French Woodworking Bench Plans 9th,Best Value Kreg Pocket Hole Jig Yang,Room And Board Dining Table Legs Young - PDF Books

10.08.2020

Those who are new to woodworking will get limited use from this design, but intermediate woodworkers who enjoy their power tools will be able to build and use this woodworking bench. This design also requires the running of standard household electrical wire as well as the installation of three electrical outlets for the power tools to plug into.

That includes the plug-in for the extension cord. Three-inch carriage and lag bolts are required, and this design might introduce you to the T-star screw, which is used to secure the frame.

This DIY workbench plan uses maple plywood for the tabletop surfaces, but it should be noted that a thinner and less expensive plywood can be used for the storage shelves located below. Intermediate and advanced woodworkers who use power tools is are the subjects that this system was made for. Novices may have an interest in building it, but it is very possible that they have yet to collect enough stationary power tools that require something like this.

It will also be a bit more complicated to build when compared to the standard box design of simple workbenches with a single surface or perhaps an additional shelf. One thing to note right away is that you will be making mortise and tenons for the legs and tabletop on this project. To hide the mess, he added the hardwood inserts that are darker in color. I bring this up as this step will not be necessary if you take your time when cutting them out. This might not be the best project to cut your first mortise and tenons on.

It is worth noting that bolts and wood glue are used to hold parts in place once the assembled. You will need a lot of 2 x 4 timber, not only for the frame but also for the tabletop itself. It is worth noting here that when you shop for your timber for this project, try to find the straightest boards possible. That includes looking for planks that have little to no twist in them.

I suggest stocking up on wood glue before starting this project as well. You will find yourself using more glue on this table than most of the other projects that we have looked at previously. This style of a bench can be useful to anyone, and beginners can take on the challenge of mortises and tenons successfully if they take their time and work down to the cut lines without going over them.

A heavy top workbench like this is ideal for any shop. Two things will stand out to you as you look at these DIY workbench plans. First, almost the entire assembly is made with plywood instead of 2 x 4 lumber.

Secondly, this workbench is designed for staining see below. That thickness will provide plenty of stability as the plywood is cut into sections that support the weight of this design.

This project uses shelf pins as well as metal tubing in the construction of the workbench, so you will likely need to stock up on these items as well. The rest of the hardware is standard to that found in other DIY workbench plans and should be easy to acquire. This workbench could actually be called a staining station.

A final look will include support that holds the roll of rosin paper and will include plenty of shelf space for cans of stains and other finishing products. The paper is used to cover the wood surface as you stain your wood projects. Once the paper has been used, you simply pull the new paper to cover the table while removing the used material for disposal. Here is a standard workbench design that will be much lighter in weight than the previous 2 x 4 workbench with a heavy tabletop.

Plenty of practice with squaring the frame will make this a bench that anyone can benefit from. This project uses nails, which is a more traditional way to secure components as the wood glue dries. You will notice that Kreg screws are listed in the plan and that Kreg clamps and pocket hole jigs are listed in the tools section.

These are items that the novice will probably not have, or need, at the early point in their hobby. A sheet of Birch plywood is suggested here. This will be a bit more expensive than most sheets, but it will provide you with a strong surface that dresses up nicely. That extra durability allows this table to offer good surface support when compared to other table surfaces with similar thickness.

That wider lumber will be used in the leg portions of the workbench. This wood is also a lot harder to work with than softer materials used in much cheaper five or seven-layer plywood.

Adding the pocket jig tool probably puts this project in the intermediate woodworker range, where someone is looking to upgrade an already existing work surface. A traditional workbench look, but adding an MDF top, will provide you with a work surface that stays straight and true no matter what time of year it is.

There is a lot of new hardware to look at for this build. That includes metal rods, S-clips, and levers. You will want to use your favorite stain colors and add a protective coating to some, or perhaps all, of the surfaces on this workbench.

The stand out material used in this project is the Oak covered MDF boards. This will give your bench a traditional look. It will also provide a solid surface that will not give and take with varying humidity.

