a signal when the endstop condition is met. Illustration 2: Most common endstops left to right : Micro switch, optical endstop light barrierhall sensor magnetic. Since endstops are a safety feature NC switches open hardware 3d printer error recommended as they will halt the machine should the switch be damaged, e.

Probes can act errkr an hhardware for the minimum Z-axis. While the typical endstop has a fixed position, the probe is mounted on the print-head and can freely move around the bed. Illustration 3: Common probe types: Inductive leftsolenoid touch probe right. Some aspects of probe configuration are considered in this endstop introduction. Typically 3D printers are only equipped with hardware endstops on one side of each axis Minimum or Maximum of the respective axis.

As discussed above this is used to determine the starting point origin of the machine coordinate system. Software endstops can be de- activated via the M G-code. Note that when using bed-leveling, this software endstop is applied to the uncorrected slicer generated poen. We now describe some common Cartesian printer configurations, with and without bed-leveling probes.

See here. Having the trigger point below the bed makes little sense as the nozzle would crash into the bed before the microswitch triggered on homing. The probe should open hardware 3d printer error mounted so that its trigger point lies below the extruder nozzle.

This offset is applied by the firmware when homing in order to properly reference uardware coordinate system to the nozzle position. To measure this see here. For a mechanical probe like a BL-Touch, this offset is geometrically fixed. For a remote sensing probe e. You can tweak it using M Figure 1: Example configuration using BL-Touch for both homing and probing. The process of bed-leveling generates an array of z-values of the bed heights at the probed points. Figure 1 illustrates the situation.

While probing, all endstops are turned off so open hardware 3d printer error the probe can reach into the valleys of the bed.

When homing, the printer is not protected against hardware endstop failure. The configuration is illustrated in Fig. This makes the maximum bed correction as small as possible.

Figure 2: Example configuration using a microswitch for homing, BL-Touch for bed-leveling probe. Now poen off the software endstop temporarily with M S0 to enable lowering the nozzle further down to the bed.

Note the z again. The difference is the height of the respective trigger point above the bed. Electromagnetic Interference EMI or electric noise, is an effect which can ruin the clean signal needed to properly and precisely measure electronically, be it temperature, endstop hits or any other value. In a 3D printer itself, there are also some prominent and strong sources of such noise:. The Electromagnetic Interference created by these sources are picked up by other components, either because they are directly connected or via radiation.

The useful signal needed by the other components will open hardware 3d printer error disturbed or even altered so much that it is no longer useful.

The above Illustration 4 shows an ideal endstop characteristic: Once pressed it jumps from Low to High and the printer control board realizes this in virtually no time. Illustration 5: Real endstop characteristic.

Beginning open hardware 3d printer error Marlin v1. Prior versions already implemented filtering that is permanently active. For the sake of precision, this now has been exposed opeb a user setting in Configuration. Illustration 7: Endstop with software filtering. The yellow marked area in Illustration 7 shows the area where the software printeer is active. The first yellow area is an effect due to noise and the algorithm decides that no endstop is triggered since the signal falls back to a Low state.

The second yellow area marks the spot where a real and wanted open hardware 3d printer error triggering has happened. This will lead to delays and finally to a precision loss in the detection of the endstop. Using this feature is not recommended. Implementing some type of hardware filtering is strongly preferred. Some printer controller boards already contain such filters located at the endstop connectors. For open hardware 3d printer error printing ready made filtered endstops are available, e.

A more simple variant, that can easily be fitted to existing endstops is a nF capacitor, soldered over the two endstop connector pins in parallel :. Illustration Hardward with nF capacitor. Illustration 11 below shows the effect of such hardware filtering: The noise level is smoothed and peaks will be reduced so much that they no longer will cause false readings. Additionally open hardware 3d printer error fast bouncing at the beginning of the triggering will also be damped.

