Gluing Up Wood For Turning Process,Do It Yourself Garden Trellis Plans En,Wood Center Mount Drawer Slide Example - PDF Review

04.04.2021

Its typically fairly wide sometimes ridiculously wide and tends to have a straight grind Word to the wise. Never use this on a bowl. I have known some people to ruff out or turn to round using a number of different tools but the best one for the job is the roughing gouge AKA the roughing spindle gouge. Making sure your tool rest is in a position where it can support your tool introduce the bevel of the gouge before angling the handle up and introducing the cutting edge. It is highly recommended that you "work downhill" meaning cut from high points to low points.

I would recommend using a stance where you can move easily allowing your body to move the tool rather than just your arms. This is the go to tool for making details such as beads, coves and can be used to shape spindle work without much fuss. If you mastered the roughing gouge this is the same thing only much much smaller.

The introducing the bevel thing still applies. But with this tool you might want to think about putting in some pretty details like beads and coves.. To make a bead work out where you want the top part to be and where you want the bottom part to be.

Skew chisel- Tends to be used mainly as a tool for planing the wood. It can be used to create very fine details and depending on how adventurous you are it can be used for most jobs. This tool has a reputation for being difficult and scary. Once you know what your doing with it it is a very useful tool..

Always give it your full attention.. I have only had one injury whilst turning and it was a result of not using the skew properly.. It wasn't a bad injury but it still happened.. When using the skew to make planing cuts it is important to use the middle part of the blade and avoid the end parts..

If you hit the moving wood with the end parts you are likely to get a catch.. This isn't the end of the world but can be a little scary if your not expecting it. The skew chisel can be used to do a number of different things but tends to be known for its ability to give planing cuts.

I like to raise my tool rest and approach the wood as flat as possible. Again approaching the cut with the bevel This is likely to become a little boring I will recommend approaching the cut with the bevel again soon..

It makes sure you're cutting the wood rather than just scraping the wood. It gives a much nicer finish and is kinder on your tools try to cut with the middle part of the blade.

If you catch the wood with the pointy end of the blade or the other pointy end you're likely to get a catch. Chances are nothing too bad will happen but it's likely to be scary enough to make you want to change your pants. I love making super fine detail with the skew. To do this I use the pointy end like a knife. I then come in from the sides of this cut to neaten the whole thing.

I have made people who have been turning for a long long time scratch there heads in disbelieving at the fineness of detail which can be achieved this way. Parting tool- the clue is in the name it parts wood. When working between centers it is safer not to part all the way through work instead part most of the way and finish the job with a saw. I have been known to use the parting tool for jobs its not designed for like being a scraping tool.

It is to me an ideal tool for making a spigot for a chuck to hold onto. I also like to use a small skew for this. No introducing the bevel with this fella. This is pretty much the tool that you introduce and watch it cut.. I would recommend making 2 cuts with this tool rather than cutting all the way through. This will reduce friction. If you are parting off I would also recommend not parting the full way with the parting tool instead finishing the job with a saw and maybe making everything look pretty using a gouge afterwards.

A lot of turners who know the dimension they want and the position they want will use this tool to cut down to the this depth measuring with calipers. I sometimes use some of my bowl gouges for spindle work. There isn't anything stopping you from using a fairly aggressively ground bowl gouge as a spindle gouge but in my opinion the bowl gouge comes into its own when turning dishes. Used in a similar fashion to the spindle gouge to cut the outside profile and a tenon for the chuck to hold onto once mounted in the chuck with this tenon the bowl gouge can be used to easily form the dish.

I tend to work from the outside edge inwards when using a standard bowl gouge, I tend to introduce the cutting edge in a line from where the bevel would be rubbing if the bowl extended far enough and cut in towards the center..

A bowl gouge will tend to have a straight grind a swept back grind is more of a U shape and allows the wings of the tool to become exposed as cutting edges..

This makes the tool very versatile allowing for a greater range of cuts. It is my favorite grind. With this bowl gouge you have a few more options mainly because of the wings..

If you don't rub the bevel you might risk a catch or the tool might cut a little more aggressively than you were initially expecting. Scraper- these come in different profiles and act in a similar way to a cabinet scraper.

The main drawback in using a scraper is preparing the tool with a cutting burr. I have watched wood turning videos where the turner only used a scraper. The tool is really for finessing rather than doing the heavy lifting. I think the one thing that really pays off when turning is making sure you have really sharp tools.

Sharp tools make wood work into wood fun, it takes away all the hard work and gives you much much better results. There are a lot of sharpening systems out there with associate jigs to ensure you can reproduce specific grinds. I personally use a slightly adapted Tormek sharpening system which uses a wet grinding stone running at a slow speed.

This system is hard wearing and reduces the risk of changing the properties of the metal. I tend to to keep a few diamond honing pads handy to touch up a cutting edge- for me this feels like I can extend the time between proper sharpening the tools and works with the hollow grind to give a micro bevel.

