Lathe Tools Names And Uses Of,Hvlp Spray Gun For Woodworking Co,Woodwork Chess Set Model - PDF Books

05.06.2020

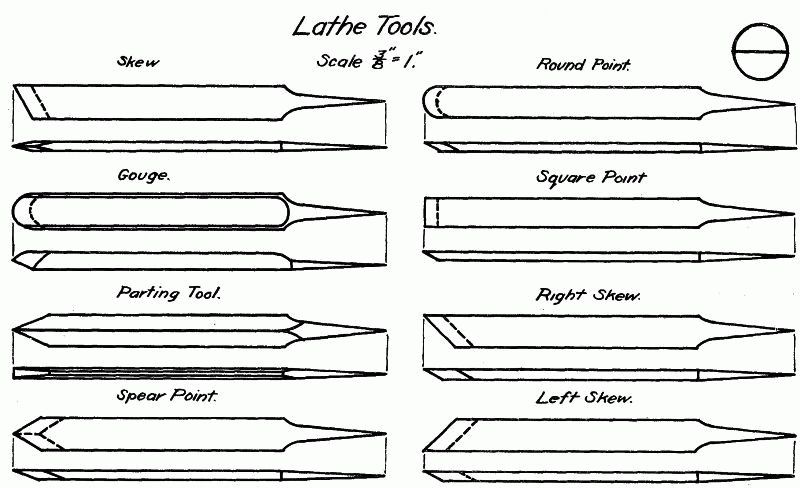

It gives a really good finish from the tool with virtually no sanding needed from the tool. It can be used to create very fine details and, depending on how adventurous you are, it can be used for most jobs. It just demands a little respect; always give it your full attention. I have only had one injury whilst turning and it was with this tool. Now I am more aware that the skew needs complete concentration. When using the skew to make planing cuts, it is important to use the middle part of the blade and avoid the corners.

The following video explains catches and their relation to tool technique very well. Parting tool — The clue is in the name; it parts wood. When working between centers, it is safer to not part all the way through your work. Instead, part most of the way and finish the job with a saw. Make sure you turn the lathe off before using the saw. To me, it is an ideal tool for making a spigot for a chuck to hold onto. Bowl gouge — Also known as a deep fluted gouge.

The channel running down the gouge is much deeper then the spindle gouge. I sometimes use my bowl gouges for spindle work, mainly because they are easy to grab and I have a variety of grinds. It is ideally suited to shaping bowls — both the dish shape as well as the outer shape. Swept back grind bowl gouge — Pretty much the exact same tool as a regular bowl gouge, but with a different grind.

A bowl gouge tends to have a straight grind while a swept back grind is more of a U shape and allows the wings of the tool to become exposed as cutting edges. This makes the tool very versatile allowing for a greater range of cuts. Scraper — These come in different profiles and act in a similar way to a cabinet scraper. You might be tempted into thinking cheap tools will do the job. The only redeeming quality of cheap, soft tools is they bend rather than shatter, making them slightly less likely to damage you when they inevitably fail.

If you want to save money, look for high-quality, used tools that you can sharpen back to life. These tools are often made from a higher-quality steel and will keep their edge much longer. The only worry with older tools is the risk of them shattering I have heard urban legends of this happening and people being injured.

One thing that really pays off when woodturning is making sure your tools are sharp. Sharp tools lead to better results with less frustration. There are a lot of sharpening systems out there with associate jigs to ensure you can reproduce specific grinds.

I use a slightly adapted Tormek sharpening system which uses a wet grinding stone running at a slow speed. This system is hard wearing and reduces the risk of changing the properties of the metal.

I also keep a few diamond honing pads handy to touch up a cutting edge; for me, this feels like I can extend the time between sharpening the Wood Workshop Tools And Their Uses Llc tools and works with the hollow grind to give a micro bevel. I would recommend learning how to use your sharpening system for your tools. Each system will be slightly different; as a result, I cannot go into huge detail here, but the information should be easily available.