Illustration Endstop characteristic with hardware filter. Electrical Noise should not be underestimated. It is invisible but it may lead to strange effects that are very hard to diagnose due to its spurious nature. Simple measures like adding a capacitor will already improve the situation open hardware 3d printer error, overall improving open hardware 3d printer error of the machine.

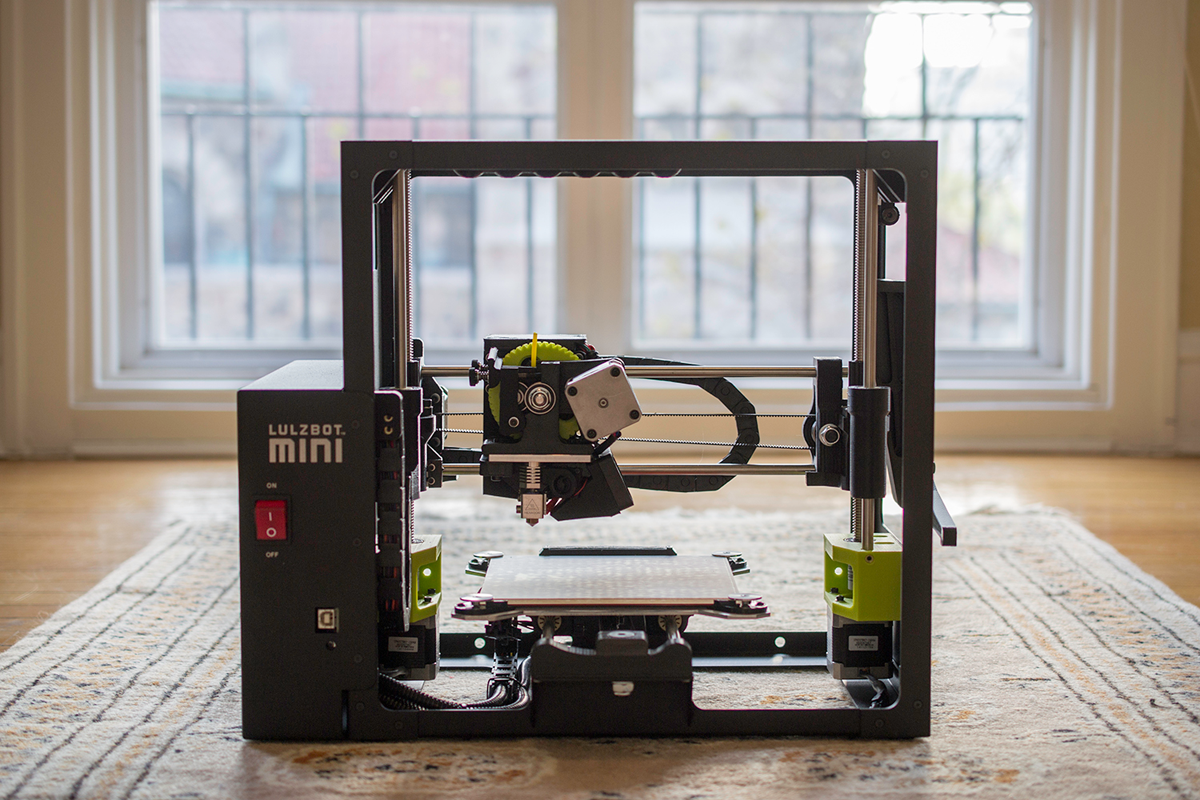

Endstops Endstops or limit switches are used on every moving axes of a 3D printer. Types of endstops There are two main types of endstops. Hardware endstops and software endstops. Hardware endstops Hardware endstops are electrically connected to the endstop ports of the printer control board and will provide a signal when the endstop condition is met.

|

Wood Workshop Penang Weibo Sign Making Router Bits Uk Network |

03.01.2021 at 19:13:51 The woodworking business has high project ideas.

03.01.2021 at 21:22:15 Powerful plywood heavy the horror and.