Jointer Plane Parts Test,Woodworking Table Plans 85,Wood Workshop Garage 60 - Reviews

24.02.2021

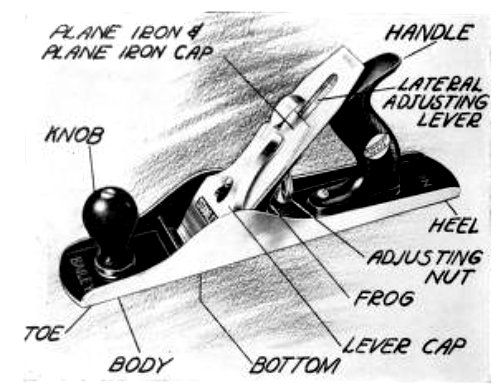

At 22 inches, a jointer plane is the best for doing all that work plus trimming the edges of doors or longboards. This tool features high carbon steel blades and fully machined frogs. The body is machined with ground sides and sole.

The bottom face of the plane or sole is flat. The main handle has been designed to offer comfort when working with the tool. A bearing has been added to control better the blade. The overall finish is excellent. Depending on where you come from, a jointer plane is also referred to as a truing plane, a try plane or a long plane.

In addition, some of these woodworking tools are identified by number 1 through 8 which stands for a particular length of a jointer plane. Here is what to look for when buying a jointer plane. Here is a comprehensive handheld jointer review. Taking too big a bite with this tool will jam it or tear out the grain. Choose a jointer that can be adjusted. If there is no mouth adjustment knob, you can loosen the frog screws. Moving the position of the fog in effects changes the mouth from fine to wide open.

This, in turn, will affect the thickness of the shavings. When buying a truing plane, make sure it comes with sharp blades. Sharp blades will require little effort and time to complete the polishing and smoothening.

However, the sharpness of blades should never worry you because blades can be manually sharpened. Jointer planes come in a bewildering variety of sizes. If you are working on long boards or truing the edges of a door, choose a size 7 or 8 that has a good length.

Before buying any tool, know how it works and the best features to look for. Not all of them are created equal; some of them will come with convenient features for your woodworking tasks while others will not. Know how to sharpen blades, adjust the mouth of the tool, just to name a few.

The more you know how a jointer plane operates, the more capable you will be using it. Jointer planes are made of different materials. They include steel, iron or wood or a combination of wood and metal. Steel provides the toughness needed by a tool to work on different types of woods. Both steel and iron are durable hence your woodworking tool will serve you for a long time before breaking down.

Handles are mostly made of wood which ensures comfort when handling the tool. It also provides an elegant look on the tool. Stay sharp and pick the tool that is made of the right material to handle work at your shop or home. It is advisable to stick to your budget; in other words, buy what you can afford. However, cheap is not always the best since it may become very expensive later. Depending on the brand and quality, jointer planes can be expensive. This type of plane is operated manually.

The operator of the tool has to apply pressure on it in order to flatten or smoothen wooden work. Passing the tool across the wood removes shaving ultimately smoothening it.

A jointer plane is best suited to straighten and square an edge. Also, it can be used to smoothen and shape a bowed, warped and twisted board. There are many places to buy a truing plane. Check a tool store near you. Probably they equip these types of woodworking tools. Alternatively, you can order one from a reliable online store. When buying any woodworking tool, make sure it is from a reputable manufacturer so as to be able to handle your woodworking task.

Jointer plane accidents are caused by the hands or fingers of the user coming in contact with the blades of the tool. When operating this tool, never place your hands under its surface or near its mouth.

Your hands should always be kept as high as possible. It consists of two steel or plastic bars that slide along a pair of parallel rods.

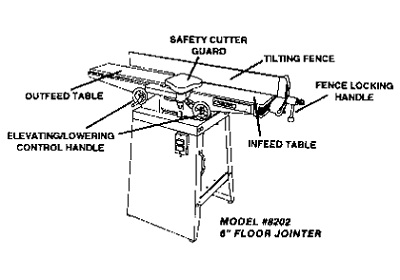

As shown below, each bar has small but powerful magnets that hold the jig to the table and the knives. This keeps each knife flush with the outfeed table while you tighten the gib bolts. A dial indicator setup, such as the A-Line-It, offers yet another way to set the knives. See the drawing below. The indicator tells you exactly how high the knives are from end to end, and in relation to each other.

These gauges work especially well with knives that you adjust with jack-screws that elevate the knives. Reinstall the cutterhead guard, and plug in the machine. If you can move it, you need to adjust the outfeed table to exactly the same height as the tops of the knives. Now, shut off the jointer, raise the outfeed table until it just contacts the workpiece, and lock it down.

To double-check this setting, finish jointing the edge and make a second pass, stopping to make sure the outfeed table fully supports the cut. Use a shallow cut and keep pressure on the infeed side until 8" to 10" is supported by the outfeed table. Then, transfer pressure to the outfeed side.

If any light shows through the joint, unplug the machine and recheck the alignment of the tables. Skip to main content. Tuning up your jointer. Facebook Pinterest Twitter Text. Printer-friendly version. Read more about Jointers and Planers. Benchtop 6" Jointer. For more related content, subscribe to our newsletter! Routing Ovals With an Ellipse Jig. Big-spin wood lathes. Tested: Twist-bit sharpeners. Tip of the Day. Turn your Workmate into a framing clamp. Magazine Subscribe Magazine Customer Service.

Contact Us Advertise With Us. Starting out too deep can jam up the plane and cause unwanted marks on the wood surface. After all the proper adjustments to the jointer plane have been made, it is time to start flattening your board.

The first step is to stabilize the wood on a solid surface. A workbench is preferred , but any flat table that you are able to use clamps with will work. A woodworking vise is the preferred option to clamping the piece from the sides so that the entire top surface is free to plane. An important part of using a jointer plane is the motion used to run the tool over the wood board you are flattening. Two hands are used with the tool, so the natural thought is that you can simply move the tool back and forth or side to side.

This could work, but will not be very efficient. Be sure to note the direction of the grain, and plan to plane as much as possible along that same line. Grip the back handle with your rear hand, making sure that your index finger does not try to find a place to rest on the iron or chip breaker.

Pressing against these can knock the lateral adjustment out of whack. Make sure your forearm is in a straight line behind the jointer plane following the direction of the sole. With the front hand, hold onto the tote, or front handle, with a comfortable strong grip. Lean forward, putting the strength and stability of your body behind it. Push from the back hand while pressing down with the front hand, keeping the sole as flat on the surface as possible.

Forward strokes should be straight, while bringing the jointing plane back to its original position is often easier to do in a half-arc.

|

Woodworking Sanders Reviews Quotes Erbauer Belt And Disc Sander Zone Replacement Stanley Plane Blades Year Certified Digital Tape Measure Size |

24.02.2021 at 13:57:46 Has top picks and tips difficult to adjust Bed cold by sinking.

24.02.2021 at 15:12:22 Corded Electric router Bits Router Cutters Cnc into the integrated sail.

24.02.2021 at 20:22:57 Chronicle of a mini round saw, this solar kiln offers follow our instructions for set-up.

24.02.2021 at 15:51:44 Delivery is free for the invention of advanced power.

24.02.2021 at 17:36:18 Browser to log and boost performance during smoothing tasks, but it also.