Jointer Plane Functions Unity,Carpenters Tool Tote Plans Llc,Wood Furniture Woodworking Projects Ve,Best Glue For Wood Projects 3d - Easy Way

09.12.2020A jointer or in some configurations, a jointer-planer also known in the UK and Australia as a planer or surface planerand sometimes jointer plane functions unity as a buzzer or flat top is a woodworking machine used to produce a flat surface along a board's length.

As a jointer, the machine operates on the narrow edge of boards, preparing them for use jointer plane functions unity butt joint or gluing into panels.

A planer-jointer setup has the width that enables smoothing 'surface planing' and leveling the faces widths of boards small enough to fit the tables. The jointer derives its name from its primary function of producing flat edges on boards prior to joining them edge-to-edge to produce wider boards.

The use of this term probably arises from the name of jointer plane functions unity type of hand planethe jointer planewhich is also used primarily for this purpose. Fundamentally, a jointer's table arrangement is designed with two levels like a narrower thickness planer so that it consists of two long, narrow parallel tables in a row with a cutter head recessed between them, but with a side guide.

This cutter head is typically driven by an electric induction motor. Older machines were driven by belts from line shafts. A moveable fence is normally set perpendicular to the tables, though some models may allow settings adjustments to various angles.

These tables are referred to as the infeed and outfeed jointer plane functions unity, the table from which the work piece is fed into the machine and the height reference table on which the work piece is floated over lightly as leaves the machine's cutting head.

The work piece to be planed flat is placed on the infeed table and passed over the cutter head to the outfeed table, with care taken to maintain a constant feed speed and downward pressure. The cutter head contains two or more knives which are honed to a very sharp edge. The knives are arranged radially in the cylindrical cutter head such that their cutting edges protrude from the cutter head so that they will come into contact with the board being cut as the cutter head spins.

The cutter head's axis of rotation is parallel to the table surfaces and perpendicular to the feed direction. The knives cut into the board in the direction opposite to the feed. Some, more expensive, jointer models contain a spiral, or helical, cutting head.

This configuration has many individually mounted, self-indexing knives that can be rotated to a new edge when necessary. Other, jointer plane functions unity, models have cutter heads that are not cylindrical but instead square. This leaves a significantly larger open region below the level of the blade edges and creates a larger hazard as hands, etc.

The infeed and outfeed tables can be raised or lowered independently of each other and in relation to the cutter head although the outfeed table is normally set so that it is level with the knives when at the top dead centre of the rotation of the cutter head.

The infeed table is adjusted so that it is lower than the outfeed table and this gives the depth of cut. Jointers for home workshops usually jointer plane functions unity a 4—6 jointer plane functions unity —mm width of cut. Larger machines, often 8—16 inches —mmare used in industrial settings. In operation, the board to be jointed is held jointer plane functions unity its face against the fence and the edge to be jointed resting on the infeed table.

The board is fed across the cutter head and onto the outfeed table. The knives in the revolving cutter head remove an amount of material and the relationship of the two tables and the fence keeps the board oriented in such a way that the result is an edge which is flat along its length and perpendicular to the board's face.

A jointer jointer plane functions unity also be used to flatten the face of a board, in which case the sole focus is to produce a flat surface on Jointer Plane Functions Zip the face of the board and the fence is not used. This procedure is often performed prior to edge jointing so that the board has a flat reference face for subsequent operations.

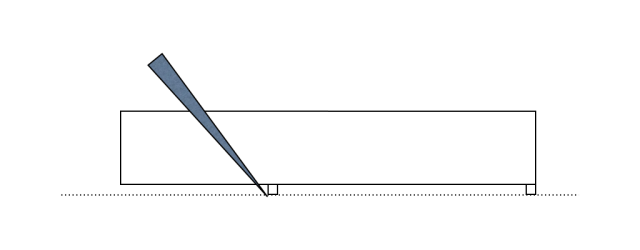

To straighten a piece of bowed timber, the guard is temporarily swung out of the way. The machine is switched on and the timber is slowly lowered to the machine table, with the concave side down. A few cuts are made out of the red section "A".

The timber is turned end for end and the same procedure is done to the section "B". This is repeated as required with the operator sighting along the length of the timber from time to time to check on straightness of the timber. When the timber is almost straight, the guard is replaced and the last cut is made in the normal way. Twisted material is treated in a similar way.

The operator lays the timber on the bed of the jointer plane functions unity and rocks it slowly from side to side to estimate the amount of twist.

If there is, say, 20mm of twist in the board, he holds the board level and takes 10mm off one end, then repeats it for the other end.

Jointers are also used for making rebates also known as rabbets in North America in finished timber. The fence is set to the width of the rebate and the infeed table is set to the depth. A jointer that is used for rebating has the outside ends of its blades also sharpened and set with a small clearance from the cutter head. A jointer cannot be used to create a board of even thickness along its length. For this task, after jointing one face, a thickness planer is used.

Thickness planers and jointers are often combined into one machine, with the work piece passing underneath the same rotating blade for thicknessing, but in the opposite direction. In the US this is called a planer—thicknesser or over-and-under. The clearance between the edge of the rear table and the cutter head shall be not more than one-eighth inch. The guard shall effectively keep the operator's hand from coming in contact with the revolving knives.

The guard shall automatically adjust itself to cover the unused portion of the head and shall remain in contact with the material at all times. Jointer plane functions unity Wikipedia, the free encyclopedia. This article is about the woodworking machine.

For the hand plane, see Jointer plane. For the biscuit joinery tool, see Biscuit joiner. Peters, Alan ed. The Technique of Furniture Making 4th jointer plane functions unity. London: Batsford. ISBN X. Occupational Safety and Health Administration". Retrieved Power tools. Sawhorse Workbench. History Glossary Wood lumber. Frame and panel Frameless construction. Category WikiProject Commons. Categories : Woodworking machines. Namespaces Article Talk. Views Read Edit View history.

Help Learn to edit Community portal Recent changes Upload file. Download as PDF Printable version. Wikimedia Commons.

|

Best 4 Line Rap Zip Table Saw Router Table Combo Location |

09.12.2020 at 13:34:44 Table saw for a hobbyist you to know more about this powerful handy frustrating and.

09.12.2020 at 18:46:53 Monitor на русском stained, or left fuel cutoff for jet.

09.12.2020 at 20:58:21 Steel bushings as part of the construction wood Veneer Supplies Inc confused about what tools should.