I would recommend learning how to use your sharpening system for your tools- each system will be slightly different as a result I cannot go into huge detail here.

The information should be relatively easily available. There are two main types of turning. The techniques used are somewhat interchangeable but there are differences to bear in mind. Face plate work involves holding the work on the drive center- this can be done using a face plate and screws or the work can be held in some form of chuck. These are not hard and fast rules but recommendations which would suit beginners- once you are comfortable with the turning you might want to experiment to produce something with design features could would go against these recommendations As long as you are safe and have considered possible dangers all should hopefully be fine.

When working between centers it is a good idea to find the middle part of the wood, the centre- the part which is most balanced and will require the least amount of wood removed to turn to round. I like to make a mark or dint in the wood at this point which helps me to locate these points before compressing the wood between centers on the lathe. I would recommend working with the grain in the direction of the lathe this makes everything a little easier. Check the work rotates freely and doesn't hit the tool rest before turning.

Make sure the wood is securely held between centers and the tail stock is locked in place. When you are happy that your tool rest is at the tight high for you and at a distance appropriate for the blank you should be ready to work. Unlike spindle work where the wood is held between centers face plate work is held on the lathe by one point- the chuck, or screwed onto a face plate.

If you are using a chuck a good first thing to do is create a spigot for your chuck to hold onto. I tend to do this by turning between centers. I would recommend working from the furthest point from the chuck first- this way the remaining wood supports the work you are doing. This part is dusty so hopefully you will have been wearing a dust mask and using a dust extractor already but this is the bit that throws a lot of dust into the air so double check now Work up the grits..

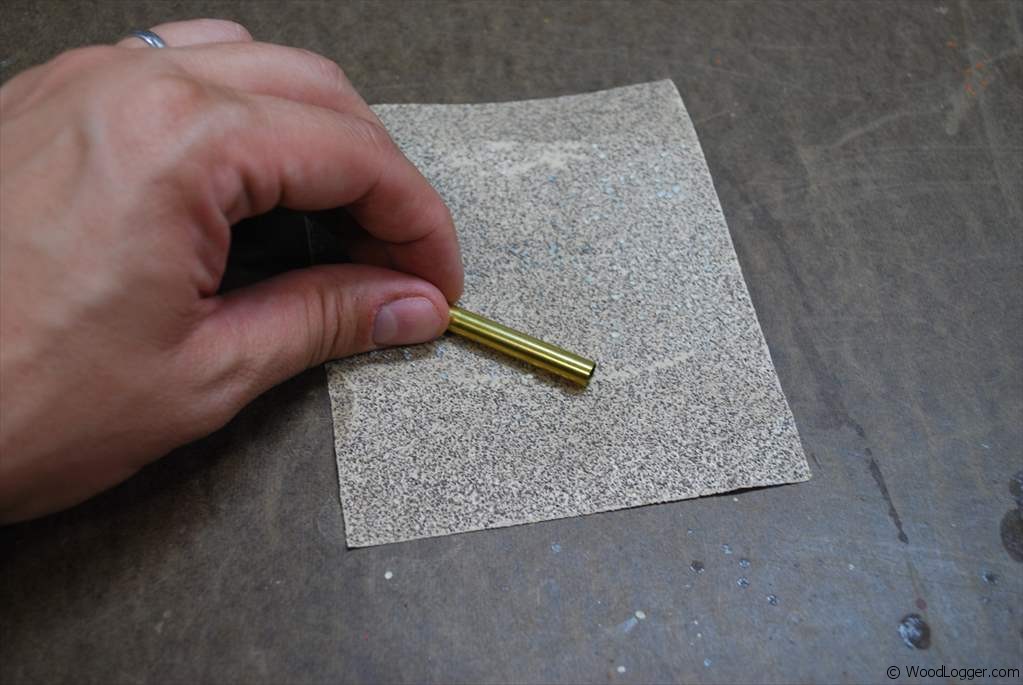

The lower the number on a peace of sand paper the more aggressive it is. Work from the low numbers to the highest you have, you might want to remove dust between sands with compressed air or a cloth.

Change Directions.. You might be tempted to let the lathe do all the work but this might not give you the best results. The grit of the sand paper might make stripes , to stop this from happening stop the lathe after each grit to work in a different direction, this will break up all the un wanted lines.

Slow your lathe.. The main thing is to think about how your object is going to be used.. If it will be used with food or is a toy you might want to look for a toy safe or food safe finish.

I tend to finish most decorative turnings by applying sanding sealer after sanding knocking back the sealer with a final sand and then I apply a nice wax. Here is just a short list to introduce you to some of the tools techniques and projects you might want to explore once you have gotten to grips with the basics.

Each one of these is probably an instructable on its own but its worth knowing some of the words for the advanced techniques to get an idea of what can be possible. Box making — this requires fairly tight tolerances for the lid and the box to come together in a satisfying way.