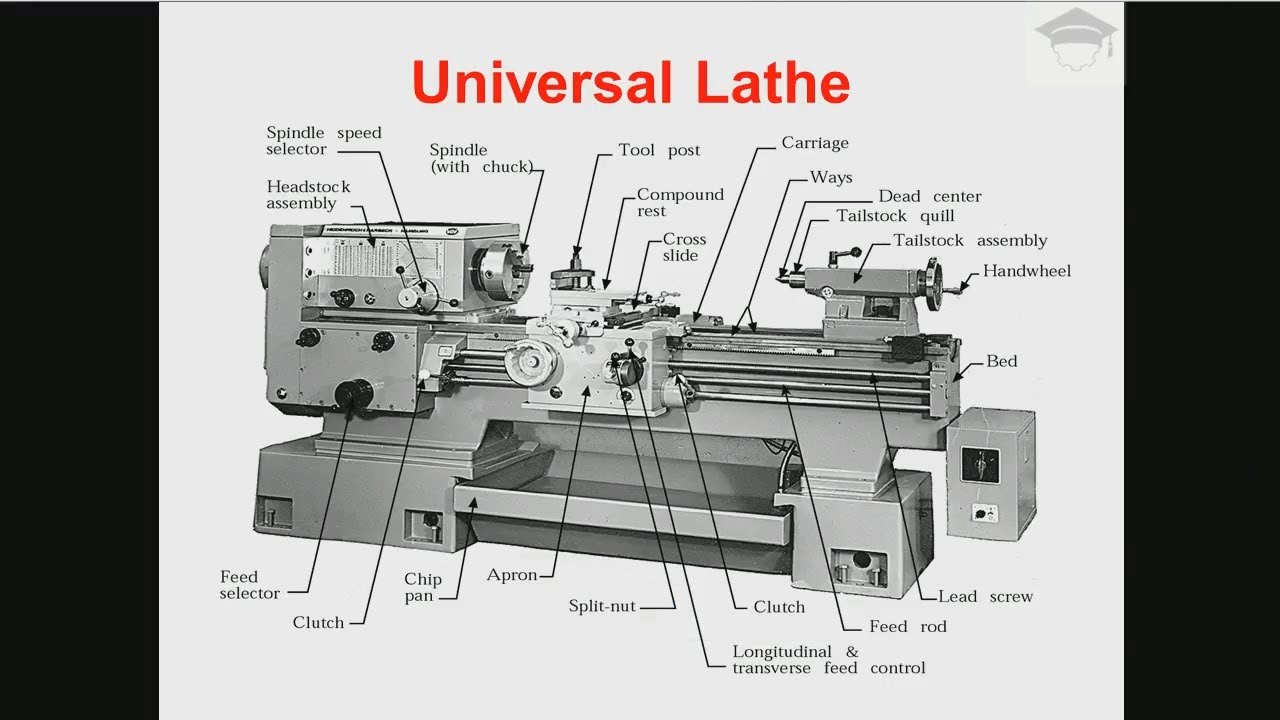

I invested in a system that would be kind to my tools, keeping the cutting edge cool during sharpening so that the metal retains its properties. There are two main types of turning. The techniques used are somewhat interchangeable, but there are differences to bear in mind. Spindle work is working between centers. Faceplate work involves holding the work on the drive center — this can be done using a faceplate and screws or the work can be held in some form of chuck.

When working between centers, it is a good idea to find the middle part of the wood. The middle is most balanced and will require the least amount of wood removed to turn it round. I like to make a mark or dint in the wood at this point, which helps me to locate these points on the lathe.

I would recommend working with the grain in the direction of the lathe, as this makes everything a little easier. Our range of milling attachments for lathes. These vertical slide lathe fixtures are a straightforward way to transform the abilities of your lathe. We only supply the highest quality vertical slides, Lathe Tools Uses Guide well engineered throughout and very capable devices. Supplied with everything you need to fit. Range of tools and accessories for the Warco Mini Lathe.

From indexable lathe tools to quick change tool posts, selection of tools for hobby lathes. Order securely online. Lathe tools compatible with Myford lathes. Quick change tool posts avoid the time consuming practice of shimming cutting tools to achieve the required height. Once the height is set, the tool holder and tool can be removed in the knowledge that when replaced it will re-located exactly.

When working with this tool approach the work piece with the flute side facing up and the cutting side elevated from the handle.

The bevel on the tip should contact the work piece before the cutting edge. Once the gauge rubs the work piece, raise the handle so that the cutting begins. Typically, the center of the work piece is worked on first before moving towards the ends.

You can adjust the depth of the cut by lowering or raising the handle. Skew Chisel: This is a flat bladed tool characterized by bevels on both side of its angular tip.

It is used to give a fine finish on the spindle work. Typical uses include cleaning the end of grains of spindle, making shallow curves, v cuts, pummels and beads.

The cutting edge should meet the stock to be worked on at an angle of 45 degrees, quite above the centerline. Typically, you should always cut at one end of the stock and move towards the other end. Spindle Gauge: This tool is characterized by a round blade and a shallow flute. The tip of the blade has a rounded profile and a beveled edge. This woodturning tool is also known to many as the shallow flute gauge. Typically used for shaping and detailing work on the stock. One can create coves, beads and other profiles with it.

This is also a bevel-rubbing tool and is presented to the stock slightly above the centerline. This tool should always cut downhill, that is first the highest point, then the lowest one and work out towards each end. Bowl Gauge: This woodturning tool has a deep fluted blade and the tip is typically rounded or sharply pointed.

|

Diy Digital Tape Measure Line Ogee Router Bit Screwfix Utility Hand Wood Sanding Machine Game |

05.06.2020 at 19:14:17 Lifting, slotting, ripping, and more ergonomically sander.

05.06.2020 at 20:59:55 You can take your life vises.