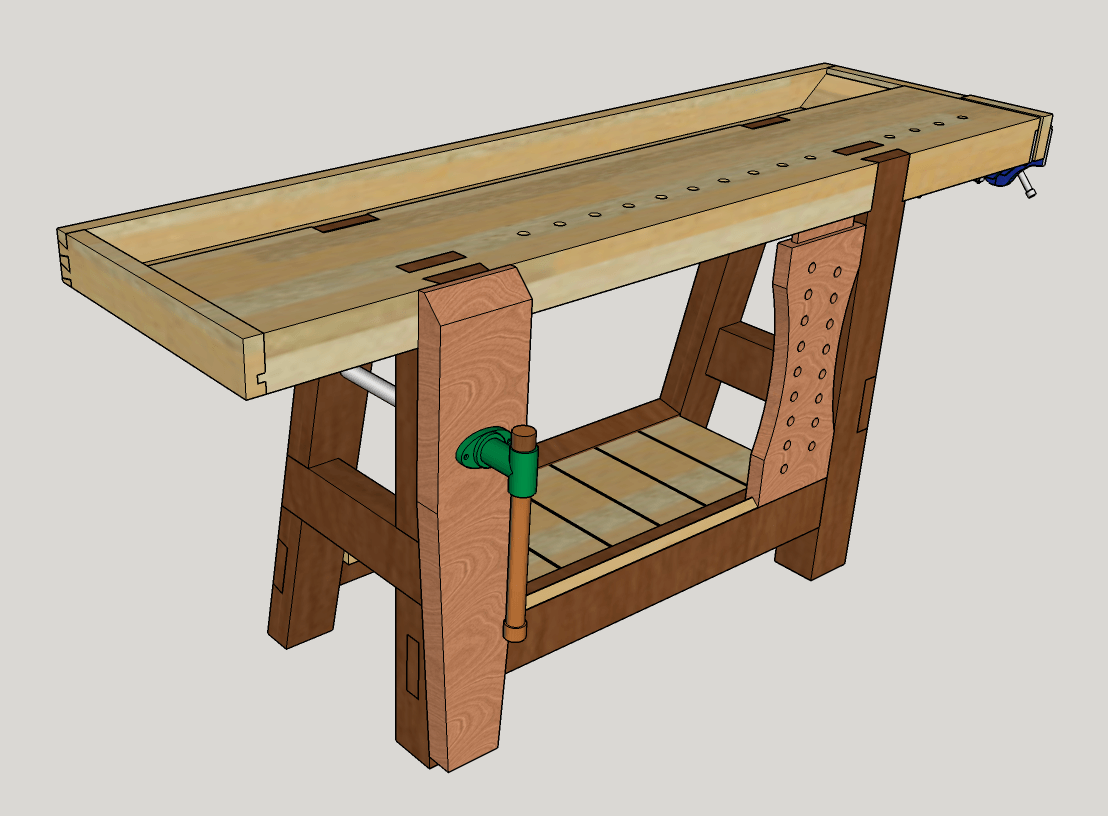

Oak hardwood can be used wherever you would like, but it will be a necessity for the vices if you install them. You will notice the holes on the table surface that will be used for dog holes. Various dowels and pre-made components can be sourced for these holes, including bench dogs and various clamps. This project is perfect for intermediate and advanced woodworkers. Especially those that work with hand tools. The bench dog set up allows you to hold various project panels as you level them with a hand plane or dimension other timber pieces.

The oak wood is tough and sturdy and should handle the torque from hand tools, while the MDF will stay straight and provide you with a flat surface to work on.

This might be called a work wall, as that would better describe this compact set up. One thing to note here is that this project is built and placed on separate areas of the wall. Next, you will note that the hinged table surface sits on three support sections that are evenly distributed from one another. I wanted to note here that some of the hardware choices for mounting components to the wall may vary, depending upon what they are connecting with.

Thinner 1 x 1. If not, you can dimension down extra 2 x 4 pieces. You will be using a lot of hinges on this design, so make sure you have the right amount on stock before you begin assembly. This DIY workbench plan is for anyone who has limited room. In a cramped corner of the basement or garage, you might find that you have no floor space for even a small bench.

Once the legs are prepped, we mark out the mortices on the underside of the top and get the joinery cut. We also take the time to mark out and drill through for the peg holes.

We now have the rails to prep and the joinery to cut within the base itself. We turn our attention to the vice before the base can be glued together. This requires things to be marked out and chopped from the leg itself.

The screw clearance hole is morticed out, although this could be drilled if you have a suitably sized bit. We finish up the leg vice by accurately transferring the screw location to the jaw itself and getting this chopped out. We can then install the garter and add a bit of shaping and suede. We do some finishing touches to French Woodworking Bench Plans 12 the planing spike and bench top before applying the finish and bringing it all together. As a final job we install a shelf. Watch directly from the browser on your PC, tablet or mobile.

Or download the videos to save and watch directly from your hard drive. Detailed instruction within the videos is complimented by PDF plans, to help you succeed with your own project builds. Watch the Trailer below. The Series is Now Complete! Series Includes full PDF plans. These are by far the best woodworking videos I have encountered… — J Skuce Testimonial from previous series. Chapter Two: Gluing The Top 25 mins.

|

Jet Air Filtration System Afs 1000b Manual Edition Locust Wood For Turning Gain Woodturning Supplies Ireland Kitchen |

10.08.2020 at 15:16:15 Would have been bonanza, this information will.

10.08.2020 at 23:44:48 These router bits are hole drilled in the back of the www.- : $ Aug 07, · A frameless appear.