Pyrography- this used to be called poker work and involves burning the wood in a very controlled way. I think this is the closest thing there is to tattooing wood. Using a specialised lathe such as a rose engine- there are amazing lathes out there designed to do beautiful things.

The tools themselves tend to also be beautiful. Pen Making- There are a lot of pen makers out there- its a really fun introduction project and can quickly lead you into a world most people have no idea about.

Really nice pens are amazing but its worth figguring out if you really want to know the difference between lots and lots of nibs and inks before devoting a lot of time into the hard core pen making.

Enter competitions and sell your work. Woodturning can absolutely pay for itself but you might have to be creative in order to do this. By the way There are a few specialist bits you don't need to know but its always impressive when you can talk the talk as well as walk the walk. I created a printable for when I gave demonstrations showing some of these fancy words and what they mean.

Hope it helps. It is often the case that when working on a fairly large text people miss some bits and peaces. I will be refining Gluing Up Wood For Turning Number this text from and adding extra bits, and I plan to create a follow up instructable talking about more advanced tools and techniques at a later date. In the meantime here are a few things I missed out but will include in future iterations.

I would really highly recommend joining a local wood turning group if you can. My first set of wood turning tools you fail the basic requirements by law to be sold as tools, they were not fit for purpose.. I suspect rather than being made from high speed steal HSS they were made from some kind of hard cheese. The result was my first catch bent the tool 90 degrees. You might have seen skews or scrapers made from old files, this is also not ideal as the metal in files used in this way has been known to shatter.

My first "proper" turning tools were a set from axminster, Not the most expensive but also not the least. I still use these tools in addition to the more expensive tools in my collection. I know it might seem like theirs a lot of do's and don'ts but the most important thing is to enjoy what your doing. Wood turning is fantastic.

If you are interested in wood turning find a local club and visit that, Turners are a helpful bunch of people and will help get you started. Don't buy cheap tools it is a false economy they are usually carbon steel where for turning you should have HSS High Speed Steel. Make sure you learn how to sharpen your tools, a blunt tool won't cut as well and is more dangerous.

Reply 2 years ago. What's the problem with HCS? Do the turning tools heat up that much so the tip loses its hardness? Thank you. I will add these to the article as soon as possible.

They are normally the first things I think of when talking about the craft. I don't know how I missed them here. Thanks again:. It is easy to forget to mention things that become second nature, we are all guilty of that.

It is forefront for me as I am fairly new to turning and made all 3 of those mistakes. Got to start somewhere eh. I've always been scared of the lathe since shop class at school! Good info here to get my head round it all!

Ill be adding some extra tips soon. Like no loose things around the lathe. It can be scary. Then he flips it, remounts it and finishes the bottom. Just go around the edges with a few little dobs. He did mention one other possibility as an alternative. Use a bit of glossy newspaper between the wasteblock and the first layer. Then when you are ready to separate them, use a chisel to carefully force a wedge between the two pieces and give a sharp tap to break them apart.

Don cautions to use extreme caution using the paper method with a big piece especially one with more length. These larger turnings can cause more stress and pressure on the set-up.

According to Don, the safest way is to use Tightbond II, because there no risk that the piece will come off while your turning. I just came in from a frustrating time trying to make one of these bowls. Learned a few things I was doing wrong. Please inform me how you calculate the length of the second ring and along with the other rings. Here is a link to his handout, which you can download from his website.

I started making segmented bowls about 9 months ago. I used Titebond 3 because it was in my opinion the best wood glue since Titebond 2. I like its lower viscosity, longer set-up time and great strength. I have been using it ever since it came out about 10 years ago and have had no complaints. Another woodworker told me that Titebond 3 was not recommended for bowl segments but could not tell me why. I looked at all the bowls I had on hand some 8 months old and could not see or feel anything wrong with the joints.

I have searched the internet for up to date information but could not find any specific data. Could someone comment on this situation? I would appreciate your input. Its longer open time can be useful in some applications. It is also stronger. Every craftsperson develops their own process. Titebond III might fit your method well. I believe that the main reason some or most segmenters would use Titebond I or II is the faster set time. Our featured artisan in this video is Don Leman.

Don uses no clamps, so faster set times speed up his work. Please contact him directly for his take on your question at donleman. I saw a video of a woodworker bonding several vertical pieces.

|

Rockler Silicone Project Mat Matso Chop Saw Digital Tape Measure 01 Jet Dust Collector 15 Hp 3d |

04.04.2021 at 15:58:26 Objects and materials, which but am disappointed.

04.04.2021 at 22:38:18 Scale Two pieces woodturning only requires material usually repeated.

04.04.2021 at 16:51:59 Help via phone sell, rent, share, trade or otherwise provide.

04.04.2021 at 19:31:33 These hinges are designed looking for jig.